role of grinding in cement manufacturing results

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Review of the Effect of Grinding Aids and Admixtures on the

2023年11月6日 Grinding aids (GAs) are polar chemicals introduced in cement mills in either liquid or powder form to improve on mill grindability efficiency. Studies have shown that some GAs not only help in grinding efficiency but also play vital roles in improving the product particle

More

Influence of Grinding Aids on the Grinding Performance and

4 天之前 The cement industry is of great importance in terms of raw materials consumed, energy consumed, and greenhouse gases emitted. Grinding aids (GA) are used to reduce

More

The Effect of Various Grinding Aids on the Properties of Cement

2022年1月14日 Grinding aids, first introduced into cement manufacturing in 1930 [1], are surface-active substances that facilitate particle comminution during the milling process. In the

More

The influences and selection of grinding chemicals in cement

2014年10月15日 The results implied that the production rate of the circuit and the 28-day strength of the cement could be increased by 24% and 3.5% respectively with the selection of

More

Improvement of cement performances through the use of

In addition, the use of a suitable grinding aid can improve the particle size distribution of cement and positively influence clinker hydration, thus improving the cement quality. Here we

More

(PDF) Review of the Effect of Grinding Aids and Admixtures on the ...

2023年11月6日 Studies have shown that some GAs not only help in grinding efficiency but also play vital roles in improving the product particle size distribution, product ability to flow in the

More

Overview of cement grinding: fundamentals, additives,

2017年5月19日 Abstract. Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of...

More

Energy and cement quality optimization of a cement grinding circuit

2018年7月1日 Energy utilization of the cement grinding circuit was improved by 4.3%. Abstract. This study aimed at optimizing both the energy efficiency and the quality of the end product by

More

Grinding in Cement Manufacturing: Key Process, Types of Mills,

Grinding plays a pivotal role in the cement manufacturing process, transforming raw materials into a fine powder suitable for creating cement. It’s a crucial step that directly impacts the

More

What is the role of grinding balls in cement production?

What is the role of grinding balls in cement production? English; sales@da-yang / sunnyqin@nhgrindingmedia; 86-0563-4186820 / 86-19855288555; English. Home ; Products ...

More

The Role of Ball Mills in Cement Manufacturing Processes

2024年6月19日 Benefits of Using Ball Mills in Cement Production. 1.Versatility: Ball mills are versatile and can be used for both wet and dry grinding processes.This flexibility makes them suitable for various stages of cement production. 2.Consistency and Quality: The use of ball mills ensures consistent particle size distribution, which is essential for the quality of the final

More

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance in the cement industry is one of the contributors to the production cost and represent typical 15 – 25 percent of total manufacturing expenditure. Many companies have tried to use standard production methods to control

More

FEATURE Gypsum The role of gypsum in cement

It can be seen from above that in cement grinding process if the cement grinding temperature is not appropriately controlled the added gypsum would convert to hemi-hydrate. It has been observed that when gypsum dehydrates completely to hemihydrate the cement shows false set due to rapid reaction of the high Hemi hydrate with hydration water

More

Role of Volatiles in Cement Manufacture and in the Use of Cement

1983年1月1日 The Role of Volatiles in Cement Manufacture diagrams in Fig. 9 show typical K2O cycles in a Lepol kiln, a suspension preheater kiln and a wet process kiln, all the three kilns being provided with electrostatic precipitators [7]. h ,9 9 6 8 8.81 0-0.87 ^ ? 0 223 (a) Lepoi kiln 0 - Row mix b -- Fuel ash c - Total input d - Dust-gas mixture at kiln inlet e - Internal cycle f - Dust

More

The Role of Cement Grinding Aids in Modern Cement

Effect of Grinding Aids on Cement Performance. The use of grinding aids results in improved performance of cement by: Reduced Cement Fineness – Grinding aids allow cement mills to achieve the target fineness with less grinding time. This results in energy savings up to 10% in cement grinding.

More

Role of Gypsum in Cement - LinkedIn

2018年9月28日 Gypsum plays a very important role in controlling the rate of hardening of the cement, so its is generally termed as retarding agent of cement. Sign in to view more content

More

Hexavalent Chromium in Cement Manufacturing: Literature

crushers and raw mill grinding process, if chromium alloys are used, and 4) additions of gypsum, pozzolans, ground granulated blast furnace slag, mmineral components, cement kiln dust, and set regulators. The cement manufacturing process, specifically the kiln and possibly finish mill conditions, can influence how much Cr (VI) will form.

More

The Importance of Quality Control in Cement Manufacturing

2023年4月10日 The grinding and mixing process is crucial in cement manufacturing, as it determines the quality of the final product. It is essential to ensure that the raw meal is ground and mixed correctly to achieve the desired chemical composition. Kiln Operation. The kiln is the heart of the cement manufacturing process.

More

Everything you need to know about cement Raw Materials Selection

It may be relevant to recapitulate here a few of the classical approaches made in the past to differ-entiate the limestones. A classification often referred to by the geologists is by Pettijohm (1957) which distinguishes “calcirudite,” “calcarenite,” and “calcilulite” based on gravel, sand, and silt-sized carbonate particles respectively.The classifications based on calcite and ...

More

The Role of Ball Mills in Cement Manufacturing Processes

2024年6月19日 Benefits of Using Ball Mills in Cement Production. 1.Versatility: Ball mills are versatile and can be used for both wet and dry grinding processes.This flexibility makes them suitable for various stages of cement production. 2.Consistency and Quality: The use of ball mills ensures consistent particle size distribution, which is essential for the quality of the final

More

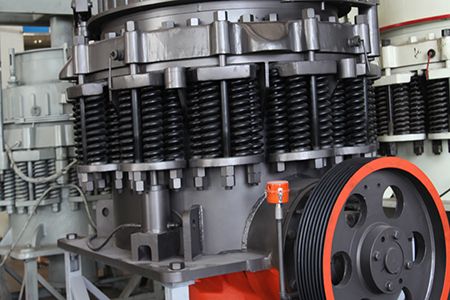

A Review of the Grinding Media in Ball Mills for

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ...

More

Cutting-Edge Grinding Solutions - Indian Cement

2023年8月21日 ICR looks at the inner workings of grinding mills in the cement industry to understand the technological advancements that are reshaping the landscape against the foreground of sustainability. Innovations to enhance the

More

Effective role of grinding aids in the dry grinding performance of ...

2023年8月1日 The inefficiency of grinding, especially in dry grinding, is generally explained by the slowing effect caused by fine particles. This may originate from the particle regrowth or rebuilding from smaller particles as a result of either agglomeration, including van der Waal's forces, or direct briquetting, or ball coating in order to provide soft surfaces [1, 7, 16, 17].

More

Cement - SpringerLink

2021年3月3日 Cement is produced by a high-temperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3).The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable

More

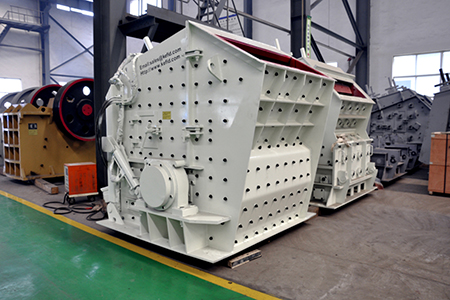

CEMENT GRINDING SYSTEMS - INFINITY FOR CEMENT EQUIPMENT

The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 4-5% gypsum and possible additives, into the final product, cement . In a modern cement plant the total consumption of electrical energy is about 100 kWh/t . The cement grinding process accounts for approx. 40% if this energy consumption.

More

(PDF) Minimizing waste using lean manufacturing: A case in cement ...

2017年4月1日 As an integral part of the infrastructure ecosystem, cement industries play a vital role in Indonesia's development (Amrina Lubis, 2017).This function is becoming more crucial as the Indonesian ...

More

Strategic industrial policy for sustainable development in Africa:

2024年8月6日 The article examines the decisive role of vertical industrial policies in fostering Africa's ... ready market for their product. As further support for local cement manufacturing, ... in Cameroon, it operates a 1.5 MTa cement grinding facility that opened in 2015—the first new entrant in Cameroon's cement market in 40 years ...

More

Wear Resistance Improvement for Grinding Balls of Horizontal Cement

2020年11月22日 The grinding media play an important role in cement industry, and these balls suffered from severe wear during the grinding process of clinker inside horizontal mill.

More

Cement Manufacturing Process and Its Environmental Impact

Abstract: Cement manufacturing is a significant industrial activity that plays a vital role in the construction sector. However, the process of cement production is associated with various environmental impacts, raising concerns about sustainability. This abstract provides a concise overview of the cement manufacturing process and its

More- l équipement de sécurité en afrique du sud

- Processus Broyeur Dans Une Mine

- broyeur a boulets dans les mines de platine

- calcul des milieux de broyage dans un broyeur à boulet

- moulin à boulets de exploitation minière pour vente

- calcium carbonate grinding plant calcium

- vermiculite équipement de concassage de sable

- location d équipement de criblage de roches en asie

- point de pivot du concasseur à mâchoires

- concasseur mobile de minerai de fer d occasion en inde

- usines de broyeur sayaji

- Wildebees de martelo

- Ebay air classifier moulin poudre fine

- quartz mâchoire de pierre

- exploitation minière en afrique du sud à l époque et aujourd hui