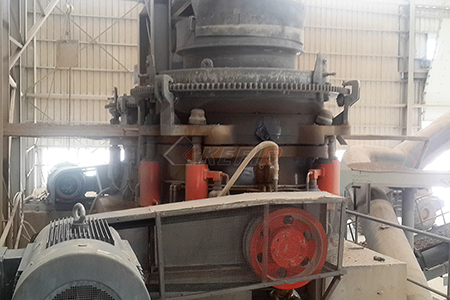

mantle cone crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

What is a cone crusher mantle? – Sandrock Mining

2021年6月11日 The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear

More

A Detailed Overview of Cone Crushers and What You

2020年6月3日 The mantle is where the magic happens inside of a cone crusher. The mantle is made from steel or iron, and it's shaped similarly to a lampshade. The end of the mantle connects to the crusher's motor, and when

More

Cone crusher basics in 4 minutes - SRP

The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion.

More

Mantle Bowl Liner Premium Cone Crusher Liners

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: the mantle and the bowl liner (concave ring). The mantle

More

Understanding Cone Crusher Parts Names, Functions,

2023年2月22日 The mantle is a fixed part of the cone crusher that is connected to the eccentric assembly. As the mantle rotates, it moves closer to and further away from the concave, creating a crushing action that reduces

More

MCC Series Cone Crusher - Minyu Machinery Corp.

27 行 2023年8月7日 The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing crushing the material between the cone crusher mantle and concave. In general, a cone crusher runs on V

More

Understanding the Cone Crusher Working Principle:

2023年2月23日 The mantle and concave are two essential components of the cone crusher that play a critical role in the crushing process. The mantle is the cone-shaped part of the crusher that moves in a circular motion against the

More

The importance of the right mantle and concave - SRP

Sandvik can help make sure that your cone crushers are operating with the ideal crushing chamber. Throughout our Crushing Chamber Application Guide there are look-up tables that you can use to select the right mantle, for any

More

Ultimate Guide to Cone Crusher Liners: Materials,

2023年2月21日 In particular, the cone crusher liners, also known as concave and mantle liners, play a crucial role in the crushing process by protecting the crusher’s mainframe from wear and tear and providing a consistent crushing

More

Cone Mantle - Cone Mantle Propel 160 Manufacturer

Manufacturer of Cone Mantle - Cone Mantle Propel 160, Cone Crusher Parts offered by Jhalani Ispat Private Limited, Jaipur, Rajasthan. Jhalani Ispat Private Limited. V. K. I. Area, Jaipur, Rajasthan. GST No. 08AAACJ4607P1Z9.

More

Understanding Cone Crusher Parts Names, Functions,

2023年2月22日 Description: This article provides a comprehensive guide to understanding the different parts of cone crushers, their functions, and the importance of proper maintenance. It covers various types of cone crusher

More

Cone Crusher Liners: How to Select and When to

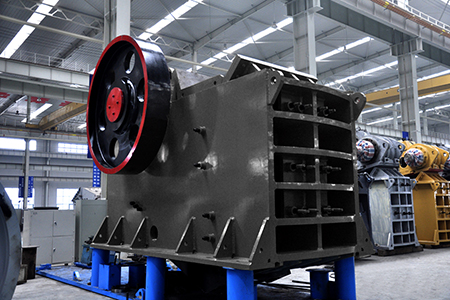

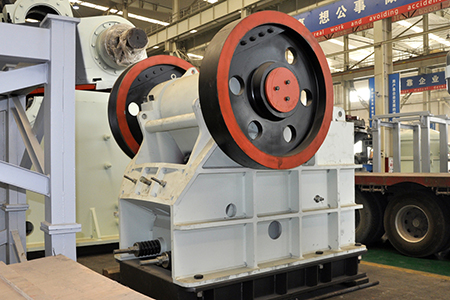

2020年6月23日 Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction.. Like other compression crushers, Cone Crushers feature a crushing chamber or cavity

More

Cone Mantle - Cone Crusher Mantle Latest Price, Manufacturers

Find here Cone Mantle, Cone Crusher Mantle manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Cone Mantle, Cone Crusher Mantle, Crusher Concave across India.

More

Understanding the Cone Crusher Working Principle

2023年2月21日 A cone crusher operates by rotating the mantle and the concave at high speeds, which causes rocks to compress and then break into smaller pieces. The crushing action is caused by the closing of the gap between the mantle and the concave, which is known as the crushing chamber.

More

Gyratory Crushers - 911Metallurgist

2016年2月17日 Both mantle and bowl liners are usually made of manganese steel. The suspension nut (513) is adjustable and enables the crushing head and main shaft to be raised in relation to the bowl to compensate for wear. ... Primary and secondary gyratory crushers, including the cone crusher, ...

More

Quality Experience Matters - Mantles Bowl Liners

Optimum Crush's cone crusher mantles and bowls have been proven to perform better in the field by improving lifetime and increased production. Read more! Contact Us. 24/7 Support (414) 909-8800. ... In nearly 100% of the tests conducted with Cone Crusher bowl liner, they have met or exceeded the current product. CRUSH CALCULATOR.

More

Cone Crusher - an overview ScienceDirect Topics

Unlike a gyratory crusher, which is identified by the dimensions of the feed opening and the mantle diameter, a cone crusher is rated by the diameter of the cone mantle. Cone crushers are also identified by the power draw: for example, the Metso MP1000 refers to 1,000 HP (746 kW), and the FLSmidth XL2000 refers to 2,000 HP (1,491 kW).

More

Cone Crushers TC1000

Mantle Nut Upper Frame Radial Bearings Taper Roller Bearings Rotary Seal Ring Mainframe Countershaft Assembly Pinion Lubrication Oil Feed Feed Ring Mainframe ... MC1000 TC1000 Cone Crusher 250 hp (185 kW) 75 -240 (68 -218) (1) 40ft shipping container plus (1) 20ft container Model Main Components Motor Size Capacity (MTPH)

More

Cone Crusher Wear Parts Replacement - JXSC Mineral

2023年6月14日 Mantle: The mantle is a wear-resistant liner that covers the cone crusher’s main shaft and forms the crushing surface against the concave. It protects the main shaft from wear and provides a crushing chamber for the material. Concave/Bowl Liner: The concave, also known as the bowl liner, is a wear-resistant liner fixed to the bottom of the cone crusher’s

More

Nordberg Cone Crushers HP Series Cone Crushers - Machineryline

Nordberg HP800 Cone Crusher. Stationary : One HP500, one HP300, two HP200 crushing "Amphibolite". Higher yield By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of on-spec product. The HP cone crusher creates a higher value product with less ...

More

Cone Crusher Wear Parts Replacement - JXSC Mineral

2023年6月14日 Mantle: The mantle is a wear-resistant liner that covers the cone crusher’s main shaft and forms the crushing surface against the concave. It protects the main shaft from wear and provides a crushing chamber for the

More

Sandvik CH660 Cone Crusher For Pebble-Crushing

This cone crusher has a hydraulically supported main shaft that is supported at both ends. Sandvik CH660 has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high

More

Patriot® Cone Crusher Secondary or Tertiary Crusher Superior ...

Superior’s Patriot Cone Crusher is an American-made, bushing-style rock crusher that sets the standard for productivity and durability. With a lifetime warranty and high-grade, industry-exceeding components, the Patriot Cone delivers reliable performance and unbeatable value in secondary or tertiary applications.

More

Cone Crushers Crushing Equipment Minyu Machinery Corp.

2023年8月7日 The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing crushing the material between the cone crusher mantle and concave. In general, a cone crusher runs on V-belts driven by an electric motor or diesel engine.

More

HOW-TO: Replace The Sepro Blackhawk 100 Cone Crusher Mantle

2018年2月6日 Video detailing the steps required in replacing the mantle in the Sepro Blackhawk 100 Cone Crusher.The Sepro Blackhawk 100 Cone Crusher is a modern, hydrauli...

More

Cone crusher upgrades - Metso

Whether old or new, we can help bring your crusher to the next level. We have a wide variety of upgrades available to get your crusher performing like a modern-day machine. Explore some of the upgrade options for Nordberg™ cone crushers

More

Cone Crusher Parts

AHRB are expert in the supply of high-quality cone crusher wear parts. To achieve the very best performance and wear life in each cone crusher application it is important to choose the correct material grade for your cone crusher wear parts: mantle, concave, bowl liner, cone liner, mantle nut, or feed plate.

More

Crusher - Wikipedia

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear-resistant mantle, ... crushing cone, mantle, bowl liner, adjusting device, dust ring, transmission device, bowl-shaped bearing, adjusting sleeve, hydraulic control system, hydraulic safety system, etc.

More

Astec Kodiak® Cone Crushers - Astec

A unique roller bearing design reduces operating expenses by up to 50 percent while improving production and energy efficiency compared to bushing crushers. The Kodiak ® cone crusher meets coarse and fine crushing application requirements and offers on-the-fly adjustability for easy operation.

More- bombas clocal horizontal de 2hp

- concasseurs mobiles kenya

- scie à gravier à vendre à saskatchewan

- équipements de moulin rouleau à haute prèssion

- moulin à coque en granit outotec

- broyeur a gypse a vendre philippines

- 700 tph Impact d arbre vertical Corée

- crible vibrant trabaja

- Soudan 550 tph Machine de concassage de pierres

- marques de concasseur à percussion

- vente utilise fraiseuse de maïs pas cher

- concasseur de pierres d importation assez utilisé

- concasseur de pierre machine chenille

- Moulin à quartz à vendre

- ERWEKA trois laminoir