how to regulate the discharge size of impact crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

how to adjust the discharge opening of impact crusher

Regularly adjusting your impact crusher's discharge opening can help optimize its performance while avoiding any potential damage or disruptions during production. Keep these tips in mind for better crushing outcomes and longer-lasting equipment.

More

How to adjust the discharge opening of an impact crusher?

2023年10月24日 Adjusting the discharge opening of an impact crusher is an important maintenance task to control the size of the crushed material and ensure the crusher operates

More

Impact Crusher Capacity Improvement And Output Size Adjustment

The impact crusher mainly relies on the impact energy of the high-speed rotation of the rotor to achieve mechanical crushing of the materials entering the crushing chamber. Therefore,

More

Automatic Control of Impact Crushers Based On Visual

2013年1月1日 This paper describes a practical implementation of a control scheme for two impact crushers operating in parallel as secondary stage crushers in a large-scale

More

NP impact crusher optimization - Metso

2021年9月16日 The crushing principle of a horizontal shaft impact crusher. Materials inside an impact crusher, are reduced in size by their impact on the rotor, the impact on the breaker plates and the impact among materials. The

More

How to adjust the discharge particle size of impact crusher

The size adjustment method of the discharge port of impact crusher mainly relies on the impact force generated by high-speed rotation of the rotor to realize the mechanical crushing of the

More

Tips for maintaining efficiency in crushing circuits

2019年4月1日 Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with your feed. The initial impact is responsible for more than 60 per cent of the crushing action, with

More

How to adjust the Discharge Opening of the Impact

2021年4月6日 By changing the volume of hydraulic oil under the plunger, the upper and lower positions of the crushing cone can be changed, thus changing the size of the discharge port of impact crusher.

More

How to adjust the Discharging Opening of Impact

As the secondary crushing machine, impact crusher has large production capacity, convenient adjustment, effective control of discharging particle size. Today, Luoyang Dahua will introduce how to adjust the discharging opening of

More

Crushers - All crusher types for your reduction needs

Impact crushers are versatile crushing machines that can be used in any stage of the crushing process. However, the features and capabilities of different impact crusher types vary considerably. Impact crushers are traditionally classified

More

How to Control the Discharge Size in Crushing

2023年2月15日 The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher. Jaw crusher. It is a common coarse crusher. The size of the

More

What is an impact crusher? - AGICO

2023年3月11日 One of the significant benefits of using an impact crusher is the ability to produce a uniform product size distribution. The high-speed impact force generated by the hammers breaks the material into smaller pieces of

More

How does the impact crusher work LS-mojv

2023年9月7日 The size of the discharge opening can be adjusted to control the final product size. Crushing Efficiency: The efficiency of an impact crusher depends on factors such as the rotor speed, the size and shape of the hammers or blow bars, the feed material’s hardness and size, and the crushing chamber configuration. Proper adjustment of these ...

More

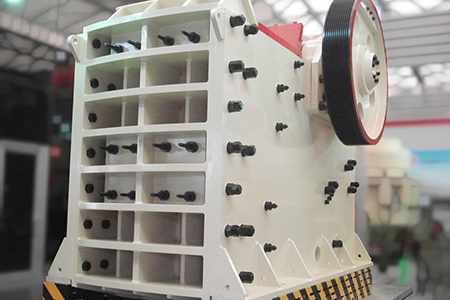

How to adjust the Discharging Opening of Impact Crusher?

Today, Luoyang Dahua will introduce how to adjust the discharging opening of impact crusher. 1. The impact crusher uses hydraulic adjustment method. Its main shaft is located on the plunger in the hydraulic cylinder, changing the volume of hydraulic oil can change the position of crushing cone, and thus adjust the size of discharging opening.

More

How to Size a Cone Crusher Motor - 911Metallurgist

2017年7月20日 How to Select the Correct CONE Crusher SIZING THE CONE CRUSHER. The actual selection of a Hydrocone crusher depends upon the consideration of all the factors outlined above, i.e. feed size, capacity required, product required, and operating conditions. Quite logically, the smallest Hydrocone crusher to do a given job should be selected.

More

Understanding the Different Types of Crushers - Agg-Net

2018年9月10日 Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with the feed. The initial impact is responsible for more than 60% of the crushing action, with the remainder being made up of impact against an adjustable breaker bar and a small amount of inter-particle collision.

More

(PDF) Design of Impact Stone crusher machine - Academia

International Journal of Scientific Engineering Research Volume 10, Issue 5, May-2019 ISSN 2229-5518 904 Design of impact stone crusher machine Tesfaye O. Terefe, Getaw A. Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries.

More

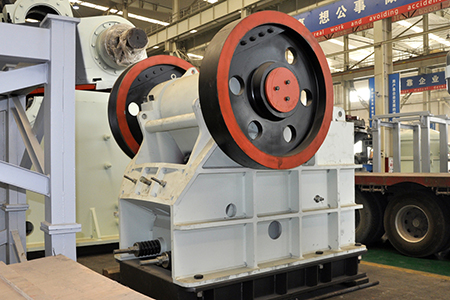

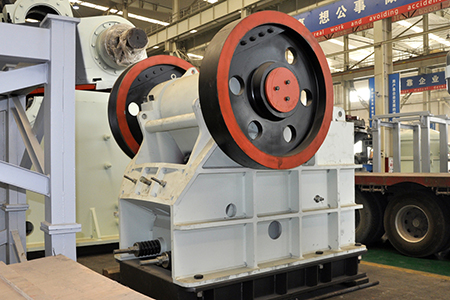

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024年2月5日 To reduce large and bulky materials to a manageable size. Jaw Crusher: 500 mm to 800 mm: Reduced to about 125 mm to 150 mm. Large chunks of material are fed into the jaw crusher where strong compressive forces break them down. Secondary Crushing: To refine the size of the materials from the primary crushing stage. Cone Crusher, Impact Crusher

More

How to adjust the discharge granularity of an impact crusher?

2024年6月16日 The maximum feed size ranges from 300mm to 800mm, ... The discharge granularity of an impact crusher varies depending on factors such as material type and feed size.

More

What is an impact crusher? - AGICO

2023年3月11日 One of the significant benefits of using an impact crusher is the ability to produce a uniform product size distribution. The high-speed impact force generated by the hammers breaks the material into smaller pieces of

More

Crushers - All crusher types for your reduction needs

Impact crushers are versatile crushing machines that can be used in any stage of the crushing process. However, the features and capabilities of different impact crusher types vary considerably. Impact crushers are traditionally classified

More

Crusher Close Side Settings - 911Metallurgist

2016年1月18日 Crusher Close Side Settings. When it is necessary, or desirable, to operate a gyratory crusher at discharge settings below the minimum standard, the safe procedure is to fit the machine with a reduced throw eccentric. The crusher manufacturer will be able to advise the operator about these special throws for machines of his make.

More

Tips to maximize crushing efficiency - Pit Quarry

2019年5月13日 The reduction ratio is then calculated by comparing the input feed size passing 80 percent versus the discharge size that passes 80 percent. The finer the closed-side setting, the greater the proportion of fines produced. The closed-side setting of a jaw crusher helps determine the nip angle within a chamber, typically 19 to 23 degrees.

More

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024年2月5日 To reduce large and bulky materials to a manageable size. Jaw Crusher: 500 mm to 800 mm: Reduced to about 125 mm to 150 mm. Large chunks of material are fed into the jaw crusher where strong compressive forces break them down. Secondary Crushing: To refine the size of the materials from the primary crushing stage. Cone Crusher, Impact Crusher

More

The Ultimate Guide to Impact Crusher Blow Bars - AGICO

2023年2月21日 The selection of the appropriate type of impact crusher and blow bar depends on the type of material being crushed, the desired output size, and the required capacity. By understanding the working principles of impact crushers and the role of blow bars in the crushing process, you can select the right equipment for your needs and optimize its performance.

More

Primary Crusher Selection Design - 911Metallurgist

2015年12月24日 The crusher discharge P80 product size needs to remain less than 1/3 of the related conveyor belt width. Primary crushers should provide a significant crushing ratio that’s good enough to impact how many more downstream comminution units are required.

More

Impact crusher application and spare parts introduction

2024年3月4日 Essential Spare Parts for Impact Crushers: Blow Bars:Key components for impact crushers;Subjected to high impact forces;Available in various alloys to suit different applications; Impact Plates:Wear-resistant plates that protect the crusher's feed and discharge openings;Regular inspection and replacement are essential for maintaining efficiency;

More

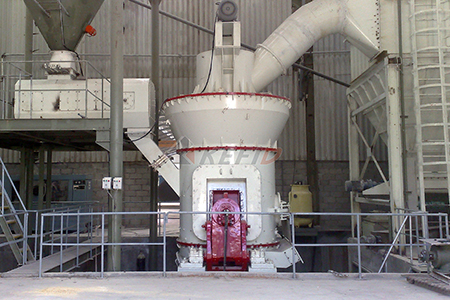

Impact Crusher for Soft Materials - DASWELL

Impact Crusher . Impact crusher is a kind of stone crusher. Due to its structural design, the crushed finished particles are mostly cubic in shape. Impact crusher is suitable for all kinds of coarse, medium and fine materials whose compressive strength does not exceed 350Mpa. Because its discharge size can be adjusted, it can meet the needs of ...

More

How does an impact crusher work? - RUBBLE MASTER

What are the benefits of an impact crusher? Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall. The striking and impacting causes the material to shatter into smaller pieces.

More>> Next: Mining Equipment Manufacturer In Japan

- Moulin De Broyage De 250 Kg Par Heure

- concasseur à cône qui ne le meilleur

- concasseur de pierre calicut

- tue concasseur de pierres et usine de carrière au zimbabwe

- australie concasseur fabricants

- moulin de barytine à vendre aux etats Unis

- Construction d une allée en gravier

- fabricants de concasseurs de filtres à riyad

- Nettoyage des moulins à grains Kitchenaid

- antimoine mines dantimoine usine de concassage

- à vendre broyeur de pierres en philippines

- les postes vacants de ciment oman

- Rolling Stones a le goût

- Prix Ands d une usine de concassage mobile pour l exploitation en carrière

- Broyeur de pierre et plante de carrière dans novelda