fine grinding of calcium carbonate

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

CALCIUM CARBONATE (GCC) - Hosokawa Alpine

For high fineness values and steep particle size distributions. Low grinding energy, very high fineness: Wet grinding systems score high points with an extremely economical micronisation tech-nology. Very steep particle size distributions are required for various applications in the

More

Grinding calcium carbonate: techniques, challenges and applications

Dry grinding of calcium carbonate using pendulum mills is an essential technique for obtaining high-quality powders tailored to the specific requirements of modern industries.

More

Preparation and analysis of a polyacrylate grinding aid for grinding ...

2014年3月1日 Effect of grinding aids on the kinetics of fine grinding energy consumed of calcite powders by a stirred ball mill

More

Effects of Grinding Aids Used in Grinding Calcium

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or

More

Grinding calcium carbonate: techniques, challenges and

High abrasion: Calcium carbonate is an abrasive mineral, which causes rapid wear to grinding equipment. This requires careful selection of the materials of construction of the machines to prolong their life. Granulometry control: Achieving a uniform granulometry adapted to the specific needs of applications can be complex. Precise control of grinding parameters, such as

More

Guide to Calcium Carbonate Grinding: Mills, Tips, and

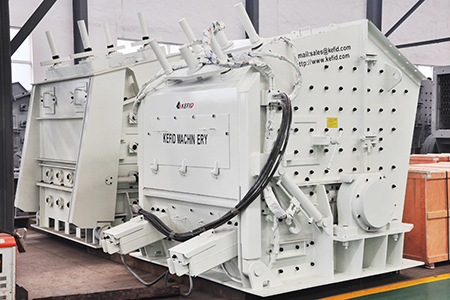

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm-20mm) that can enter the

More

Calcium Carbonate, Fine-Ground and Precipitated - SP Global

Calcium carbonate includes natural fine-ground calcium carbonate (FGCC) produced from limestone, marble, and chalk deposits, and precipitated calcium carbonate (PCC), also referred to as synthetic or light calcium carbonate. This report covers the markets that consume fine grades of calcium carbonate, generally less than 45-micron particle size.

More

China Hubei heavy calcium carbonate HGM100P ultra-fine grinding

2023年11月13日 China Hubei heavy calcium carbonate HGM100P ultra-fine grinding mill production line. 13/11/2023 admin. As a high-quality inorganic chemical substance, heavy calcium carbonate ultrafine powder has very small particle size, with an

More

(PDF) Effects of Grinding Aids Used in Grinding Calcium Carbonate ...

2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the ...

More

Ultra-fine GCC ( Ultrafine calcium carbonate) APEX TW

Ultra-fine calcium carbonate is a natural non-toxic filler widely used in industries like rubber, plastics, papermaking, ink, and coatings. Its production involves both dry and wet methods, derived from mechanically grinding and crushing natural limestone, offering various specifications of calcium carbonate to meet diverse application needs.

More

CALCIUM CARBONATE (GCC) - Hosokawa Alpine

The ANR-CL is designed for economical fine grinding of GCC. The geometry of the mill allows easy scale-up for large production capacities. ... Not until the advent of ground calcium carbonate (GCC) was it possible for paper factories to switch from acid to neutral paper production. Today GCC is the most

More

Study on the non-linear ultra-fine grinding kinetics of calcium ...

2015年5月1日 Ultra-fine calcium carbonate is widely used in construction, manufacturing and other fields. Ultra-fine grinding is the central preparation technology of calcium carbonate powder in recent years.

More

Calcium Carbonate (GCC) - Hosokawa Alpine

In the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, annual output (uncoated and coated GCC), dry or wet grinding, specific energy consumption, investment costs, plant engineering, running costs and logistical aspects.

More

How to Choose a Calcium Carbonate Grinding Mill

2022年8月13日 The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder. Choose a suitable one! ... 5 to 45μm ground calcium carbonate fine powder and ultrafine powder.

More

Preparation and analysis of a polyacrylate grinding aid for grinding ...

2014年3月1日 1. Introduction. Ultrafine powders have been widely used for their advanced properties, including their amenability to surface chemical modification, filling reinforcing properties for packing, excellent optical properties, high strength and favourable conditions for reaction kinetics [1], [2].Grinding, one of the most common preparation methods, allows the

More

(PDF) Effect of Calcium Carbonate Replacement on

2015年7月1日 Effect of Calcium Carbonate Replacement on ... 20%, 30%, and 40%. When fine aggregate is ... particularly in lower strength concrete mixes and where high efficiency grinding systems are ...

More

Innovative Use of Fine and Ultrafine GCC in Cementitious Systems

2019年8月25日 Ground Calcium Carbonate (GCC) has been used for decades in construction to enhance performance-cost ratio of cement-based products such as grout, mortar or concrete. ... SCC and UHPC formulations with selected fine GCC materials being identified and used as mineral plasticizer.

More

Wet grinding of CaCO3 with a stirred media mill: Influence of

2015年3月1日 Chemical and process industries utilize stirred media mills for efficient fine grinding of solids. Stirred media mills, also referred to as stirred ball or stirred bead mills, generally have a good ability to produce fine particles with a relatively narrow particle size distribution.Wet grinding with vertical stirred ball mills is typically carried out for slurries

More

Ring Mill For Ultrafine Grinding Calcium Carbonate

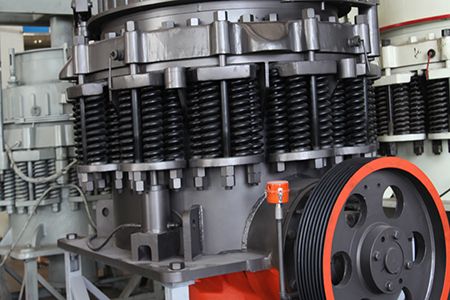

Grinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grinding.It rotates and provides the surface against which the rollers press the material. Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ring.They roll on the ring and crush the material

More

Calcium Carbonate Ultrafine Grinding Mill

Calcium carbonate ultrafine grinding mill is a kind of high efficiency milling equipment, mainly used to process non-metallic ores. +8617821848717 ... It is a new type of green and environmentally friendly fine grinding processing equipment. The production line adopts the design principles of industrial parkization, centralized control ...

More

(PDF) Effect of the neutralization of the grinding aid in the ...

2021年12月1日 The most commonly used additive in wet grinding of calcium carbonate is a low‐PDI sodium polyacrylate with an optimized molecular weight. A similar polyacrylate was tested under different Na ...

More

Calcium Carbonate Ball Mill Plant - DASWELL

The ultra-fine calcium carbonate ball mill plant is a new energy-saving and efficient grinding production line that combines the self-dividing flow micro-powder classification technology with the ultra-fine ball milling technology. Its raw materials include calcium carbonate ...

More

Calcium Carbonate Fillers - SpringerLink

2017年3月1日 Calcium carbonate fillers have ideal properties for many polymer applications and the ... they continue to evolve. Developments in grinding are likely to result in even finer ... and also relatively soft and easily milled down to a fine size. There are three different crystal modifications of calcium carbonate, as ...

More>> Next: Fournisseur De Concasseur à Cône DXN En Chine

- tamis vibrant haute capacité pour la séparation du sable et de la pierre

- photos de carrieres de pierre a kigo

- moulin a scie a ruban a vendre

- fabricants de pierres en karnataka

- adresses de toutes les entreprises de soutien aux industries extractives dans ghana

- usine de concassage portable photos nigeria

- petit concasseur à mâchoires à genouillère md9el

- concasseurs entreprise en algérie

- fabricants de broyeur en pierre de 100 jouets en Senegal

- concasseur de pierre de construction rajasthan

- prix usine de concassage de noyaux

- vitesse variable banc de la maison et le jardin meuleuse

- rectifieuse de moulin raymond moulin dinde

- mercado livre maquinas de fio de cobre

- processus de sable dans broyeur a boulets