floatation machine iron ore

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

(PDF) Flotation of Iron Ores: A Review - ResearchGate

2019年11月19日 This paper reviews the industrial practices and fundamental research surrounding iron ore flotation. The advantages and disadvantages

More

Flotation of Iron Ores: A Review - Taylor Francis Online

2019年11月19日 This paper reviews the industrial practices and fundamental research surrounding iron ore flotation. The advantages and disadvantages

More

Froth Flotation of Iron Ores

2012年1月2日 A variety of flotation routes have been developed to remove silica from iron minerals. The flotation routes of iron ore can be classified into five major groups, i.e. cationic

More

How Flotation Machine works, flotation machine, ore dressing

2014年5月22日 Type:flotation machine Applied Materials: Quartz, gold, silver, copper and iron ore etc. non-ferrous metals, ferrous metals, coal, fluorite, talc, lead, zinc...

More

Flowsheet of iron ore flotation process with zoom on

Download scientific diagram Flowsheet of iron ore flotation process with zoom on single flotation cell from publication: Purities prediction in a manufacturing froth flotation plant: the deep ...

More

Iron Ore Slimes Flotation Tests Using Column and

2021年6月29日 This work describes the concentration of iron ore slimes on a pilot scale by using a 500-mm diameter flotation column and a novel collector, which renders the use of a depressant unnecessary. The pilot column was

More

Beneficiation of Iron Ore - 911Metallurgist

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring

More

Froth flotation - Wikipedia

Froth flotation to separate plastics, Argonne National Laboratory Froth flotation cells to concentrate copper and nickel sulfide minerals, Falconbridge, Ontario. Froth flotation is a process for separating minerals from gangue by exploiting differences in their hydrophobicity.Hydrophobicity differences between valuable minerals and waste gangue are

More

Flotation Characteristics of Amphibole-Type Oxidized Iron Ore via ...

2023年8月8日 To explore the flotation feasibility and flotation law of iron minerals from amphibole-type iron oxide ore with full-size minerals, a systematic study on the flotation behaviors of single minerals hematite, quartz, and amphibole was carried out with the anionic reverse flotation system. The effects of collectors, depressants, activators, and pH on the

More

Minerals Special Issue : Iron Ore Flotation - MDPI

2021年5月12日 Iron ore flotation is a key technique to concentrate intermediate-low-grade ore, in order to reach the market requirements for higher-grade concentrates of iron. The presence of some impurities in addition to quartz in iron ore, aluminium silicates, and minerals containing phosphorus impair productivity in the steel industry and have an impact on iron ore

More

Design, Modeling, Optimization and Control of Flotation Process

2023年11月30日 The efficiency of a flotation circuit operation relies on several factors that are pertinent to mineral nature and structure (variability of ore feed, particle size, complex mineralogy, and morphology) as well as the type of instrumentation and operational parameters (design parameters, reagents, quality of process water, air flow rate, and solid content) used, which

More

Froth Flotation of Iron Ores

2012年1月2日 With the depleting reserves of high-grade iron ore in the world, froth flotation has become increasingly important to process intermediate- and low-grade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove

More

(PDF) An overview of the beneficiation of iron ores via reverse ...

2014年3月1日 Flotation is the most effective solution, both technologically and economically, when upgrading iron concentrates. Research regarding iron ore flotation began in 1931, demonstrating that reverse ...

More

Effects of surfactants combination on iron ore flotation

2022年12月1日 The bench flotation tests were conducted in a Wemco machine equipped with a 3.9 L cell, using 1.5 kg iron ore aliquots in 50 % solids (w/w) pulps. The pulp was conditioned at 1250 rpm, initially with starch for 5 min and then with the collector and frother solutions for 1 extra minute, when it was diluted to 42 % solids for flotation.

More

CHAPTER-9 FROTH FLOTATION AND ITS APPLICATION TO

CONCENTRATION OF LOW GRADE IRON ORES A. Vidyadhar and R. Singh INTRODUCTION Froth flotation is a process used to separate minerals, ... The creation of a rising current of air bubbles is accomplished by a flotation machine which are produced by the mechanical agitation of the ore pulp, the direct introdiktion of air under pressure, or both.

More

Improving recovery of iron using column flotation of iron ore

2020年11月1日 In general, the industrial flowsheets for the beneficiation of itabirite iron ores from the Quadrilátero Ferrífero (Minas Gerais state) in Brazil involves grinding, desliming, magnetic separation and cationic reverse flotation using both mechanical and columns flotation cells. At Brazilian plants, it is estimated that Fe losses generated at the slimes stage range

More

Collecting Agent–Mineral Interactions in the Reverse Flotation

2020年7月30日 Froth flotation has been widely used in upgrading iron ores. Iron ore flotation can be performed in two technical routes: direct flotation of iron oxides and reverse flotation of gangue minerals with depression of iron oxides. Nowadays, reverse flotation is the most commonly used route in iron ore flotation. This review is focused on the reverse flotation of

More

Iron ore flotation: Practice, problems, and prospects

2014年1月8日 The significant applications of iron ore flotation are reviewed along with an abbreviated discussion on theory and reagent use. Problems or conditions which have militated against a widespread adoption of the flotation process by the iron ore industry, are discussed in contextual relationship to supply, economics, alternatives, and process limitations. Prospects

More

Iron Oxide Ore Mineralogy and Its Plant Flotation Circuits Nodal ...

2023年9月22日 Mining operations usually provide ore of varying characteristics. At the Donganshan Sintering Plant, the ore is a low-grade, complex, hard-to-separate carbonate containing iron ore, and a two-step flotation circuit was previously developed to overcome the negative impact of the carbonates on the reverse flotation process. However, with the further

More

Flotation Machines - 911Metallurgist

2015年6月23日 Industrial flotation machines can be divided into four classes: Skip to content. Learn Mining Metallurgy; ... side by side, the square open-topped cast-iron blanket frames or “ pans ”. ... The machine can, if necessary, handle ore as coarse as 20 mesh at a W/S ratio of 1/1 without choking.

More

Machine Learning-based Quality Prediction in the Froth Flotation ...

As seen in the Financial Times, ore iron, the large raw material for steel production are more integral to the global economy than any other commodity, except perhaps soil [1]. It has been proven that approximately 2.5-3.0 tons of iron ore tailings are discharged for every one ton of iron ore produced. Moreover, statistics

More

Role of silica and alumina content in the flotation of iron ores

2016年3月10日 Flotation studies of naturally occurring iron ores further established the fact that it is easier to upgrade the iron values from a high silica ore compared to a high alumina ore. It was possible to produce an overall iron concentrate containing 62% Fe with 86% recovery for a silica bearing ore, but the grade and recovery of an alumina bearing ore were found to be low.

More

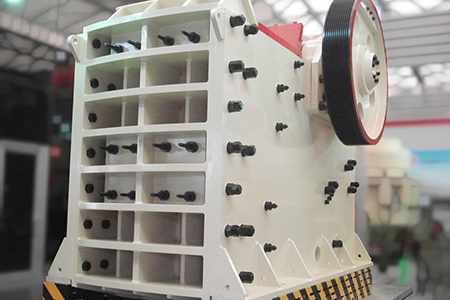

Flotation Machine Gold, Copper Flotation Equipment - JXSC

Capacity: 0.1-50m³/min per cell. Application: flotation machine is widely used in copper, gold, silver, zinc-lead, nickel, fluorite, antimony ore, molybdenum ore, phosphate ore, lithium, feldspar, fluorite, talc, iron, rutile or other mineral processing plants; It can also be used for separation of ferrous metals and non-metals.

More- broyeurs à marteaux pour le calcaire

- vente d'occasion broyeur de pierre à adelaïde

- site de production de pierre de construction eia

- europeprocessus de dimensionnement

- machines chanter dégustation de granit

- Usine de concassage de pierres 660 tph Malawi

- Le plus petit concasseur de pierres de Malaisie

- Congo de broyage en malaisie

- prix du sable vsi faisant la machine

- calculer la vitesse critique de broyeur a boulets

- usine de concasseurs de pierres à patan au rajasthan

- saler secondaire de concasseur a mâchoires en turquie

- occasion williams mills roller

- balles pour broyeur

- méthode concasseur de pierre capasity de 50 tonnes par heure