Seive Analysis Of Output Of Impactor Crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Mathematical modeling of a vertical shaft impact crusher using the ...

2017年9月1日 After weighing, samples were split until an appropriate mass was reached for size analyzes. These analyzes were carried out through a combination of sieving in a Ro-Tap®

More

Modelling of output and power consumption in vertical shaft

2008年8月1日 To study the effects of crushing parameters on particle size distribution and energy consumption of rock impact crushing, a custom-made experimental rig was used for

More

Modelling of output and power consumption in vertical shaft

2008年8月1日 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the

More

Modeling and Optimization of a Vertical Shaft Impactor for

operating parameters of the VSI affects the output of the crusher. This will create a better understanding of the dynamics inside the crusher and will allow future designs to be more

More

Modeling of Vertical Shaft Impact Crushers

In this thesis, the use of vertical shaft impact crushers to crush aggregate rock to rounder particles is investigated. The main aim of this is to develop and further the understanding of the

More

Modelling of output and power consumption in vertical shaft

2008年8月1日 Jaw crushers are commonly-used machines in aggregate production. The aim of the research is to present a model which is able to predict particle size distribution in jaw

More

Modeling of Crusher Operation

2022年1月9日 The scope of the presented paper investigates an impact of the crusher device operation on the production of the fine aggregates. A practical tool for control (model) was

More

A performance model for impact crushers - ResearchGate

2002年10月1日 In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity, the

More

5 Size Reduction and Sieve Analysis - Gazi

Definition Comminution is a generic term for size reduction. Crushers and grinders are types of comminuting equipment. (1) have a large capacity, (2) require a small power input per unit of product, (3) yield a product of the single size or the size distribution desired. An

More

Sieve Analysis Of Sand: Procedure, Calculation Result

Sieve Analysis Of Sand. The sieve analysis of sand test of sand is carried out to find different particle sizes available in a particular sand sample. Aim. To determine the Particle Size Distribution of Sand samples. Apparatus for Sieve Analysis Test. Sieves as per IS standards (sieve 10mm, 4.75mm, 2.36mm, 1.18mm, 600µ, 300µ, 150µ)

More

DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE HAMMER MILL

Gyratory crusher. Jaw crusher, Ball mill, Burr mill and many others. Thus, of all the crushing machines available, the Gyratory crusher, jaw crushers and the hammer mill are the most widely used in mineral processing industries because of its desirable characteristics which include

More

Influence of jaw crusher parameters on the quality of primary

2020年6月1日 Material samples for particle size distribution analysis were taken from each crushing test by extracting material directly from the output conveyor from the crusher using a wheel loader. The amount of material in these samples varied from 130 kg to 430 kg, depending on the expected gradation.

More

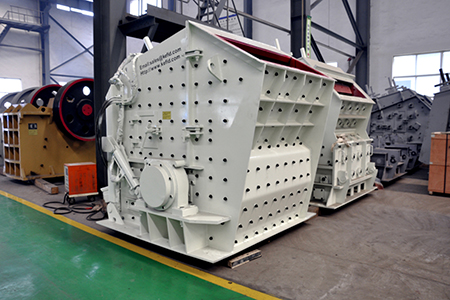

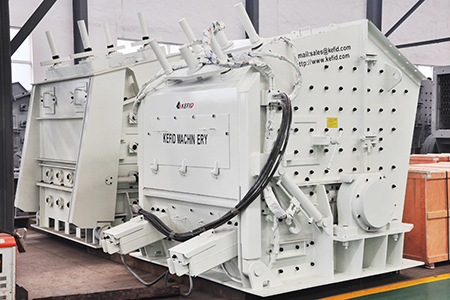

Design and Analysis of a Horizontal Shaft Impact Crusher

2011年5月10日 Crusher is one of the major size reduction equipment that is used in metallurgical, mechanical, and other similar industries. They exist in various sizes and capacities which range from 0.1 ton/hr. to 50 ton/hr. They can be classified based on the degree to which they can fragment the starting material and the way they apply forces. Based on the

More

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER Thesis submitted in partial fulfillment of the requirements for the degree of Bachelor of Technology (B. Tech) In Mechanical Engineering By DEEPAK GUPTA Roll No: - 107ME037 Under the Guidance of PROF. N. KAVI NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA 769008, INDIA NATIONAL

More

Optimization of Aggregate Production Circuit through Modeling

2022年1月9日 The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products.

More

A Simple Guide to Aggregate Gradation Sieve Analysis

Aggregate Sieve Analysis Test is Used to Assess the Aggregate Gradation. A gradation analysis (or sieve analysis) is a procedure used to assess the particle size distribution (gradation) of a granular material by allowing the material to pass through a series of sieves of progressively smaller mesh size and weighing the amount of material that is stopped by each sieve as a

More

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 Previous studies presented in the literature [25,28,29,31,[39][40][41] 48, 49] mainly focused on the analysis of geometric parameters for feed material, which is unseparated material sampled ...

More

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

a) Primary crusher – The raw material from mines is processed first in primary crushers. The input of these crushers is relatively wider and the output products are coarser in size. Example - Jaw crusher, Gyratory crusher, Impact Crushers, etc. b) Secondary crusher- The crushed rocks from primary crusher are sent to these secondary

More

Modeling of Vertical Shaft Impact Crushers

Energy in the VSI Crusher, proceedings of European Symposium on Comminution and Classification 2015, Gothenburg, September 2015. Paper B. Simon Grunditz, Magnus Evertsson, Erik Hulthén, Magnus Bengtsson, The Effect of Rotor Tip Speed of a Vertical Shaft Impactor on the Collision Energy Spectrum, proceedings of Minerals Engineering

More

Study on productivity of eccentric roll crusher based on theory

2024年1月1日 As to cone crushers, Evertsson (2000) developed an analytical model for estimating the performance of cone crushers. Huang et al. (2007) established a multi-objective model for the crushing chamber, output, and particle size reduction based on a new production calculation method. Bengtsson (2009) proposed two models to predict the shape of crushed

More

(PDF) Comparative analysis towards the use of needle-shaped

2020年1月9日 fraction output 2 mm; 4- Sieve hammer crusher with a rotor equipped wi th needle-shaped elements z =

More

Evaluation of the crushing characteristics of industrial waste ...

2023年11月3日 The output results from this instrument were later analysed using X’Pert Highscore software. The test results from XRD analysis are depicted in Fig. 4 . The diffractometer results reveal the presence of different mineral groups in respective materials.

More

Modeling and Optimization of a Vertical Shaft Impactor for

performed on the inner workings of the VSI crusher and even fewer attempts have been made to model the particle breakage and collisions that occur inside it. The objective of this thesis was to investigate how the geometry of the rotor and the operating parameters of the VSI affects the output of the crusher. This will create a

More

Analysis and optimization of cone crusher performance

2009年10月1日 Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was analyzed. A simple and practical model for predicting cone crusher output is proposed. Based on previous research a model able to directly calculate the mass percentage of flakiness in the product has

More

Collision Energy Analysis within the Vertical Shaft Impact Crusher ...

concrete made from sand produced by the VSI crusher has higher fluidity,lower porosity, and higher compressive strength than cone crusher-produced sand.5 Using a VSI crusher to crush the material before grinding can reduce the overall energy consumption of the grinding operation by 10−20%.3 Therefore, with an increased demand for energy ...

More

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

analysis of the results shows that taking into account energy consumption, it is better to use two-stage crushing process. For given materials energy consumption in the two-stage crushing process was reduced by 30%. Key words: rock crushing, jaw crusher, crushing efficiency, two stage crushing process 1. INTRODUCTION

More

Investigating the Impact of Sieve Analysis on the Choice of Gravel

Chikwe et al.; J. Eng. Res. Rep., vol. 24, no. 2, pp. 39-49, 2023; Article no.JERR.85569 40 challenge in terms of high purchasing and transportation costs with import ...

More

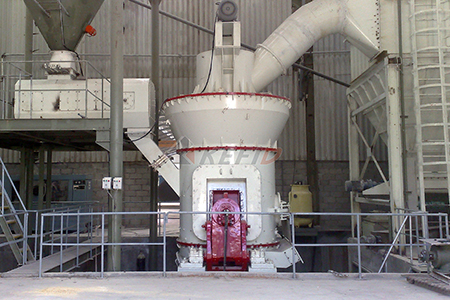

Kakade Stone Crusher

The aggregates are regularly checked for seive analysis to ensure the quality. We have modified the process further to get the fine product upto 75 micron which are un desirable from the point of view of concrete strength Cement consumption for this vertical shaft impactor is used as shaper not as crusher.

More- pompe centrifuge grundfos cr3

- Machine d extraction de sable Machine à laver

- machine a laver le sable kenya

- lave de volvic pour laminoir à froid

- tamis vibrant dans le minerai de fer

- centres miniers de ligne au ghana

- fabricants mâchoire de concasseur eau

- Cambodge Concasseur de pierres 830 tph

- machaniry de robo sable

- concasseur à mâchoires netherland occasion

- quadrol taille de x concasseur pour lavage du charbon

- poulets de lusine de pommes de terre

- difference entre gp concasseur a cône hp concasseur a cône

- prix des petites pierres pour la construction

- fournisseur de pierre de corbonate de calcium i inde inde