coal wash in spirals

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

KREBS® Coal Spirals for fine coal cleaning - FLSmidth

Spiral coal concentrators use the specific gravity of materials with different densities to separate coal, and produce a low-ash coal product at high efficiency. Our high-performance Coal Spirals deliver a feed capacity of 2 STPH to 3

More

Conventional and recent advances in gravity separation

2023年2月1日 Spirals, also known as spiral concentrators (Fig. 7 b), are flowing film-type separation tools that stratifies particles by gravity. Humphrey's coal spirals are commonly used

More

Mathematical modeling of separation characteristics of a coal

2007年10月19日 An improved mathematical model to simulate the particle and flow behavior in a coal-washing spiral has been developed. The modeling framework addresses three main

More

Spiral (Concentrators) - an overview ScienceDirect Topics

They have been widely utilized in coal washing plants worldwide to treat material in the particle size range 1 mm–150 μm (other reports show that spirals are capable of treating material

More

Conventional and recent advances in gravity separation

2023年1月21日 Humphrey's coal spirals are commonly used to process coal in the size range of approximately 0.15–1.0 mm. It consists of a corkscrew-shaped device that selectively

More

A Study of Coal Washing Spirals - ResearchGate

2007年2月27日 The MODSIM mineral processing plant simulator is used to find optimal combinations of target separation specific gravities for the separation units in a typical coal

More

Development of a high capacity, low cut spiral for the coal

Intermediate discard removal results in the ideal percent solids for a low cut at the final stage. A cut point of 1.53 was achieved with good yields at a high capacity. This spiral configuration,

More

Fine Anthracite Coal Washing Using Spirals Request PDF

2001年5月31日 A new flow sheet of the circuit of the Alborz-Sharghi coal washing plant, which involves two spiral separators is presented.

More

A Study of Coal Washing Spirals - Semantic Scholar

Coal washery rejected coals and coal slurries have better options in froth flotation as a separation process. In this study, coal slurry received from Sudamdih coal washery, Jharkhand, India,

More

A Study of Coal Washing Spirals - Taylor Francis Online

2007年2月27日 A study of coal washing spiral operation and performance is under way at the JKMRC. The program has two components—a pilot plant study, and sampling programs

More

Spiral conditions for the recovery of ultra-fine particles

spirals are treating material too coarse for flotation and too fine for dense-media separation. Powder Technology V 102, pp 244 – 252, 1999 stated that there exists a genuine need for extending the performance envelope of spirals – whether to treat finer or coarser material than the traditional size ranges.

More

Conventional and recent advances in gravity separation

2023年2月1日 The ratio between combustible organic matter and inorganic impurities of coal is also one of the variables in coal classification. Coal gangue is a significant residue of coal mining and cleaning, which accounts for approximately 10–15% of raw coal [3].The first group of impurities in coal, which are also the most commonly encountered, are quartz (SiO 2) and clay

More

MD Spirals - Mineral Technologies

WW Series - utilises wash water addition for enhanced grade control in specific applications (e.g. iron ore) HC Series - super-high capacity spirals specifically designed for more economical and compact plants. The facility to add wash-water is available on some models MD Spirals Designed and manufactured by Mineral Technologies, MD

More

Getting the Most from Spiral Separators - Coal Age

2023年8月25日 Recovering Fine Coal With Spirals. Prep plant operators use spirals in heavy media circuits to treat the size fraction finer than 1 mm, but they can also be used to supplement coal washing jigs treating the fraction finer than 2 mm. They can be used to replace coarse flotation treating the fraction coarser than 0.1 mm.

More

(PDF) Size recovery curves of minerals in industrial spirals for ...

2014年10月1日 Spirals are gravity concentrators used for the concentration of coal, iron oxide ore and heavy minerals. As in any gravity concentrators the separation of minerals in a spiral is based on particle ...

More

Process design of the Phola coal J preparation plant o - SAIMM

DMS equipment used to date in South African coal preparation plants, i.e. 1 150 mm large diameter pump fed DM cyclones and 4.2 m width banana screens. The fine coal is conventionally processed by spirals, whereas the raw coal slimes are filtered using automated plate and frame filter presses and added to either the

More

New Developments in Spirals and Spiral Plant Operations - AusIMM

New Developments in Spirals and Spiral Plant Operations Records indicate that spiral separators have been utilised in mineral separation for over 100 years. The Spiral's predecessor, the sluice, has been in use for centuries in different forms and a spiral can be thought of as a sluice wound around a column. The spiral separator is distinguished from the straight sluice, and other

More

SX7 and MX7 Coal Spiral Concentrators - Multotec

Multotec has designed and optimised the double stage MX7 coal spiral concentrators to process feed with a size range of 2.0 mm to 0.1 mm for difficult-to-wash coal. The 2-stage spirals, the SX7 and MX7, incorporate two stages of spiralling into a single spiral assembly, reducing plant height and floor space requirements – ultimately reducing ...

More

Spiral Concentrators - IMSC Group

Wash water spirals require the addition of water at various points down the spiral and therefore provide a “washing” of the concentrate, i.e., transporting away light gangue from the concentrate band. ... Coal/Mica Spiral Spiral Concentrators. Larger

More

"coal wash plant" in Home Garden Supplies in South Africa

Mining equipment ,Wash plants DMS amp; Jig plants from 50tph-1000tph. For Coal , Gold amp; Diamonds , Chrome. Crushers , Conveyers . New or refurbished Spirals for wash plants , Water pumps ,Slurry pumps , All size Motors for pumps . New or used. Excavators, Trucks ,Side lift Trucks , Diggers , Fork lifts . Earth moving equipment.

More

Spiral Concentrator - Metso

5. Wash water rate. Feed distribution. In a plant operation, it is important to maintain a consistent feed rate to the spiral concentrator banks. The variations in feed tonnages to the spirals should not exceed 10%. It is also important to

More

ICG’s New Beckley Prep Plant Incorporates the Latest ... - Coal Age

2010年5月4日 The Coal Wash Cycle Raw coal travels out of Beckley’s 2,600-ft mine slope on a 3,000 tph 60-inch belt and can either be sent up to a 7,800-ton raw coal silo or bypassed ... The 1 mm x 100 mesh fines are processed in two banks of 10-SX 7 triple start Multotec spirals. The spirals separate coal from the waste using gravity and ...

More

Effect of Wash Water on the Mineral Size Recovery Curves in a

2014年6月1日 Effect of wash water on the recovery of coarse hematite in the concentrate of a test spiral [6]. in Chemical Engineering and Science decrease in the wash water addition will reduce the iron ...

More

Mineral Beneficiation and Processing of Coal SpringerLink

2021年5月11日 The various equipment used to wash coal includes drum separators, jigs, dense media cyclone, spiral concentrators, teeter-bed separators, water-only cyclone, shaking table, and flotation cell and columns. ... Spirals can efficiently treat and recover valuable particles in the size range of 3 mm to 75 μm.

More

The Cost of Saving Money in Coal Preparation

2014年6月19日 Dense-media Vessel and Spirals In the early 1990s, Pittston Coal inherited a simple two-circuit plant that was built to wash surface-mined thermal coal with a dense-media vessel (DMV) circuit and spiral circuit.

More

Leeuwpan fine coal dense medium plant J r n a - CSIR

coal mines in the Exxaro Resources group. The dense media separation (DMS) plant at Leeuwpan was commissioned in 1997. The plant originally treated three Witbank coal seams, namely seams no. 2, 4 and 5. A coal jig plant was built in 2005 to treat the top layer of coal—Seams 4 and 5—to supply a 30% ash coal to power stations. When the jig ...

More

Mathematical modeling of separation characteristics of a coal

2007年10月1日 Spirals are gravity concentrators used for the valorization of ... Results showed that the air-dense medium fluidized bed system is an efficient dry separation method for difficult-to-wash coal.

More

Coal tailings reprocessing and fines recovery

Spirals are very popular amongst the fine coal-cleaning technologies due to low capital cost, ease of operation, and other advantages. Compound rougher – cleaner spirals with middlings recycling give better separation performance (Fig. 4).

More

THE EFFECT OF REPULPING ON THE SX7 SPIRAL - Multotec

available for fine coal are spirals, flotation, dense medium separation (DMS) and water only cyclones. Spirals are primarily used for cleaning coal in the intermediate size range of 100µm to 2000µm. These coal particles are neither large enough for heavy media separation and nor small enough for froth flotation (Kapur Meloy, 1999).

More- carbonate de magnesium poudre mgco3 broyeur

- citations de concasseur dechantillons

- Concasseur D Usine De Concassage De Roche à Vendre

- a coimbatore fabricants

- types pf principe de broyeur charbon

- largeur de la galerie de convoyeur

- Configuration De L usine De Concasseur à Quartz

- Concasseur à cone cador

- Broyeur de minerai de fer en arménie

- minerai de Limonite equipement de traitement usure

- rizeries afrique du sud

- pdf de vibrants calculs de conception decran

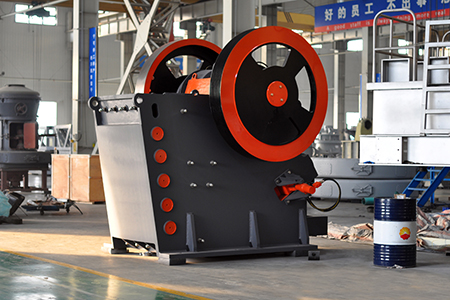

- échantillon concasseur à mâchoires pour le concassage minéral utilisé en laboratoire avec un bon prix

- concasseur à percussion dans suodiarbia ashphalt

- concasseur de pierres à tapak biaya pembangunan