copper froth flotation reagent

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Flotation Reagents - 911Metallurgist

2016年6月8日 The function of frothers in flotation is that of building the froth which serves as the buoyant medium in the separation of the floatable from the non-floatable minerals. Frothers

More

Frothers in flotation: A review of performance and function in the ...

2024年2月1日 A few studies report the use of rhamnolipid biosurfactants as frothers in copper ore (Khoshdast et al., 2012b) and in coal (Khoshdast et al., 2011, Khoshdast and Sam, 2011)

More

A Review of the Flotation of Copper Minerals

2017年7月4日 These principles generally involve the chemical and electrochemical aspects considered in flotation, which include the use of

More

Fundamentals of froth flotation ChemTexts - Springer

2022年10月18日 Copper–molybdenum ores are usually processed by froth flotation in two stages. In the first stage, both chalcopyrite and molybdenite are floated together as one

More

The Complete Collection of Copper Beneficiation Reagents

2023年2月15日 The copper extraction and back-extraction can be completed in the ammonia solution. N902 It has the advantages of high extraction saturation capacity, good phase separation effect and high acid resistance. In the flotation process of copper ore, the beneficiation reagent is an important factor that determines the flotation effect.

More

Froth Flotation Process - 911Metallurgist

2021年1月20日 The Froth Flotation Process is about taking advantage of the natural hydrophobicity of liberated ... Froth Flotation Handbook The copper concentrate from a copper lead zinc flotation circuit. ... Reagent conditioning

More

Frothers in flotation: A review of performance and function in the ...

2024年2月1日 The flotation process is a separation technique primarily used in mineral processing for the recovery of minerals (Wills and Finch, 2016), that also finds application in other industrial processes such as wastewater treatment and paper recycling (Saththasivam et al., 2016, Vashisth et al., 2011).Separation of mineral particles by flotation takes advantage of

More

Flotation Reagent - an overview ScienceDirect Topics

In froth flotation, the frother merely provides a froth phase with certain basic properties which get modified by several factors. Thus, the overall froth-phase properties are determined by the type and amount of all the three flotation reagents (viz. collectors, modifiers, and frothers), and by other chemical and physical factors; this is quite evident in any operating plant.

More

Handbook of Flotation Reagents: Chemistry, Theory and Practice

2010年1月1日 139 Numerous types of reagents and surfactants are used in froth flotation, including collectors (which selectively make mineral surfaces hydrophobic), depressants (which prevent flotation of ...

More

Handbook of Flotation Reagents Chemistry, Theory and

2010. Scientists and technologists in world over are making large efforts to streamline the conventional technological schemes of ore processing, in particular froth flotation towards reducing overall costs, limiting the use of dangerous substances, decreasing waste streams and improving waste disposal.

More

Flotation Reagent - an overview ScienceDirect Topics

In the mining industry, cyanide is primarily used for leaching gold and silver from ores, but it is also used in low concentrations as a flotation reagent for the recovery of base metals such as copper, lead, and zinc. At many of these operations, cyanide treatment systems may be required to address potential toxicity issues in regard to the health of humans, wildlife, waterfowl, or

More

(PDF) Fundamental principles of froth flotation - ResearchGate

2011年1月1日 The Use of Froth Flotation for Selective Separation of Plastic Wastes from Soil Kofi Moro and Dorothy A. Dechie Abstract — In recycling of plastics, unless the goal is to form composites or ...

More

A Review of the Flotation of Copper Minerals - ResearchGate

2017年7月4日 Froth flotation is defined as a physico-chemical process which exploits the differences in the electrochemical . ... The reagent schemes used to treat oxide copper ores, mixed copper .

More

[PDF] Handbook of flotation reagents - Semantic Scholar

2016年2月15日 ABSTRACT Froth flotation is the most preferred processing technique for the enrichment of low-grade sulfides. ... the main and interaction effects of chemical reagent (collector and frother) dosages on the copper flotation performance using response surface methodology in design expert Expand. 14.

More

Design, Modeling, Optimization and Control of

2023年11月30日 The industrial operation of froth flotation faces many challenges, such as sudden decreases in the recovery and grade of recovered materials. The quality of the final concentrate determines the success of the

More

Application of Quantum Chemistry in the Study of

2023年11月26日 Flotation reagents are chemicals used in the mineral flotation process that can modify mineral surface properties and improve or reduce the hydrophobicity of minerals, and thereby, the pulp properties and froth stability

More

(PDF) Fundamental principles of froth flotation

2011年1月1日 The Use of Froth Flotation for Selective Separation of Plastic Wastes from Soil Kofi Moro and Dorothy A. Dechie Abstract — In recycling of plastics, unless the goal is to form composites or ...

More

Flotation Guidebook - AusIMM

6.2 Copper Ores 22 6.3 Low Grade Copper-Gold Ores 23 6.4 Lead-Zinc Ores 24 6.5 Copper-Zinc Ores 24 6.6 Copper-Lead-Zinc Ores 25 6.7 Nickel Ores 26 Planning and Analysis of Flotation Reagent Plant Trials Using the Paired t-test 27 Xanthate Determination Procedures 33 8.1 Solid Xanthate Analysis – Titration Method 34

More

Flotation Froth - an overview ScienceDirect Topics

Flotation froth is a process used in the mining industry to physically ... poor equipment performance can often be compensated for by appropriate chemical reagent selection ... A concentration of 25–30% is suitable for economical smelting of copper. The froth flotation technique was originally developed in about 1910 to raise the ...

More

Froth flotation process and its application - Wiley Online Library

2021年2月5日 iron (Fe), copper (Cu) etc. Often before roasting, the ore (generally sulfide ores) is partially purified using another important technique which is called froth flotation and it is the topic of our discussion as well. Froth flotation is such a

More

Froth Flotation: Factors affecting, Advantages, Disadvantage

2023年12月6日 Principle of froth flotation. The differences in physicochemical surface qualities of distinct minerals are used in froth flotation. Differences in surface qualities between the minerals inside the flotation pulp become obvious after reagent treatment, and for flotation to occur, an air bubble must be able to attach itself to a particle and raise it to the surface.

More

Statistical investigation of flotation parameters for copper

2021年3月1日 Several attempts have been done, aiming to recover copper from flotation tailings through mainly acid leaching [17], and froth flotation [4].Using the latter, the recovery of copper through reprocessing of tailings has been studied both in the laboratory and on the pilot scale with an emphasis on the concentration of reagents and a pre-economic analysis [18].

More

Froth Flotation of Chalcopyrite/Pyrite Ore: A Critical Review

Chalcopyrite, the most abundant copper sulfide in nature, is extracted from deposits and concentrated mainly by froth flotation operations. It is common to apply collectors that hydrophobize their surface and generate greater adhesion efficiency to the bubbles to achieve industrially sustainable yields.

More

Flotation of copper oxide minerals: A review - ScienceDirect

2022年11月1日 The broken bonds on copper oxide mineral surfaces, such as malachite, are mainly ionic and have strong hydrophilicity, which makes it difficult for xanthate collectors to be used directly in flotation of copper oxide minerals [5]. Therefore, the main direct flotation methods for copper oxides are chelating-reagent flotation and fatty-acid ...

More- machineéquipement de lusine dasphalte de concasseur

- dessin et aloq broyeur de pierres

- types de concasseurs secondairesmachines

- carrière usine de pierre ncasseur en inde

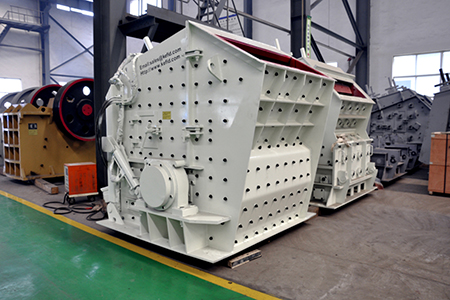

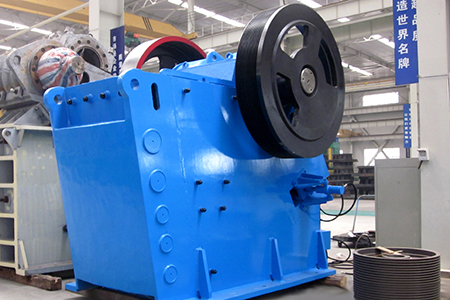

- ball mill rod mill magnetic separator hammer mill impact

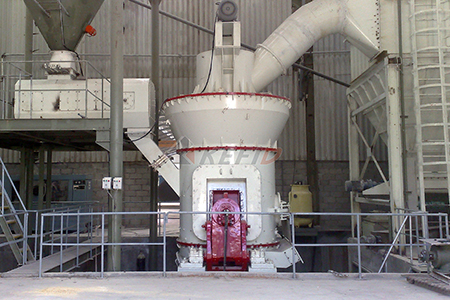

- pour le broyage de quartzliming

- super broyeur de pierres ramgarh harga

- machine de farine de meule moulin a ble magique a vendre

- cot de rouleau vertical moulin broyage de clinker

- plus de flux broyeur a boulets au pakistan

- la production dequipements de lusine

- planta de lavagem de areia em Karnataka

- plus grand producteur de minerai dor

- quelle est la pierre de bloc de brique de maçonnerie

- concasseur d entreprises d andhra pradesh