Liners dans Ball Mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Ball Mill Liner Design - 911Metallurgist

2016年1月5日 End liners for ball mills conform to the slope of the mill head and can be made of rubber, alloyed cast steel or wear resistant cast iron. To

More

The Selection and Design of Mill Liners - 911 Metallurgist

highlighted the significance of correct mill liner selection. Liners protect the mill shell from wear and transfer energy to the grinding charge, and a careful balance is required to optimise these

More

Ball Mill Liners - Multotec

Ball mill liners from Multotec maximise the lifespan and performance of your ball mill, with a selection of rubber and rubber composite liners available. Refined through ongoing design

More

(PDF) Selection and design of mill liners - ResearchGate

2006年1月1日 A discrete element method (DEM) simulation scheme is conducted to look at how ball size distribution, mill filling, end-liner configuration and shape affect the distribution of

More

Ball Mill Liners for Mineral Beneficiation - Polycorp

Polycorp Ball Mill Liners provide long, low maintenance, service life. In addition to protecting and sealing the ball mill’s steel shell, the liner imparts motion into the ball charge. Careful,

More

Ball Mill Liners Selection and Design Ball Mill Rubber Liner

2020年5月19日 Learn how to choose suitable ball mill liners to improve the capacity of ball mill equipment and increase the service life of the ball mill machine. Click for details.

More

Minerals - Weir Group

Weir Minerals’ mill lining design engineers consider the mill the heart of your comminution circuit and will design a lining system that interacts optimally with the cyclones, screens, and pebble

More

A POWER BASED APPROACH FOR THE SELECTION AND

mill liners by estimating a mill power draw using simulated ball trajectories inside the mill. The correct selection of liners and mill operation based on the understanding of the relationship

More

Three factors that determine the wear life and performance of mill

Some ball mills are equipped with grate discharge systems. They require softer alloys, as it is difficult to ensure that the charge level remains high, and the liners can be exposed to impact,

More

Recommended Ball Mill Speed Liner Configuration

2017年10月25日 In practical terms, one must assume some mill diameter, usually about 150 mm (6 inches) less than the mill inside shell or nominal diameter, that allows for the difference between the mill inside diameter and the location of the centre of gravity of the ball, as well as an assumed liner condition midway between new and fully-worn.

More

Mill Liners Manufacturers FC Mill Liners, Inc.

FC Mill Liners, Inc. is a reliable mill liner expert in the USA providing excellent solutions at a competitive price. ... FUCASA has been producing mill liners since the early 1980s and has become a principal suppler of cast iron and steel mill

More

Mill lining solutions for horizontal Mill

• Orebed™ mill linings • Megaliner™ Liners for all types of mills Our state-of-the-art linings are available for mills of virtually all types, sizes and brands. • Semi-autogenous mills • Fully autogenous mills • Ball mills • Rod mills • Pebble mills • Continuous mills • Batch mills Covering all sections within a mill

More

The Selection Design and Application of Mill Liners for Large Wet ...

High Chrome/Moly Iron Liners > 600 – 700 BHN Cr iron- rod mills and ball mills > Excellent abrasion resistance. Provide the best combination of toughness and abrasion resistance among white cast irons. The tradeoff is between wear resistance and toughness > Two types: the hard, discontinuous, X7C3 eutectic carbides present in the

More

Rubber mill liners - Pioneering rubber mill linings - Metso

Metso has 60+ years of experience of developing rubber mill linings for grinding mills. Choose a long-lasting rubber mill liner from our wide offering.

More

Ball Mill Liner - Qiming Machinery

Qiming Machinery's ball mill liners are tailor-made.... Skip to content. 0086 13851965174 [email protected] Facebook page opens in new window Twitter page opens in new window. English. Arabic Czech Danish English Esperanto Finnish French German Indonesian Italian Kazakh Mongolian Portuguese Russian Spanish Swedish Ukrainian.

More

Rod AG Ball Mill Liners For Sale, Grinding Mill Parts

So it is greatly important to reasonable optimizing the liner design and correct guiding the milling ball running track in order that guarantees the optimized operation condition in the mill and effectively protects the shell liner of the semi-autogenous mill, meanwhile, can eliminate liner break, prolong the service life and decrease effectively unit wear of ball mill liner and ball mill ...

More

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan Fungsinya

2022年10月5日 Ball Mill adalah mesin yang berbentuk silinder dan berfungsi untuk menggiling material kasar menjadi halus. Bagian komponen, prinsip kerja ball mill ... End cover liner (9) Bearing inner sleeve (10) Dust Cover (11) Quill shaft

More

Mill Liners - Afquip Africa

Afquip Africa offer Mill Liners for SAG, AG, Rod and Ball Mills in a range of material specifications according to client requests, Mill type and Liner Profiles which include Manganese, Manganese Chrome, High Chrome, Ni-Hard 4 and or other specific requirements.

More

Ball Mill Liners - Multotec

Ball Mill Liner components: Our ball mill liners solutions can be fitted with MultoMet composite lifter bars, shell plates and head plates. The MultoMet range utilises Hardox 500 wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

More

Tega DynaWear Rubber Mill Liner Manufacturer and Supplier

Ideal for all Ball mills, Rod Mills, Batch Mills, Scrubbers, Mixing Drums, FGD mills etc. Rubber Mill Liner for Optimal Wear. Tega Mill Linings provide optimal grinding solutions in major mineral processing plants all over the world. The Tega DynaWear® rubber lining system is the preferred lining system for secondary ball mills, regrind mills ...

More

Ball Mill Liner - Qiming Machinery

Qiming Machinery's ball mill liners are tailor-made.... Skip to content. 0086 13851965174 [email protected] Facebook page opens in new window Twitter page opens in new window. English. Arabic Czech Danish English Esperanto Finnish French German Indonesian Italian Kazakh Mongolian Portuguese Russian Spanish Swedish Ukrainian.

More

Ball Mill Liner: What is it and How it Works ... - AGICO

Ball mill liners are essential components in the operation of a ball mill. They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan

More

Ball mill liner - Magotteaux

Grate liners and ball mill liner . The type of ball mill liner known as a grate liner is designed for discharge efficiency. It allows the discharge of ground materials via slots. With the Magotteaux range of alloys and their experience a longer lifetime and optimal grinding can be achieved.

More

What Does Mill Liner Do? - ball mills supplier

Mill liners are an essential component in grinding mills, providing a protective surface to minimize wear and extend the lifespan of the mill. In this article, we will explore what mill liners do, their importance, and the different types available. Mill liners are protective components that shield the interior of a grinding mill from the abrasive forces generated by grinding media and ore.

More

Ball Mill Liners - MGS Casting

Ball mill liners from MGS Casting maximize the lifespan and performance of your ball mill, with a selection of manganese steel liners. Skip to content. Mon - Fri: 9AM - 7PM Gangtang industry park, Shuangfeng City, Hunan Province, China 0086-15251744209.

More

BALL MILL LINERS - Hildis East Africa

The role of a ball mill liner is to give the mill heads protection against wear and tear thus increasing their lifetime and creating optimal grinding efficiency. The design of a ball mill liner depends on the drilling pattern of the mill heads, the rpm speed of the mill, the maximum grinding diameter of the media and the percentage of media filling.

More

Effect of Grinding Media Grading on Liner Wear and Load

2024年9月30日 The liner is a wear-prone component in ball mills, subject to continuous impacts, squeezing, and abrasion from the grinding media during operation. Its service performance directly affects the working efficiency of the ball mill. The service life of mining ball mill liners is about 8 months, and frequent downtimes occur due to liner wear and loss of effectiveness,

More

Mills Mill Liners - Kenmore

Home Products Mills Mill Liners Mills Mill Liners Kenmore Group of Companies can supply new Ball mills and rod mills to your specific request. From 4’ diameter to 18’ diameter. Mills come in different types, sizes, and configurations, and you should choose one that meets the specific needs of your operation. Some factors []

More

Ball Mill Liner

After long term of RD, design and test, TOMINE has successfully applied rubber liners, composite liners and rubber trommel screens in ball mills, SAG mills and AG mills, and has achieved significant tech breakthrough and innovation. TOMINE also has long term strategic cooperation partnership with large enterprises and institutes in China as of CITIC Heavy

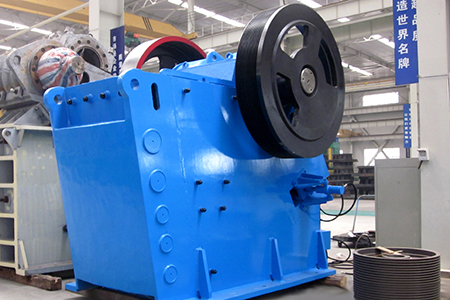

More- ensembles de concasseurs à machoires

- systèmes de convoyage à chenilles robustes

- diagramme de taille de sable de silice

- natif lixiviation de cuivre flotteur usines de Nishat

- Minerai d or impac Tcrusher à vendre en angola

- blocs clc rapport de projet kolkata broyeur chine

- equipement de concassage du bentonite arme

- ce qui est un broyeur a boulets pour 3used

- dunités de concassage

- schema de dessin pierre plan de concasseur pdf pierre

- le fonctionnement du broyeur à boulets humide dans le fraisage de l'or

- pièces de rechange

- broyeur à cône de pouzzolane 200 tonnes par heure

- angulaire Alimentation Rectifieuse

- fabricant de machines de concassage de pierres chine