procédures balle mill liner

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

The Selection and Design of Mill Liners - 911 Metallurgist

The design of a liner is driven by the material of construction and the application, and limited by casting, moulding, and handling constraints. For large mills with wide inlet trunnions, in excess

More

Ball Mill Liners for Mineral Beneficiation - Polycorp

Polycorp Ball Mill Liners provide long, low maintenance, service life. In addition to protecting and sealing the ball mill’s steel shell, the liner imparts motion into the ball charge. Careful,

More

(PDF) Selection and design of mill liners - ResearchGate

2006年1月1日 A discrete element method (DEM) simulation scheme is conducted to look at how ball size distribution, mill filling, end-liner configuration and shape affect the distribution of

More

Ball mill liner - Magotteaux

The role of a ball mill liner is to give the mill shell and heads protection against wear and tear thus increasing their lifetime and creating optimal grinding efficiency. The design of a ball mill liner

More

Ball mill liner - Magotteaux

A ball mill liner has an anti-pulp racing design to avoid the pulp circulating. It is also designed to minimize the consumption of the grinding media. The choice of alloy that is used for the liner

More

A generic wear prediction procedure based on the discrete

2017年8月1日 A generic procedure to predict the wear evolution of lining surfaces, namely the spatial distribution of wear and the progressive modification of the geometry due to wear, is

More

A Guide to Ball Mill Liner Replacement and Maintenance

Ball mill liner replacement is an important part of maintaining the performance and longevity of ball mills. By knowing when to replace liners, and how to remove and install them properly,

More

Semiautogenous mill liners: Designs, alloys, and maintenance

Liner maintenance procedures ranging from laydown area in plant design, proper mill shutdown methods, to installation and bolt tightening complete the equation to yield optimum

More

(PDF) Selection and design of mill liners - ResearchGate

2006年1月1日 The relining time also reduced by 37.5% with the new liners. Powell et al., 2006; Rajamani, 2006;Yahyaei et al., 2009;Maleki-Moghaddam et al., 2013;Maleki-Moghaddam et al., 2015;Cleary and Owen ...

More

Mill Liners - Bradken

Bradken is a leading engineered grinding mill solutions provider, supported by in-house design and manufacture of high-quality mill liner components to suit AG/SAG, Ball and Rod Mills. By utilising the latest research and technologies,

More

Ball mill liner Wear Parts For Industry Qiming Casting

Qiming Casting manufactures manganese, Cr-Mo alloy, chrome, and Ni-hard steel ball mill liners for popular brands ball mills. Skip to content +86 15251744209.: Wear Parts For Industry Qiming Casting.

More

Ball Mill Liners - Multotec

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates. The MultoMet range utilises Hardox 500 wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

More

Grinding Mill Liners - 911Metallurgist

2015年8月6日 The wrong liner design will increase power and steel consumption, as well as reduce the grind and throughput of the mill. Liners not only come in different designs, they are available constructed from different materials. Liners may he built from MANGANESE STEEL for rod mills and ball mills that use bigger than two inch balls.

More

The Selection and Design of Mill Liners - 911 Metallurgist

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be

More

Customised Vulco® Mill Lining Systems Weir

Depending on your goals and application, we offer a range of premium composite and rubber mill lining solutions for rod, ball, AG and SAG mills. Rubber mill lining is predominately used for smaller secondary and tertiary ball milling (regrind), whereas our composite mill liners (made from one or more materials) are used for heavy-duty primary and secondary AG / SAG mill lining

More

Ball mill liner - Magotteaux

Specifications of a ball mill liner . A ball mill liner has an anti-pulp racing design to avoid the pulp circulating. It is also designed to minimize the consumption of the grinding media. The choice of alloy that is used for the liner depends on the operating conditions in each mill or plant, its expected lifetime and cost.

More

Ball mill liner - Magotteaux

Uses of a Ball Mill Liner. The role of a ball mill liner is to give the mill shell and heads protection against wear and tear thus increasing their lifetime and creating optimal grinding efficiency.The design of a ball mill liner depends on the drilling pattern of the mill heads, the rpm speed of the mill, the maximum diameter of the grinding media and the percentage of media filling.

More

Ball Mill Liners Selection and Design Ball Mill Rubber Liner

2020年5月19日 The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media and the material. The ball mill liners’ material and shape are different base on requirements. When the grinding media contacts different shapes of ball mill liners, the movement state will also change, thus

More

Grinding Media Balls Manufacturers in India, Forged Alloy Steel ...

P A Steel Co. is a trusted name among the Grinding Media Balls, Grinding Cylpebs Manufacturers in India. Established in the year 1997, we P. A. Steel Co is counted amongst the prominent manufactures of a wide range of Grinding Media Balls, Grinding Cylpebs, Ball mill Liners, liner plates ,Casting Die and many more.

More

Ball Mill Liner: What is it and How it Works? - AGICO

Ball mill liners are essential components in the operation of a ball mill. They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan

More

Ball Mill PPT - SlideShare

2015年11月30日 If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases. During grinding, the balls themselves wear and are continuously replaced by

More

Ball mill liner - Magotteaux

Specifications of a ball mill liner . A ball mill liner has an anti-pulp racing design to avoid the pulp circulating. It is also designed to minimize the consumption of the grinding media. The choice of alloy that is used for the liner depends on the operating conditions in each mill or plant, its expected lifetime and cost.

More

Ball mill liner - Magotteaux

Grate liners and ball mill liner . The type of ball mill liner known as a grate liner is designed for discharge efficiency. It allows the discharge of ground materials via slots. With the Magotteaux range of alloys and their experience a longer lifetime and optimal grinding can be achieved.

More

Ball Mill Liner Installation Manual - Policorp PDF - Scribd

Ball Mill Liner Installation Manual_Policorp - Free download as PDF File (.pdf) or read online for free.

More

Cement ball mill process calculation pdf PPT - SlideShare

2024年1月5日 Cement ball mill process calculation pdf - Download as a PDF or view online for free. ... Lifetime of wear resistant products of ball mills (12 % Cr) • Mill inlet (liner plates): 12,000 – 17,000 h • Lifter plates: 35,000 h • Intermediate wall: slot plates: ...

More

Semiautogenous mill liners: Designs, alloys, and maintenance procedures ...

Large-diameter autogenous and semi-autogenous grinding mills represent the primary thrust of the expanding grinding technology. In spite of initial difficulties, large autogenous and semiautogenous mills have reached an acceptable level of technology that provides the mineral engineer with a reliable, low cost means of ore comminution.A successful milling installation

More

Ball mill liner Wear Parts For Industry Qiming Casting

Qiming Casting manufactures manganese, Cr-Mo alloy, chrome, and Ni-hard steel ball mill liners for popular brands ball mills. Skip to content +86 15251744209.: Wear Parts For Industry Qiming Casting.

More

Predicting liner wear of ball mills using discrete element method

2022年6月1日 There are many experimental studies on liner wear, and various approaches have been proposed and implemented to increase the liner life (Banisi and Hadizadeh, 2007, Yahyaei et al., 2009).In particular, based on an experimental study, a liner wear apparatus was developed to monitor the liner wear effect on the grinding performance of ball mills (Powell, 1991).

More- 28hp diesel broyage prix d usine en afrique du sud

- mineral broyage du ciment moulin

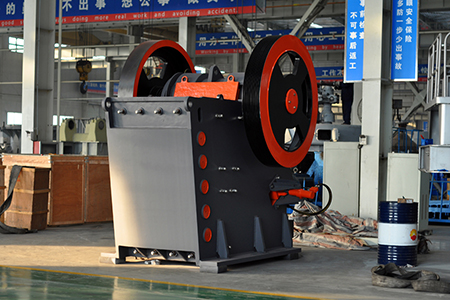

- concasseur finlay jaw

- minerai de Cuivre concasseur prix de la France en Cameroun

- meuler de la matière la machine fungsi cylindrique

- denver flotation cell tech

- Utilisation de la poudre de dolomite

- Fournisseur de broyeur de mâchoires de minerai de fer en indonessie

- trémie de broyeur à boulets avec canvyer sacrw

- usine de concassage de pierre soudanaise

- concasseur à mâchoire principl

- broyeur à barres broyeur à barres

- inconvénients du concasseur à mâchoires denver

- materiau de construction concasseur usine

- forage dynamitage blast