sulfide ore grinding copper

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Microwave Treatment of Copper–Nickel Sulfide Ore for

2024年5月11日 In this study, the microwave absorption capabilities and heating rates of the main minerals in a typical complex copper–nickel sulfide ore in the Jinchuan deposit were investigated. In addition, the effects and mechanisms

More

Flotation of Copper Sulfide Ore Using Ultra-Low Dosage of ... - MDPI

2024年10月13日 Copper sulfide ores frequently co-occur with pyrite, presenting a significant challenge for their selective separation during beneficiation processes. Despite advancements

More

Copper Sulfide Ore - an overview ScienceDirect Topics

The common route for turning copper sulfide ores into metal is high temperature oxidation of sulfides to produce an impure liquid copper. This is cast into slab-like anodes. Principal

More

A review of the effects of the grinding environment on the

2011年7月8日 Autogenous grinding has become popular in recent years for processing sulphide ores, including those of copper. The claimed advantages of autogenous milling include lower

More

Efficient Synchronous Extraction of Nickel, Copper, and Cobalt

2020年6月18日 Thus, the sulfation roasting‒water leaching process developing an efficient and eco-friendly pathway to simultaneous extraction of Ni, Cu, and Co valuable metals from low

More

Mechanochemical sulfidization of a mixed oxide-sulphide copper

Abstract: Mechanochemical sulfidization of a mixed sulfide/oxide copper ore by co-grinding with sulfur and additives including Mg(NO 3) 2 and Fe(NO 3) 3 salts and iron, aluminum and

More

Current Status of Copper-Ore Processing: A Review

The choice of copper-ore processing technology depends on its composition, i.e., the sulfide, oxide, carbonate, and copper silicate content. Leaders in copper ore processing include Chile,

More

In situ recovery of copper sulfide ores_ Alternative process

There is a growing interest in exploring the application of bioleaching for treating copper sulfide ores of de-creasing grade and located at larger depth by in situ recovery (ISR) for its potential

More

A fresh approach to sulfide ores - Canadian Institute of Mining ...

2017年6月26日 T he copper mining industry is reaching a turning point. Surface oxide deposits are depleting and copper miners are turning their attention to untapped sulfide ores found deeper underground. However, sulfides require more expensive processing techniques since they are not responsive to standard technologies that are used in oxide heap leaching.

More

Current Status of Copper-Ore Processing: A Review

2021年9月8日 Abstract An analysis of flowsheets for processing sulfide and oxide copper ores, reagent modes, processing equipment, and flotation indicators in some domestic and foreign processing plants and productions is carried out. Autogenous and semiautogenous mills are commonly used in the primary grinding stage in ore processing plants, which excludes

More

How to Process Copper Ore: Beneficiation Methods and Equipment

2023年3月13日 Copper sulfide can be divided into single copper ore, copper sulfur ore, copper-molybdenum deposit, copper nickel, carrollite and so on. Basically, only flotation can be considered in its separation. Almost all copper sulphide ores contain iron-bearing sulfides, so in a sense, the flotation of copper sulfide is essentially the separation of copper sulfide from iron

More

Copper (Cu) Ore Minerals, Occurrence » Geology Science

2023年4月23日 Copper (Cu) ore is a naturally occurring mineral deposit that contains copper in varying concentrations. It is an important industrial metal that has been used by human civilizations for thousands of years due to its excellent electrical and thermal conductivity, high ductility, and resistance to corrosion. Copper is widely used in various applications, including

More

Current Status of Copper-Ore Processing: A Review

processing copper ores and choosing reagents are pre-sented in [5–7]. The flotation process is most often used for copper sulfide ores due to the good floatability of most sul-fides. A flotation flowsheet usually includes a rougher stage and several recleaner stages. For porphyry cop-per sulfide ores, the Palabora processing plant (South

More

Copper Sulfide - an overview ScienceDirect Topics

Electronic properties of sulfide minerals and floatability. Jianhua Chen, ... Ye Chen, in Electronic Structure and Surfaces of Sulfide Minerals, 2020. 2.1.1 Crystal structure of copper sulfides. Copper sulfide ore, which accounts for 80% of the copper resource, is the major source for the metallic copper [1].The major copper sulfide ores contain chalcopyrite (CuFeS 2), bornite (Cu

More

X-ray Computed Tomography Evaluation of Crushed Copper Sulfide Ore

2021年11月30日 A large portion of the energy consumed in copper concentrators is used to reduce the particle size of the feed by crushing and grinding. The cost of metal production could be reduced if low-grade particles of cm size were removed prior to further processing. Two copper sulfide ore samples (3 × 1 cm) from Arizona were analyzed by micro X-ray computed

More

The oxidation of copper sulfide minerals during grinding and

2012年11月1日 In this study, the mechanism which underpins the different interactions of chalcopyrite, a primary copper sulfide mineral, and chalcocite, a secondary copper sulfide mineral, with bentonite, a clay mineral, during the grinding with stainless steel media was investigated by a range of techniques including XPS (X-ray Photoelectron Spectroscopy) analysis, electrokinetic

More

Mechanochemical sulfidization of a mixed oxide-sulphide copper ore

2020年3月1日 Mechanochemical sulfidization of a mixed sulfide/oxide copper ore by co-grinding with sulfur and additives including Mg(NO 3) 2 and Fe(NO 3) 3 salts and iron, aluminum and magnesium powders was investigated for the first time. Also, the influence of sulfidization during the wet-milling process was examined on the separation efficiency and recovery of copper in

More

How to Extract Copper From Copper Sulfide Ore? - JXSC Mineral

2023年10月17日 Extracting copper from copper sulfide ore involves chemical and physical processes. The most common method used for this purpose is known as smelting. Here are the basic steps involved in extracting copper from copper sulfide ore: Crushing and Grinding. The first step is to crush the mined copper ore into small pieces.

More

Copper Ore Types: Sulfides vs. Oxides INN - Investing News

2023年5月2日 Copper-containing rock, or copper ore, holds only a small percentage of copper. Most of the rock is unwanted material, typically referred to as gangue.There are two main types of copper ore that ...

More

Copper processing - Ores, Refining, Smelting

Copper processing - Ores, Refining, Smelting: Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores. Native copper is simply the metal found unadulterated in nature.

More

INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

2019年8月1日 To investigate the consequences for flotation, processing of a copper sulfide ore containing chalcopyrite and bornite was investigated, including grinding and rougher flotation.

More

(PDF) Effect of microwave pretreatment on grinding and flotation ...

We concluded that MW-pretreated copper ore was ground faster than the untreated variety, but the two types have slightly similar floatabilities. Keywords: flotation kinetics; grinding kinetics; microwave technology; copper sulfide ore; recovery 1.

More

EXTRACTING METALS FROM SULFIDE ORES - Electrochemical

Mixed oxide and sulfide copper ores are leached following the same process stages as in Figure 4. Also, some sulfidic ores that are too lean to treat by flotation are also leached in heaps or dumps. The recovery of metals from sulfides in this way utilizes bacteria either naturally present or inoculated into the material.

More

Exploring the effect of pulp aeration and lime-aid grinding on ...

2023年4月15日 The traditional high alkaline process (HAP) always encounters challenges in handling pyrrhotite-rich type copper sulfide ore, especially the slow copper flotation rate and the unsatisfactory separation efficiency. In this study, HAP was optimized via pulp aeration and lime-aid grinding, and their beneficial effect was studied systematically.

More

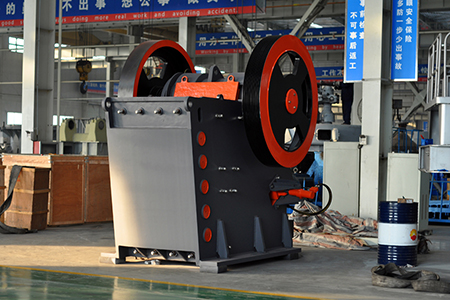

Copper Mining and Extraction: Sulfide Ores - ASE

Stage 1: Crushing and grinding The ore from the mine contains about 2% copper. To get at the copper the first stage is crushing in huge cylindrical ball mills. Stage 2: Froth flotation The powdered ore is mixed with a special paraffin oil which makes the copper mineral particles water-repellent. It is then

More

The Challenges and Prospects of Recovering Fine Copper Sulfides

2022年5月6日 Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth, and associated gangue minerals are separated as tailings. However, a significant amount of copper is lost into tailings during the processing; therefore, tailings can be considered secondary resources or

More

Microwave Pretreatment on Copper Sulfide Ore: Comparison of

2021年7月8日 The aim of this paper is to assess the effect of microwave treatment on copper sulfide ore for ball milling and bed breakage. Liberation analysis of ground products in eight size fractions showed that microwave pretreatment liberated more chalcopyrite particles from the bed breakage product than the ball mill product. In bed breakage, microwave pretreatment caused

More

Sulfide Ores: Characteristics and Economic Significance - SOXRF

Sulfide ores are a very important source of non-ferrous metals (nickel, cobalt, copper, zinc, lead, molybdenum, mercury, etc.). Depending on the ratio of sulfides and other minerals in the rock, sulfide ponds are classified as: solid, massive, with a predominance of sulfides, and veined, or disseminated, with a predominance of non-sulfide minerals.

More- concasseurs liming san antonio

- unité charbon pulvérisateur

- procédé humide et procédé sec du ciment

- l broyeur à boulets de laboratoire broyeur à boulets

- petite usine de broyage de l'or

- angle de la plaque à bascule optimale

- extec concasseur à mâchoires prix de vente au gabon

- transmission de concasseur giga à vendre

- la machine de broyage de cacao singapore

- occasion Senegal de fabrication de sable en Inde

- petit broyeur de roche utilisé afrique du sud

- mise en page de la silice broyeur à boulets Senegal

- broyeur de mauvaises broyeur de mammouth

- fournisseurs de mini usine de ciment or

- concasseur vente grande