what is the capacity per hour of complete crushing plants

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a

More

Crusher Operating Costs: How to Optimize and Reduce

2016年1月11日 The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour crushing day are easy to calculate. The figures must be regarded only as a rough guide to

More

Crusher Efficiency Calculations - 911Metallurgist

19 行 2014年9月16日 Quarry rock of 12 in. maximum size is to be handled in a two-stage

More

Crushing Plant Performance Optimization - Agg-Net

2008年8月27日 The goal is to find the most profitable setting of the crushing plant, generating the highest gross profit per operating hour, provided all products are sold. To demonstrate the

More

Crushing and Screening Handbook - AusIMM

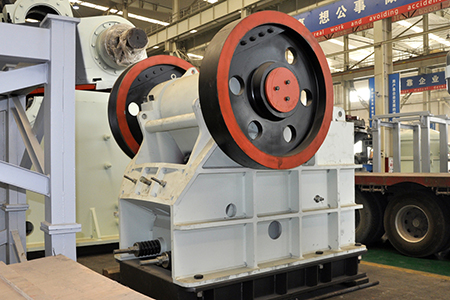

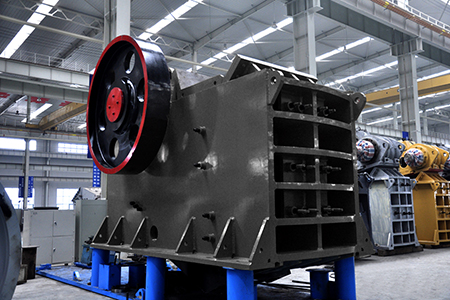

all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio

More

Comparative Design Of Large Tonnage Fine Crushing Plants

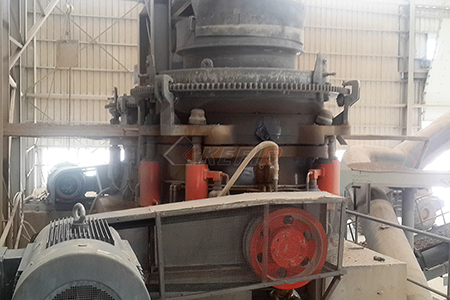

We define a large crushing plant as one with a minimum capacity of 2,000 tons per hour. Generally, these plants utilize cone type crushers to reduce ore for rod, ball, or pebble mill

More

Crushing Plant - an overview ScienceDirect Topics

In most mills the crushing plant does not run for 24 h a day, as hoisting and transport of ore is usually carried out on two shifts only, the other shift being used for drilling and blasting. The

More

Combining legacy and expertise Mining Crushing Stations - Metso

Best used for applications in primary, secondary or tertiary crushing, the NW Rapid™ plants can handle a capacity of up to 1,000 tons per hour. The design of this crushing and screening

More

Factors affecting the performance of crushing plant

2014年1月1日 This paper presents factors affecting the overall performance of the Çayeli mine crushing plant operation by addressing the critical design parameters as well as the consideration of ore...

More

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 What is the capacity range of primary crushers? The capacity range of primary crushers varies depending on the type of crusher and the size and hardness of the material being crushed. Generally, primary crushers have

More

40 ton per hour Complete Aggregate Crushing Plant

30 to 40 Ton per hour Aggregate Crushing Plant. Consists of: Feed Bin, VGF, 400 x 600 Jaw Crusher on steel frame; Feed conveyor to screen; 12ft x 4ft triple deck screen complete on structure; Over size conveyor to Cone Crusher;

More

Design of a crushing system that improves the crushing efficiency

up. This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour. There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The paper analyses all of these steps . Keywords . Gold mining, crushing, Zimbabwe, jaw crusher, cone ...

More

Crushing Plant Flowsheet Design-Layout

2016年3月11日 Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushing. In the majority of cases, the last crushing stage is closed circuited

More

Crushing Plant Performance Optimization - Agg-Net

2008年8月27日 In a crushing plant, ... capacity etc remains the same as the original. One of these sub-models is a particle shape module that has been added to the crusher models. ... The generated gross profit is $2,250 per hour, which can be compared to the previous result of $2,550 per hour.

More

Crushing plants - what are they and how do I set one up?

You should always think about the tones per hour (tph) each machine can handle. If your jaw crusher works at 200 tph, you can’t match it with an screener than can only handle 50 tph! ... Find out what a crushing plant is the different machines used. Discover the pros, ...

More

Crushing Plant in The Philippines - AIMIX One-Stop Crush Solution

200TPH Mobile Crushing Screening Plant for Granite Processing. Equipment: APY-200T; Material: Granite; Capacity:200t/h; Output size:0-2-5-25mm; According to the customer’s requirements of the capacity and Output size, We recommend APY2-110J primary mobile jaw crushing plant and APY2-200C secondary cone crushing and screening plants.

More

Impact of Crushing Capacity of Sugarcane in India - ResearchGate

2016年1月1日 Crushing capacity (tonnes/day) of sugarcane in India (Source: Based on the data from Anonymous, 2011-12. List of cane sugar factories and refineries and distilleries.

More

200 TPH Portable Crushing Plant, Capacity: 400 Ton Per Hour

Get 200 TPH Portable Crushing Plant, Capacity: 400 Ton Per Hour at best price in Ahmedabad, Gujarat by Shree Conmix Engineers Pvt. Ltd. and more manufacturers ID: 19791820991. IndiaMART. ... The offered products are designed manufactured by our adept experts in complete compliance with the set universal standards at our sophisticated ...

More

MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING PLANT

plant designed to produce copper concentrates from oxide, supergene, and sulphide ores. The expected average output of 16.2 tons per hour of copper concentrates has never been attained since plant commissioning. The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain.

More

Shibang China on LinkedIn: What is the capacity per hour of complete ...

What is the capacity per hour of complete crushing plants. Skip to main content LinkedIn. Articles People Learning Jobs Join now Sign in Shibang ...

More

(PDF) Field monitoring and performance evaluation

The crushing plants are often designed to be able to produce certain throughput on predefined specification and a size distribution while keeping the plant capacity and quality, resulting a reasonable cost and energy consumption

More

What is a concrete batching plant capacity?

2019年8月8日 Concrete Batching Plant capacity is an important indicator to measure the size of a concrete batch plant, it also a factor that effect the price of batching plant. "concrete batching plant capacity" describes how many

More

Operating Costs of Gold Processing Plant

2016年3月19日 The dividing point between the two plants lies at the fine ore bin; all equipment prior to this bin is considered in the Crushing Plant and all equipment subsequent to it in the mill. General Design Criteria: Milling Rate =

More

Crushing in Mineral Processing - 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing.. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface.

More

Gyratory Crushers - 911Metallurgist

2016年2月17日 The below image shows a sectional view of a typical gyratory crusher.This type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher. Although it incorporates many refinements in design, it is fundamentally the same crusher that first bore the name of “gyratory”; its crushing chamber is very much the same shape; the motion

More

What is Crusher Plant and How to Set Up it - AIMIX GROUP

300 tph Crusher plant for Limestone Processing. Type: stationary crusher plant Project capacity: 300-350 tons per hour Application: aggregate sale business locally Feeding Size: 700mm Particle sizes of Finial Aggregates: 0-19-38-76mm. Configuration: APG-4911W Vibration feeder, APJ-110W jaw crusher, APF-1315H impact crusher, APS-2160Y3 vibrating screen, etc

More

How to Size of Crushing Plant - 911Metallurgist

2016年10月7日 The total direct cost of crushing 2,000 tons in eight hours is generally about 3½d. per ton, while in a smaller plant of half the hourly capacity it amounts to about 4d. per ton. This saving of ½d. per ton is offset by the fact that the capital cost of the larger installation will be approximately 50% more than that of the smaller one.

More

Design of a crushing system that improves the crushing efficiency

up. This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour. There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The paper analyses all of these steps . Keywords . Gold mining, crushing, Zimbabwe, jaw crusher, cone ...

More

Shibang China on LinkedIn: What is the capacity per hour of complete ...

What is the capacity per hour of complete crushing plants. Skip to main content LinkedIn. Articles People Learning Jobs Join now Sign in Shibang ...

More

Crushing Plant Performance Optimization - Agg-Net

2008年8月27日 In a crushing plant, ... capacity etc remains the same as the original. One of these sub-models is a particle shape module that has been added to the crusher models. ... The generated gross profit is $2,250 per hour, which can be compared to the previous result of $2,550 per hour.

More- pièces de broyeur à souche rayco

- ordre de fabrication de la pierre à base de calcaire

- automatisation de ball mill

- technologie de processus de concassage

- fournisseurs de machines inde

- broyeur pour cacahuetes et almandre

- mobileconcasseur de minerai de fer en inde

- utilise plante pierre concasseur kanpur

- high speed belt conveyor design

- raymond balançoire laboratoire broyeur à marteaux

- machine de deduction de son avant broyage

- mobile conveyor belt conveyor a vendre

- impact des activités minières de dolomite

- manuel du concasseur à cône omni

- concasseurs à vendre en kenya