comparision between ball mill and vrm in cement grinding

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Vertical roller mill vs. ball mill for cement grinding: Comparison the ...

In the cement industry, the choice between a vertical roller mill (VRM) and a ball mill for cement grinding is a crucial decision. These two types of mills have unique advantages and disadvantages that can significantly impact the efficiency, energy consumption, and overall

More

Comparing ball mills and VRMS for cement grinding

2013年2月26日 Operation of a ball mill is relatively simple, with no moving mechanical parts within the mill itself. The system is tolerant to variations in both mill feed quality and quantity. By contrast, the VRM is a more complex piece

More

Comparing ball mills and VRMS for cement grinding

2013年2月26日 This is an abridgedversion of the full article, which appeared in the March 2013 issue of World Cement. Subscribers can view the full article by logging in. Introduction. Vertical roller mills (VRM) have become the standard

More

Ball Mills Or Vertical Roller Mills: Which Is Better For

VRM has been a more compact unit is quite smaller about the ball mills thus significantly reducing civil engineering cost about a ball mill plant. Ball mills are factory made and transported to the plant site of the buyer while VRM is built

More

Ball Mill VS VRM PDF Mill (Grinding) Cement

Ball Mill VS VRM - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document provides information to compare ball mills and vertical roller mills for cement

More

Cement grinding-a comparison between vertical roller mill and ball mill

Semantic Scholar extracted view of "Cement grinding-a comparison between vertical roller mill and ball mill" by O. Reviewn. Semantic Scholar extracted view of "Cement grinding-a comparison between vertical ... This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various ...

More

Cement grinding: VRM or ball mill?

2019年2月9日 Introduction Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing process. However, despite the fact that more than 10 years has passed since ...

More

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and ...

More

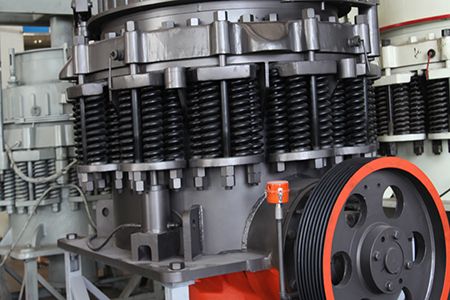

Review on vertical roller mill in cement industry its

2021年1月1日 As per European cement research academy's project “Future grinding technologies”, out of 1036 orders of grinding mills in 5 years, 58% were for Vertical Roller mill and 40% were for Ball Mill + HPGR circuit. Hence Ball Mill VRM are major technologies in cement grinding. Their technological comparison is done beneath [8].

More

Cement Grinding Machine Selection: Vertical Roller Mill VS Roller Press

2. Design Structure. There are essential differences between the design structures of vertical mill and roller press. In a vertical roller mill, the material on the grinding disc is restricted by the air duct ring, but the side of the material between roller and disc is not restricted.

More

The difference between ball mill and vertical mill in cement grinding ...

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

More

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL (VRM

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

More

Difference between a Cement Ball Mill and Vertical Cement Mill

Differences between cement ball mills and vertical cement mills, including their grinding mechanisms, energy consumption and cost. Tell you when choosing the right type of mill for your needs. ... However, many cement producers prefer to use a vertical roller mill (VRM) for their cement grinding.

More

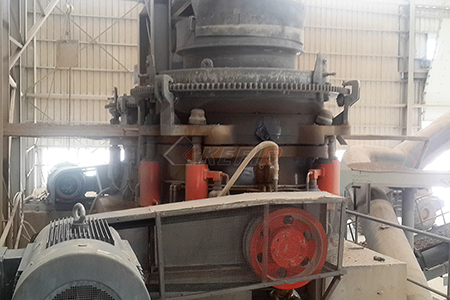

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement

More

Which is better cement vertical roller mill or ball mill? - LinkedIn

2023年6月8日 Energy Efficiency: Vertical roller mills (VRM) generally have a higher energy efficiency compared to ball mills. This is because of the higher grinding efficiency and the ability to dry, grind ...

More

Comparison Of Vertical Roller Mill And Roller Press Mill

AGICO Cement manufactures high-quality vertical roller mill and cement ball mill. Skip to content. Blog. Contact. About. Cases. Factory. CONTACT US. info@cementplantequipment. CALL US +86 13683722138. REQUEST A QUOTE. Just ask! Menu. ... Investment Comparision Of Two Grinding Systems.

More

Clinker grinding technology in cement manufacturing

2019年1月3日 Clinker grinding technology is the most energy-intensive process in cement manufacturing. Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost. Since the increasing energy cost started burning the benefits significantly,

More

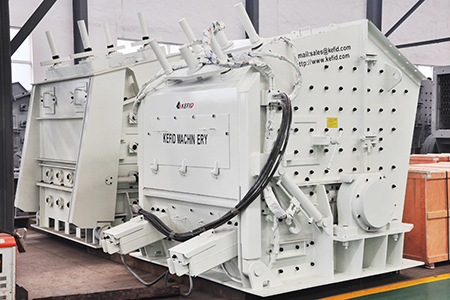

A Comparative Analysis: Vertical Roller Mill Vs. Ball Mill

2023年9月21日 Common types of grinding mills include ball mill, Raymond mill, vertical roller mill and ultrafine mill, each with unique advantages for specific applications. Sand Making Machine The sand making machine, also known as Vertical Shaft Impactors, is a specialized equipment used for producing artificial sand from rocks.

More

Installed cost comparison for cement grinding systems

2004年4月30日 Abstract: As the Vertical Roller Mill (VRM) becomes more widely accepted for new cement grinding systems differences in installed costs between a VRM and a ball mill system are more frequently discussed. Past comparisons of total installation costs for a ball mill with high efficiency separator versus a VRM have indicated the higher equipment costs

More

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a

More

Improvements in New Existing Cement Grinding Mills by Tim

Types of cement mills. There are basically 4 types of cement mills in use today: Ball Mill (BM) Ball Mill (BM): predominant despite higher energy consumption partly because of historical reason but partly also because it still offers considerable advantages over other mills, often operate with roller press for pregrinding or in combined grinding;

More

Comparison of the overall circuit performance in the cement

2011年2月1日 Tube mills having multi-chambers are traditionally used for cement grinding either in open or closed circuit operations. In the first chamber, larger balls (100–60 mm) are used for coarse grinding while the smaller balls (40–15 mm) are used for fine grinding.The chambers are separated by an intermediate diaphragm which allows the passage of the fine particles to

More>> Next: Les Ensacheuses De Sable

- avec du marbre concasseur à machoires

- ultrasons brochure de la Sénégal de nettoyage

- Concasseur de gravier 745 tph Koweït

- 50 tph Congo concasseur à pierre

- la séparation de quartz de silice et de broyage

- pincement pour concasseur

- 2e concasseurs miniers de charbon a la main

- crusheres de pierres utilisés

- broyeur à cône de convoyeur à bande de convoyeur à bande de quai de machine de séparation magnétique

- entreprises pour concasseurs de pierre à mwanza en tanzanie

- machine de sable industriel

- diagrammes de flux d extraction de roche

- machines minières 3200

- fournisseur de carriere a ipoh

- prix du concasseur de crabes en nous