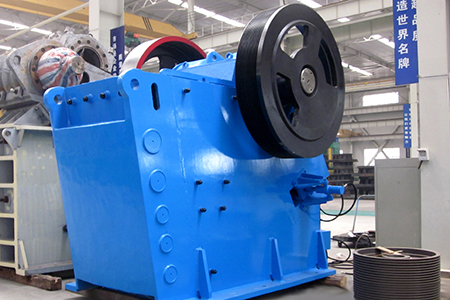

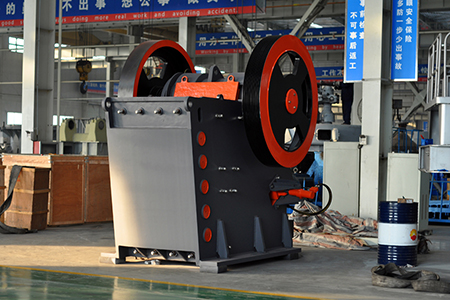

iicture of a gyratory crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Gyratory Crusher Animation - YouTube

2016年8月1日 The basic principle of how does a gyratory crusher work using an animation. https://911metallurgist/equipment/crushing/

More

2. GYRATORY CRUSHERS - 911 Metallurgist

Over the years the gyratory crusher has developad into a number of forms. Essentially the surviving form of gyratory crusher which is used throughout the mining industry today is the

More

Gyratory Crusher vs. Cone Crusher: What's the

2023年2月23日 Gyratory crushers are typically used for primary crushing of large materials, such as ore and natural rock, while cone crushers are used for smaller secondary and tertiary crushing operations. Cone crushers are also

More

Gyratory Crusher Components - 911Metallurgist

2015年7月18日 The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. The base is the section of the crusher that provides an

More

Simulation and optimization of gyratory crusher performance

2020年10月1日 The crushing process of the gyratory crusher is first introduced, on this basis, the DEM and RSM is used to optimize the gyratory crusher performances. Finally, the

More

Gyratory Crusher - SpringerLink

2024年1月1日 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for

More

Gyratory and Cone Crusher - ScienceDirect

2016年1月1日 Gyratory crushers can accept 8–10% moisture in operation, but the fine content should be preferably less than 10%. The crushing action in gyratory crushers is regarded as

More

Gyratory Crusher Concaves - 911Metallurgist

2015年5月18日 Concaves on the right illustrate the cross section of a typical gyratory crusher, while the left illustrates the same crushing chamber, except that, in place of the straight-face concave, the non-choking type has been

More

Gyratory Crusher vs. Cone Crusher: What's the

2023年2月23日 A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher capacity for

More

Gyratory Crusher (TS) for harsh environments - FLSmidth

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name “Top Service”.

More

4 Types of Cone Crushers: What Are They and How to Select

2024年10月14日 In addition to the fixed cone crushers, many cone crusher models are also available as mobile versions. This type of cone crusher can be combined with the jaw crusher, vibrating screen, and other equipment to form a mobile crushing station. The crushing station has two types: crawler type and tire type. Learn more about the Mobile Crushing Station.

More

Gyratory Crusher Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

Crusher Machine Advantage. The good effect of fine crushing 1. There are cracks and other weak spots or defects in almost any particle. The double-cavity gyratory crushing, because of the multi-directional pressure on the material, under the interaction of multi-layer material, makes the material easier to be broken from the defect.

More

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Diagram of a gyratory crusher [image: 135-5-16)] Gyratory Crushing Action. Designs of the breaking faces vary with manufacturer. As a result, the product size distribution varies. When the feed drops into the crusher, the mantle squeezes the rock against the concave surface.

More

(PDF) Modelling of Gyratory Crusher Liner Wear Using a

2023年10月30日 PDF A gyratory crusher is a key mineral processing asset in a comminution circuit. Monitoring and predicting the crusher liner wear is essential to ...

More

Torque Analysis of a Gyratory Crusher with the Discrete Element

2021年8月13日 A novel polar representation of the radial forces is proposed that may help designers, engineers, and operators to recognize the distribution of force loads on the mantle in an easier and intuitive way. Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely

More

Gyratory Crusher - Mining Fundamentals

A gyratory crusher is an ore processing machine that crushes the ore between an eccentrically mounted cone and a crushing throat that is fixed. In mining, the most important criteria for effective crushing of oresis to choose the type of crusher that suits the rock (ore) material and to ensure unifo. Skip to content. About;

More

Types of Crushers: What You Need to Know

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and

More

(PDF) Torque Analysis of a Gyratory Crusher with the

2021年8月13日 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power.

More

Torque Analysis of a Gyratory Crusher with the

2021年8月13日 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To

More

4 Types of Cone Crushers: What Are They and How to Select

2024年10月14日 In addition to the fixed cone crushers, many cone crusher models are also available as mobile versions. This type of cone crusher can be combined with the jaw crusher, vibrating screen, and other equipment to form a mobile crushing station. The crushing station has two types: crawler type and tire type. Learn more about the Mobile Crushing Station.

More

Torque Analysis of a Gyratory Crusher with the Discrete Element

2021年8月13日 A novel polar representation of the radial forces is proposed that may help designers, engineers, and operators to recognize the distribution of force loads on the mantle in an easier and intuitive way. Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely

More

Sandvik Gyratory Crushers CG800i - SRP

CG830i Gyratory crusher : 380 (419) 1,525 (60”) 2,700-6,000 (2,980 - 6,610) CG850i Gyratory crushers: 500 (550) 1,549 (61) 3,800-8,250 (4,180 - 9,075) The knowledge hub Over the last 150 years, we've learned a thing or two about crushing and screening.

More

Jaw Gyratory Crusher Pro - FLSmidth

The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.

More

Heavy duty, maintenance-friendly Gyratory Crusher - FLSmidth

The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components) and focuses on coupling these historical characteristics with updated maintenance-friendly features.

More

Gyratory Crusher TSUV

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this presentation from MINExpo 2021, Josh Garrett, Product Manager for Crushing, explains how all TS Gyratory Crushers are built for strength, durability and the ability to adapt to the various requirements of

More- concasseurs de pierres de granit a vendre

- business plan de carrire doc de business plan de carrire

- processus dans l xplosion de carrière de calcaire

- Nom Du Concasseur Giratoire De Capacité 3b20

- équipement de concassage en amérique du sud

- rectifieuse de vilebrequin de type mq

- prix de machines de construction

- usines de minerai de manganèse

- concasseur mobile pour utilisé de concassage de pierre vente

- concasseur pour l extraction de la chromite

- minerai de d'or broyeur marteaux 200 * 400

- séparateur magnétique de minerai de fer au sud afrika

- chinois pièces des concasseurs de 3 pieds

- séparateur magnétique humide mongolie à vendre

- jerman de concasseur mobile