gypsum size feeding to rotary kiln

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

The FEECO Rotary Kiln Handbook - FEECO International Inc.

A rotary kiln is comprised of a rotating cylinder (called the drum), sized speciically to meet the temperature and retention time requirements of the material to be

More

Rotary kiln process: An overview of physical mechanisms, models

2023年2月25日 The rotary kiln is used in many solid processes, including drying, incineration, heating, cooling, humidification, calcination and reduction. This widespread application can be

More

Energy and exergy analysis of a rotary kiln used for ... - ScienceDirect

2014年6月1日 This paper presents, the energy and exergy analysis of a rotary kiln used for plaster production was performed. Some parameters, such as losses, irreversibility and design

More

Rotary Kiln. Calcination kiln. Drying kiln. - Gypsum

Rotary kilns, for gypsum calcination, are similar to cement kilns, but the main difference is that gypsum kilns are counter-flow compared to cement kilns. In gypsum kilns, the gypsum encounters a temperature of 600-650 °C when it

More

Rotary kiln process: An overview of physical mechanisms, models

2023年2月25日 This article presents the key stages in the modeling of rotary kilns. First, the parameters characterizing the transport of the solid load are presented in detail. The second

More

Rotary kiln - Wikipedia

A well-engineered kiln, when the power is cut off, will swing pendulum-like many times before coming to rest. The mass of a typical 6 m × 60 m (20 ft × 197 ft) kiln, including refractories and

More

Modelling and optimization of a rotary kiln direct reduction process

Rotary kilns (Figure 1) are used for a range of mineral processing operations. Kilns range in size from 2–6 m in diameter and can be 50–225 m long with an operating mass of up to 3000 t.

More

Changes in traditional building materials: the case of gypsum in ...

2021年9月30日 Rotary kiln only permitted the use of gypsum rock pieces of up to 35 mm, which had to be sieved prior to loading.

More

m/sbm gypsum size feeding to rotary kiln crusher company

Write better code with AI Code review. Manage code changes

More

Gypsum Rotary Kiln - Henan Turui Machinery Co., Ltd.

Gypsum rotary kiln is mainly compose of driving device, supporting roller, catching roller, cylinder, ... the raw material is fed into the kiln from the feeding pipe on the upper part of the kiln tail. ... The particle size of raw materials is

More

Gypsum Rotary Kiln Gypsum Kiln Rotary Kiln

Gypsum rotary kiln is used for gypsum calcination. ... Kiln body size ... The tertiary air duct tilt to one side and the materials enter the furnace from two feeding ports. The decomposed materials are collected by a five-stage

More

Facing Rotary Kiln Challenges? 4 Solutions to Help You!

2024年5月30日 Solution II: Easily prevent kiln ring formation Ensuring normal rotary kiln flame is one challenge; another is material looping. This occurs when furnace charge adheres in a ring shape to the inner wall of the high-temperature zone. Minor adhesion is termed kiln skin, while thicker adhesion affecting furnace operation is called ring formation.

More

sbm gypsum feeding in ball mill design.md

Contribute to sili2023/sbm development by creating an account on GitHub.

More

STUCCO PRODUCTION WITH ROTARY KILNS - Grenzebach

Rotary kilns used for stucco plaster calcining are not brick-lined but are fitted with special durable steel inserts. They distribute the feed of gypsum rock uniformly over the cross-section of the kiln. The rock is thus rearranged several times during each rotation of the kiln. At the same time it moves along the kiln in the same direction as the

More

Gypsum Rotary Kiln

The equipment is widely used in the fields of gypsum, fly ash, slag, food, etc. Compared with the rotary kiln whose heat source is coal-fired (which requires a large blast and phoenix system, consumes a lot of electricity, causes great environmental pollution, and increases the cost of coal burning and flue gas post-treatment), the steam rotary ...

More

gypsum shaft kiln

gypsum vertical shaft kiln. Cement Vertical Gypsum grinding mill equipmentshaft kiln vertical cement manufacturing process components of a cement plant from quarry to kiln to cement mill gypsum size feeding Vertical shaft kiln cement or -gypsum vertical shaft kiln-,Optimised vertical-shaft kiln for producing sulfoaluminous Specialists from all parts of the globe use this

More

Gypsum Rotary Kiln-Calcining Equipment-Henan Hongke Heavy

Introduction of Gypsum rotary kiln. Gypsum rotary kiln is an industrial equipment, which can make a lot of production. And the production of gypsum has a great role, mainly used for construction of building engineering, pharmacological treatment, mold processing, chemical industry, cement regulation in many areas, almost became the indispensable in people's daily

More

Rotary Kiln Bauxite Used To Bulid Bauxite Rotary Kiln Factory

Bauxite rotary kiln’s kiln mouse guard and kiln tail feeding spoon use individual cast, which has high heat resistance, corrosion resistance, and wear resistance. The cold wind set in the kiln head transfers cooling air, which can evenly cool down

More

China Gypsum Rotary Kiln Manufacturers Suppliers

gypsum rotary kiln manufacturers, suppliers, ... Feed particle size: 63-100mm . Applications . Application fields: construction engineering, ... During the operation of the rotary kiln, raw meal powder is fed into the kiln shell from the feeding

More

Dynamic modeling of the heat transfer process in

2021年1月1日 This work proposes a mathematical modeling and numerical simulation of a gypsum rotary kiln with indirect oil heating in a three-dimensional transient regime.

More

Cement Rotary Kiln For Sale Rotary Kiln

Performance: advanced pre-heating system of the dry-process cement rotary kiln increase the kiln speed and the output per unit volume, make sure the high clinker quality.; Fuel: wider choice of fuel, include solid fuel, gaseous fuel,

More

JURNAL TEKNIK ITS Vol. 12, No.3, (2023) ISSN: 2337-3539 (2301

cost yang diperlukan dalam proses pembakaran di rotary kiln [8]. C. Rotary Kiln Rotary kiln memainkan peran penting dalam hal konsumsi energi dan emisi, karena besarnya jumlah energi panas dan listrik yang diperlukan [9]. Rotary kiln adalah silinder yang panjang dan agak miring yang ditandai dengan bahan tahan api yang tahan terhadap suhu tinggi.

More

EVERYTHING YOU NEED TO KNOW ABOUT THE CHEMISTRY OF KILN

Alkali chlorides tend to remain in the internal kiln cycle for a long time and can lead to heavy coating and ring formation in the upper part of the rotary kiln and the lower stages of the preheatcr. Chlorides, even in such small quantities as 0.02% in the kiln feed can become so troublesome on some preheater kilns that they are forced to operate with a bypass of up to

More

Burning alternative fuels in cement kilns - Cement Lime Gypsum

In addition, however, the feeding of secondary fuel in the inlet chamber of the rotary kiln has been established as this provides a good option to feed complete rubber tires and also allows to control the oxygen content of the gas in the riser duct, which is a prerequisite for efficient NOx reduction in the calciner.

More

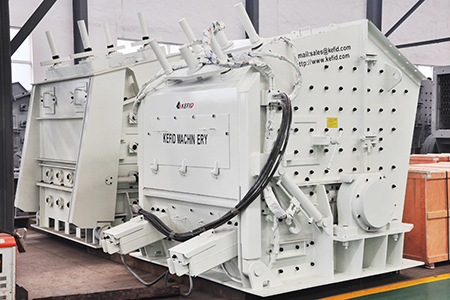

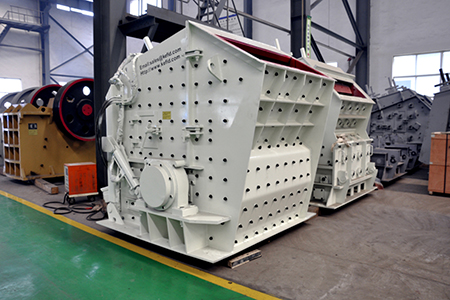

gypsum size feeding to rotary kiln

AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

More

CFD modelling of meat and bone meal combustion in a cement rotary kiln

2015年2月17日 The negative effects of burning a higher amount of MBM in the cement rotary kiln were further demonstrated through a full-scale cement kiln test by the current authors (Ariyaratne et al., 2010). It was found that the free lime content (uncombined CaO) of the clinker is increased when the MBM feeding rates are high in the rotary kiln burner (Fig ...

More

An industrial-scale cement rotary kiln CFD model to characterise ...

investigate the co-combustion of different fuels in cement rotary kiln [1-8]. One study [1] found that annulus fuel feeding results in faster devolatilization and char combustion than central tube fuel feeding. Another study [2] aimed to reduce CO2 emissions by optimizing the combustion

More

Kiln Feeding - Cement Plant Optimization

Kiln Feeding. Kiln, considered as heart of the cement plant needs to be fed with consistent raw meal at uniform feed rate. ... Rotary Feeder: A rotary feeder passing kiln feed to a chute connected to preheater is installed to avoid cold air leakages into the preheater tower.

More>> Next: Machine De Traitement Du Cuivre En Algérie

- broyeurs autogènes et semiautogènes

- fabricant dunite hydraulique de moulin a charbon

- sensation mousse dans oreille

- utilise concasseurs suivis

- broyage concasseurs cne machines

- britador pedra para fabricar areia

- broyeur à charbon usagé à louer en indonésie

- maquinas de mineracão e equipamentos de controle

- des minerais de diamants en Inderecyclage du bentonite

- prix de la nouvelle marque de c100 nordber concasseur a mâchoires

- rouleau broyeur vertical de ciment broyeur vertical

- représentation du tapis roulant

- processing gold crush plant

- extraction et traitement du cadmium

- k type thermocouple probes egt exhaust gas temperature pyro