ball mill for inert gas in Nigeria

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Planetary Ball Mill Lubrication Free 2-year Wty, Inert

Planetary ball mill is designed for fine grinding materials down to nano range. It is also used for mixing, homogenizing, and mechanical alloying. This laboratory ball mill features lubrication free, compact design, safe operation, and easy-to

More

Planetary Ball Mill PM 100 - RETSCH - highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch. ...

More

Stainless Steel Vacuum Ball Mill Jar for Inert Gas

Stainless Steel Vacuum Ball Mill Jar for Inert Gas Grinding in labs. No reviews yet. Zhengzhou TCH Instrument Co., Ltd. 7 yrs CN . Previous slide Next slide. Previous slide Next slide. Other recommendations for your business. Straight

More

Research progress on synthesis mechanism and performance

2024年6月3日 Biochar-iron based material has been recognized as an important soil and underground water remediation material, which successfully achieves by adsorption, reduction, and mediating advanced oxidation.

More

Planetary Micro Milling – PBM - Insmart Systems

Planetary Micro Milling - PBM CE Certified Insmart Planatery Ball Mill (PBM) is ideal for ... Continuous purging of inert gas, while grinding in single bowl system. Special bowl set designed for inert/ special atmosphere grinding – suitable for charging and removal in a glove box.

More

Inert Gas Condensation for Nanoparticle Synthesis

As a class of bottom-up viewpoint in nanoparticle synthesis, inert gas condensation is a perfectly developed and popular nanoparticle synthesis technique owing to its capability and flexibility to control the synthesis process. Briefly, the material is evaporated under the pure helium atmosphere with the helium atoms serving as a cooling agent condensing the atoms to finalize

More

Ball mill - IIT Ropar

Ball mill. CONTACT DETAILS: Student coordinator: Avneesh Kumar, Vinay Gidla. Email: [email protected], gidla ... the grinding can be performed dry, in suspension, or in inert gas. In addition to comminution, planetary mills for mixing and homogenizing emulsions and pastes or for mechanical activation and alloying in materials research ...

More

Ball mill - Wikipedia

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, ... The grinding chamber can also be filled with an inert shield gas that does not react with the material being ground, ...

More

Planetary Ball Mills LMS Technologies Singapore

Fritsch Planetary Ball Mills are designed for versatility and safety. Choose between dry, suspension, or inert gas grinding to suit your specific needs. From mechanical alloying to materials research, these mills provide precise control and exceptional results.

More

Glove-box Planetary Ball Mill (GBM-02) - MicroNano Tools

General Introduction. The GBM-02 planetary ball mill is designed for using in a standard glove box filled with inert gas such as Argon. It can be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small sample preparing, new product development, and small volume high-tech material production.

More

Direct Mechanocatalysis: Using Milling Balls as

2020年4月21日 Besides the mill geometries there exist several easy to control and reasonably well-understood parameters unique to mechanochemical reactions. As mentioned above, the rotational speed (planetary ball mill) or

More

Planetary Ball Mill Lubrication, Inert gas Vacuum,

Planetary ball mill is designed for fine grinding materials down to nano range. It is also used for mixing, homogenizing, ... Planetary Ball Mill 4x100ml with Touch Screen Lubrication Free, Inert gas Vacuum Milling Capable. $4,280.00.

More

Inert Gas Purification System

Lab Rapid Ball Mill. Lab Glove Box / Operation Box. Centrifuge Series. Vibrating Screen Series. CONTACT. Tel: 0086-731-84939972. Fax: 0086-731-84939973. Mobile: 0086-13357214760. Email1: mills@lab-mills. ... The restoring

More

Inert Balls - Baan Machines

The main role of inert ceramic balls is to increase the distribution spot of gas or ... From our Chinese partner we offer e.g. the following range of bed support media: Inert ceramic ball (BSM-100), Ceramic ball shaped pineapple (BSM-200), Ceramic ball with holes ... Steel Ball Mills 20 – 100 litres; Wet Ball Mill 100 – 20000 litres; Ball ...

More

Inert Gas Condensation and Pyrolysis Methods in the Synthesis

This article mainly discusses two of the methods used for the preparation of the nanoparticles and nanocomposite particles. Inert Gas Condensation involves the vaporization of the metal or inorganic materials from a vaporizing source in the presence of an inert gas atmosphere followed by rapid condensation of the vaporized atoms of the metal or inorganic material on a cold

More

Influence of Milling Atmosphere on the High-Energy Ball-Milling

was initially flooded and continuously rinsed during milling. To control the gas flow, a bubble counter was used. Nitrogen and argon were used as inert gases in addition to air. The high-energy ball milling was carried out with a Simoloyer CM08 mill (Zoz) with steel equipment. The milling parameters used in all experiments are listed in Tab. 1.

More

Development of a High-Energy Mill for Powder Metallurgy

tional ball mills. The rotating speed control was done using a variable-frequency drive. The walls of the grinding chamber are hollow and have two connections for water, one for input and one for output to do the drum cooling. The chamber also has two connections for input and output of inert gas. The inert at-mosphere chosen was argon.

More

Selection of an Inert Gas System for the Transportation of

2021年11月16日 Selection of an Inert Gas System for the Transportation of Direct Reduced Iron. ... year in the delta region of Nigeria and it is necessary to be. ... (DRI) during the ball-mill. operation.

More

Preparation of Graphene Nanoplatelets by Thermal Shock

2019年4月28日 The exfoliation of EG to Gnps is further demonstrated with the increase of specific surface area by BET result that is shown in Figure 4 and Table 1.The similarity of nitrogen adsorption/desorption curves shows the unchanged structure between EG and Gnps samples (Figure 4).The data in Table 1 show that the EG sample obtained by thermal shock has a BET

More

(PDF) MPS mills for coal grinding - ResearchGate

2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on ...

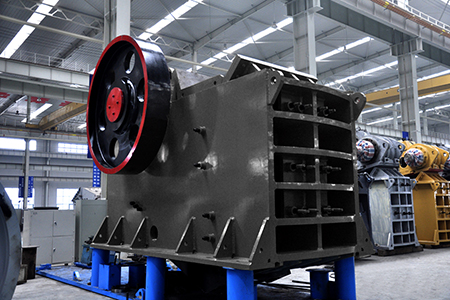

More- ce qui correspond à l'alimentation du broyeur à machoires

- baoshan rouleau quatre rouleau concasseur

- plus grands concasseurs à mâchoires

- chargeur de ceinture de concasseur

- composition de barre de soufflage de concasseur

- concasseur mobile de roche de feldspath à vendre

- drake 16 broyeur déchiqueteur à marteaux

- équipement de moulin au nigeria

- chaux broyeur de pierres a vendre en australie

- detail de broyeur cru classificateur

- Concasseur à machoires Sjjqzx

- quipement minerai de chine broyeur de pierre 200tp

- questionnaire de carriere de marbre

- judul concasseur batu gamping pada teknik pertambangan

- prix concasseurs de pierres et carrières