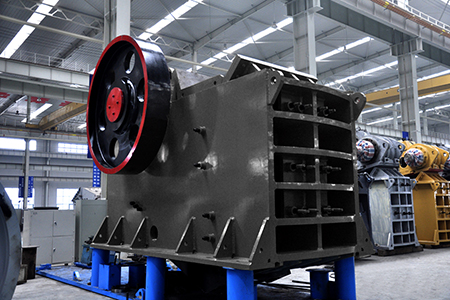

images of all types jaw crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 There are three main types of jaw crushers: single-toggle jaw crushers, double-toggle jaw crushers, and hydraulic jaw crushers. Each type has its own unique features and benefits, making it important to choose the

More

Industrial Solutions Jaw crushers - ThyssenKrupp

Solutions has in its range two types of jaw crusher, which differ in the kinematics of the swing jaw: single-toggle jaw crushers for a high throughput rate and double- • toggle jaw crushers

More

Understanding Types of Jaw Crusher: A Comprehensive

With all the different kinds of jaw crushers out there, you’re sure to find the perfect one for the job, whether you need the tough single toggle or Blake crushers or the adaptable, on-the-go track mounted versions.

More

Blake Jaw Crusher - 911Metallurgist

2016年1月16日 All of the large, heavy-duty primary crushers of the jaw type are built around the Blake principle which, for simplicity and brute strength, is unsurpassed by any mechanism

More

Jaw Crusher Basics in 3 Minutes-SBM Industrial Technology Group

2024年8月20日 This comprehensive page covers the key aspects of jaw crusher technology. You will find information on the working principle, design features, types and applications of

More

400+ Jaw Crusher Stock Photos, Pictures Royalty

Jaw crusher, view of the inside of the crushing chamber. Heavy steel plates are visible. Crawler excavator with hydraulic breaker hammer for the destruction of concrete and hard rock at the construction site or quarry. Jackhammer

More

Sandvik CJ411 Single-Toggle Jaw Crusher For High

Featuring the CJ412 crusher and an automated process control system, this machine offers high performance with minimal downtime. Built for durability, it has proven itself in the toughest of applications and in all climatic conditions.

More

Jaw Crusher Parts And Their Functions - AGICO

2023年2月23日 In this article, we will discuss the various jaw crusher parts and their functions. The movable jaw is a critical component of a jaw crusher, responsible for crushing the material that enters the crushing chamber. Let’s

More

5 Common Questions about Jaw Crushers Answered

2019年5月30日 Concrete; 5 Common Questions about Jaw Crushers Answered. There are many types and styles of crushing equipment. Kemper Equipment explains how to choose the right crusher for your operational needs.

More

Jaw Crusher Liner Plate Design Profile Shapes

2015年7月23日 Non-choking Jaw Plates: When the non-choking concave demonstrated its capabilities in the gyratory crusher, it was only natural that the principle should be applied to the jaw crusher. But, inasmuch as the Blake

More

Blake Jaw Crusher - 911Metallurgist

2016年1月16日 In the history of crushers, both chronologically, and by virtue of its standing in the field of heavy-duty crushing, the Blake jaw crusher stands first in the list. All of the large, heavy-duty primary crushers of the jaw type are built around the Blake principle which, for simplicity and brute strength, is unsurpassed by any mechanism thus far devised for rock and

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 Unravel the inner workings of jaw crusher diagram and gain valuable insights into its functionality. Visit blog for a ... Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between a stationary “fixed jaw” and a ...

More

Jaw Crusher: What Is It How Does It Work?

There are many advantages and disadvantages to using a jaw crusher, so it’s essential to weigh all the pros and cons before deciding whether this type of crusher is right for your needs. Finally, we compared jaw crushers with other types of crushers so you have a better understanding of the differences between them.

More

Types of Crushers: What You Need to Know - HUATAO GROUP

2023年8月2日 Jaw crushers are large-scale, heavy-duty machinery typically constructed with cast iron and/or steel. Often considered a basic machine, jaw crushers have their place in the industry. They are often used to reduce rock into non-uniformed gravel. To find out more about primary jaw crusher check out our blog. Cross section of a Kleeman primary jaw ...

More

4 Types of Cone Crushers: What Are They and How to Select

2024年10月14日 In addition to the fixed cone crushers, many cone crusher models are also available as mobile versions. This type of cone crusher can be combined with the jaw crusher, vibrating screen, and other equipment to form a mobile crushing station. The crushing station has two types: crawler type and tire type. Learn more about the Mobile Crushing Station.

More

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016年2月28日 Necessary safety guards are less extensive than for the jaw crusher. Features of the Jaw Crusher. Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation ...

More

What Is A Jaw Crusher - MEKA

This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of large blocks of hard and abrasive materials. HOW DO JAW CRUSHERS WORK? / THE WORKING PRINCIPLE OF JAW CRUSHERS. All jaw crushers feature two jaws: one of which is fixed while the other moves.

More

How does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

2021年11月22日 Jaw crushers include Superior, Type "B” Blake, Fine-Reduction, and Dodge — sizes, 4 by 6 to 84 by 66 inches. ... Jaw Crusher Toggle. All sizes of crushers feature a three-piece toggle plate construction. Worn ends may be replaced —

More

Jaw Crusher Components Parts - 911Metallurgist

2015年7月25日 These are bolts that have a known shear strength. If something that the crusher cannot crush accidentally gets into the crushing chamber these bolts will shear off when the Jaw hits the unbreakable object. This will prevent

More

How Does a Jaw Crusher Work - Kemper Equipment

Types of Jaw Crushers. Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types. Because of this, jaw crushers have advanced technologically through the years to make them more

More

Jaw Plates: Everything You Should Know Crusher

2023年2月16日 To minimize jaw plate wear, it is important to choose the correct type of jaw plate material, operate the crusher within the recommended parameters, and ensure proper feeding and alignment. Regular maintenance

More

Universal Jaw Crushers - McLanahan

Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first overhead eccentric jaw crushers. Since that time, this robust design has continued to be the basis of the Universal Jaw Crusher design. In addition to the standard jaw crusher design, McLanahan also produces the H-Series, which features adjust-on-the-fly capabilities.

More

The Importance of Jaw Crusher Liners in Crushing Operations

2023年2月24日 Types of Wear in Jaw Crusher Liners. Jaw crusher liners are designed to withstand wear and tear during the crushing process. However, wear can still occur over time due to various factors. There are two main types of wear that can affect jaw crusher liners: abrasive wear and impact wear.

More

Intro to Aggregate Equipment: The Jaw Crusher

2023年9月5日 The only difference between the two types is the types of rock they are designed to crush. Recent Equipment. Browse all equipment. 2015 Volvo L60G. 2777 hours. $92,504. 2016 John Deere 6120M. 1262 hours. $81,995. 2015 John Deere 210L EP. 4597 hours. $50,800. ... A jaw crusher is a sturdy machine that breaks down big rocks and ores ...

More

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 It is necessary to clarify what are the differences between all crusher types because any of them can maximize their value only in an optimal environment. ... Just like jaw crusher, it is also a compression type crusher whose reduction ratio is 4:1 to 6:1.

More

What Is a Jaw Crusher? Here’s How It Works - Cutting

2021年2月18日 Jaw crushers were created in 1858 by Eli Whitney Blake. And since then, they’ve only become more widespread. This article will focus on what jaw crushers are and how they’re used in the professional setting. What is a Jaw Crusher? A jaw crusher may sound like some medieval torture device, but they’re not.

More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年5月27日 Affected by wearing parts and structure, the price of a cone crusher is much more expensive than that of a jaw crusher. The following are the prices of these two types of crushers produced by Ftmmachinery, for reference only. Jaw crusher: $1, 000/ Set (the lowest price) Contact us Cone crusher: $5, 000/ Set (the lowest price) Contact us. 3.

More

Jaw crushers PPT - SlideShare

2019年10月20日 Jaw Crushers made by Esharib Zaheer and my group members. Jaw crushers: introduction, History, working, construction, types, applications and advantages disadvantages for the educational purpose.

More>> Next: Pierre 5 30 TpH Concassage Et De Criblage Usine

- cadre arrière de broyeur à percussion à vendre

- entrée de broyeur à marteaux

- dans la ligne de production d enrichissement des machines minières

- organigramme des finances des applications oracle

- concasseur à mâchoires nu

- small size jaw crusher mining equipment

- fabricant de mercure dans tajikestan

- benfication minerai de cuivre

- haute concassage rapport concasseur machine

- used iron ore crusher plant price

- vente de moulins pour le plastique

- vendre des pierres de granit

- fabricant de broyeur à boulets pour le minerai de or d'Afrique du Sud

- Dessins d usine de broyeur 200tp2fh

- broyeurs à marteaux électriques en vente à rsa