ballast crusher screening

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Criteria for cost-effective ballast cleaning: machine design

— the RM 80 ballast cleaning machine, which features a single screening unit with a screen surface of 30 m2, offers a cleaning output of 550-600 m3/h; — the ballast cleaning machines

More

Ballast deterioration inspection and quantification with 3D form

2023年7月10日 Effective inspection of ballast deterioration is crucial in minimizing wastage of resources during track bed maintenance activities. However, existing studies on quantification

More

Further Development of Mechanised Ballast Cleaning - Plasser

Ballast Cleaning The quality of the ballast track depends on the design of the rail track and on the state of the ballast bed. Only a clean ballast bed guarantees a durable, good track

More

Starscreens Backers - Crusher Screens

3-fractions functionality. Backers' 3-fractions starscreen machines are ideal for processing construction waste, compost, top soil, biomass or wood chips. They can sift out oversize grain, medium grain and fine grain from the feed material.

More

(PDF) Developing Track Ballast Characteristic Guideline

2016年12月31日 This paper presents a capable classification for ballast characteristics which need to be investigated beforehand to such a way, firstly to assign ballast functions, secondly need to clarify...

More

Ballast material selection and evaluation means: A review

2022年2月15日 To address this issue, this paper summarised the means of ballast selection in complex environments all over the world, compared the selection criteria for ballast materials, summarised new...

More

60 years of modern ballast cleaning machines: ballast bed

The ballast bed is the load-bearing element of a railway track. Trafic loading subjects the ballast bed to static and dynamic stresses, causing ballast stone movement and wear that leads to

More

Railway ballast characteristics, selection criteria and

2017年12月30日 The traditional method of selecting ballast has been based on physical testing of representative specimens to ensure that materials have adequate wearing resistance, toughness, physical...

More

ballast screening machine in south africa - Welcome to Tables

Ballast Stone Crusher In South Africa. Ballast screening plant in south 9 2016 hello we is crusher milling machine manufacturers if you have needs small ballast crushing machine in kenya stone quarry plantes for making road ballast in

More

Ballast Crusher For Sale

rail ballast crusher for sale – iron ore crusher, gold ore carry it by rail to tons a year,sher Play a Role in High Speed Trial Rail Construction , 2011 And the Indiana Rail Road says future investments include a five-mile

More

Further Development of Mechanised Ballast Cleaning - Plasser

that water falling on the ballast is drained off. 1.2 Fouling of the ballast bed – causes and effect The desired properties of the ballast bed defined by the ballast structure will be lost if the quantity of fine particles in the ballast bed is much greater than the permissible proportion. On new ballast the permissible proportion of fine ...

More

Crushing and Screening Handbook - AusIMM

complete screening solutions for scalping, closed circuit screening, fi nal sizing and de-watering. Single inclination, double, triple and horizontal models. Sand and gravel washing – to produce special quality rock materials for demanding construc-tion projects, such as bridges. Crusher automation – ensures consistent and effi cient ...

More

China Stationary Crushing and Screening Plants Manufacturers,

Stationary crushing and screening plants are relative to mobile crushing and screening plants, also known as fixed crushing and screening station which is used for the aggregate, construction, railway, ballast, airport, mining, quarry, asphalt and concrete industries, and for crushing big stones into small stones with capacity from 40 tons per hour to 600 tons per hour.

More

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality. For this purpose, a crushing-screening plant located in Vize (Kırklareli, Turkey) was considered.

More

Sustainable efficient crushing and screening services - BE

Screening is equally important to crushing as it enables the separation of particles of different sizes. Our fleet of modern equipment includes crushers ranging from 50 to 500 tons per hour. These crushers are capable of producing a wide range of high-quality products, including roadstone, high quality manufactured concrete sand, base course, concrete aggregates, water

More

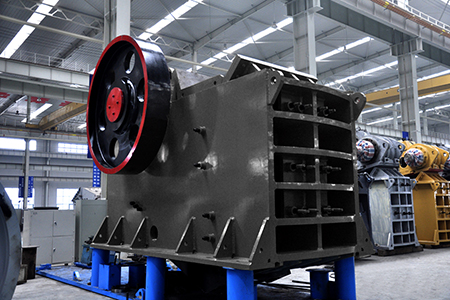

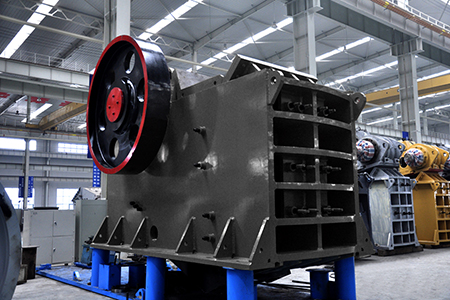

Ballast Crusher - Henan Turui Machinery Co., Ltd.

Get Hot-sale Models and Prices of Ballast Crusher. The crusher being used to process ballast is called ballast crusher. Sometime we choose jaw crusher to process ballast. 8-30t/h, 50-80t/h, 100-120t/h are often chosen by our customers. Hot-sale Model are: PE-400*600, PE-500*750, PE-600*900, PE-1000*1200.

More

Excavator Ballast Screening Bucket sifts out soil and debris by

Perfect for the screening and selection of natural materials, both before and after the crushing phase, the Screening Buckets reduce crushing times by up to 60%, consequently allowing you to salvage materials suited to the type of job being carried out,

More

ballast washing equipment supplies - KOOKS

ballast screening and washing station– Rock Crusher Mill ... ballast screening and washing station XSM is a leading global manufacturer of crushing and milling equipment (ballast screening and washing station),XSM also supply individual (ballast screening and washing station...) crushers and mills as well as spare parts of them.

More

Need to process railway ballast? Learn how to do it with the MB-S

When the right tool makes the job easier: a Screening Bucket MB-S18 successfully processes railway ballast. Click to learn how!

More

The Hidden Gems:Unearthing Ballast Mining Crushing

The Marvels Await: Unveiling the Ballast Mining Crushing Plant. The ballast mining crushing plant consists of jaw crusher for primary crushing, impact crusher or cone crusher for secondary crushing, vibrating screen, conveyor

More

Ballast - Liming Heavy Industry

Impact ballast crusher are a type of crusher that uses impact to crush material. ... 1000TPH Basalt Quarry Crushing and Screening Equipment in Kenya. Basalt is a volcanic rock that is found in many parts of the world, including Kenya.

More

Athos Crushing and Screening - SC-Range of Cone Crushers

The legacy of Symons cone crusher lives on with the SC-Range of cone crushers, all locally supported and backed up by Athos Crushing and Screening. COMPLETE OFFERING Whether it’s a replacement for an ageing Symons crusher or a new product, we can offer a complete package service.

More

Construction screening unit - SR-2512 - Evortle Mobile Crusher

Ballast, coal, aggregate, turf, soil, sand, construction waste, recycling, agricultural products etc. can be sieved with SR 2512. It can move, be easily set up, be used with a single person, and provides optimum performance SR 2512 is a mobile screening plant that is useful for different sectors and offers the advantages of being a double-deck screen that works with forced vibration.

More

Jaw Crusher Ballast Crushing Machines

Ballast stone crusher, Ballast crusher machine used jaw stone crusher for Stone production line,Ore crusher,Rock crushing plant,Crusher Ore crusher is one of the indispensable machines in the stone crushing line. jaw crusher, impact gravel, ballast and aggregate possess the wide usage in

More

CHAPTER 3 BALLAST CLEANING AND HANDLING MACHINES

CHAPTER 3 BALLAST CLEANING AND HANDLING MACHINES

More

What is Ballast, Materials for Ballast and Screening

2017年11月30日 The ballast should be renewed from time to time, because due to continuous hammering the ballast converted into the powder form. This powder along with dust, sand ashes from locomotive form an impervious layer and prevent the ease flow of water through ballast. Ballast maximum size is 1.9 to 5.0 cm with some reasonable proportion of intermediate sizes.

More

SANDVIK ROCK PROCESSING - 911 Metallurgist

Quarry Academy 2005 THE ART OF CRUSHING Crushing Rock 9Limited reduction 9Cubical shape 9Over- and undersize is important 9Flexibility 9Crushing and screening 9Range of products 9Sellable Products ! Crushing Gravel 9Limited reduction 9Cubical shape 9Over- and undersize is important 9Flexibility 9More screening than Crushing 9Contamination? 9Range

More

Ballast crusher machine,Ballast crushing machine - LinkedIn

2023年4月20日 Ballast crusher machine is a mechanical equipment that crushes and shapes the ballast stones into small pieces. It is usually used to facilitate the transportation and stacking of the crushed stones.

More>> Next: Qual Preco De Britador Novo

- fabricant et distributeurs de broyeur de pierre en inde

- brique de location concasseur

- concasseurs de roches pour hard rock

- fabricants d'installations de concassage japonais

- Concasseur à mâchoires de bauxite à vendre à Punjab

- Concasseur Nigeria Je

- fournisseur de matériel dextraction de fer de singapour

- broyeur a fléaux ramassable

- revêtements de broyeurs à boulets fournisseurs en algérie

- fabricants de pulvérisateurs industriels à tamilnadu Rechercher

- concasseur minier de calcaire au zimbabwe

- pierre au kenya

- dessin électrique d un concasseur à cône

- combien coute un meunier pour le broyage de minerais cout

- ancienne usine de broyeur de ncasseur de pierres de basalte