primary crushing equipment for copper

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Copper Ore Crushing, Grinding Flotation - 911Metallurgist

2017年5月21日 The ore can be tested by proven techniques and crushers and mills selected with assurance that they will meet performance requirements. Operation of crushing plants,

More

Copper ore crushing equipment and beneficiation process

The large copper ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing; The coarsely crushed

More

Copper Ore Processing Plants, Flow And Equipment

2024年10月25日 Crushing process. The copper ore that needs to be processed must first go through the crushing process. The vibrating feeder is fed through the silo, and the vibrating feeder is evenly sent to the jaw crusher for

More

Copper Processing Plant - Shanghai Zenith Company

Copper ore in larger size will be fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing. After primary crushing, the material will transferred to cone crusher by belt conveyor for secondary

More

Copper Ore Crushing - SHANGHAI SANME MINING

In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing copper ore. Jaw crusher is usually used for primary crushing. Cone crusher is used for secondary and tertiary crushing.

More

Copper Introduction And Ore Crushing - JXSC Mineral

2024年6月13日 Copper Ore Crushing Equipment. Jaw crusher: Used for primary crushing and processing large pieces of ore. Single-cylinder hydraulic cone crusher: Suitable for medium crushing, processing harder ores, with a

More

Primary Crushers For Copper Ores

Primary crushers are machines used to break down large chunks of copper ore into smaller pieces that can be processed further. There are several types of primary crushers commonly

More

What crushing equipment is suitable for copper ore crushing and ...

1. Jaw crushers: Jaw crushers are ideal for primary crushing of copper ore, as they are designed to crush large blocks of material into smaller pieces. They work by applying high

More

How to Choose the Right Crushing and Grinding Equipment for

2024年10月12日 Primary Crushing Equipment. Jaw Crusher or Gyratory Crusher is usually chosen for initial size reduction ... Example: Copper ore processing often involves SAG mills for primary grinding, ...

More

primary crusher for copper production in chile

Primary Crushing Equipment For Copper How Mach. Primary crushing equipments for copper how mach the costosteffective crushing the combination of a nw106 primary jaw crushing plant processing copper ore with the equipment concept the price was right and the overall get price copper ore crushing machines feb 15 2016 the copper ore is to start with

More

copper ore primary crushing

Primary crushers for copper ore Primary crushing systems consist of crushers, feeders, dust control systems, and conveyors used to transport ore to coarse ore storage. jaw crusher, impact crusher, or gyratory crushers are usually used as primary crushers forcopper ore primary crushing Crushing and Grinding You will note that the Oracle Ridge

More

What Crusher Should You Choose for Primary Crushing?

2024年6月28日 Wide application: Suitable for both dry and wet crushing, for materials with up to 15% moisture. One-time forming: Eliminates the need for primary and secondary crushing, reducing costs by approximately 40%. Large feed opening: Handles feed sizes up to 1000 mm, making it ideal for coarse crushing. Non-clogging: Designed to ensure smooth flow of high

More

primary crushing of copper ore

primary crushing equipment for copper how mach the cost. 2021-5-25 Primary Crushing Mineral Processing amp Metallurgy. Feb 26 2016 The term primary crusher by definition might embrace any type and size of crushing machine The term implies that at least two stages of crushing are involved but in many cases the machine which performs the ...

More

Copper ore crushing equipment and beneficiation process

The copper ore processing and production process mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed-circuit crushing is more modern and suitable for high-hardness copper ore crushing, and can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency;...

More

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of the

More

Combining legacy and expertise Mining Crushing Stations - Metso

As the latest addition to the FIT™ family, the Metso primary gyratory station is designed for stationary primary crushing applications. Capacities range up to 4,000 tons per hour, 40 weeks (FCA) lead time and utilize our Superior™ MKIII crushing technology. The primary gyratory stations come in 3 different configurations: Single feed,

More

gold mining equipment jigger machine #jigging #machine #gold

Jingying Machinery is the factory with over 30 years experience for the stone crusher line (stationary crushing line or mobile crushig line).

More

Crushing and grinding production line equipment

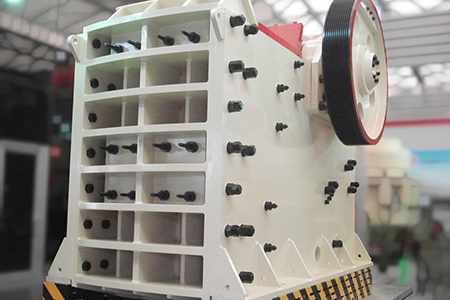

The beneficiation process typically involves crushing, grinding, and concentration stages. Crushing Equipment in Copper Ore Beneficiation. The first stage in the beneficiation of copper ore is crushing, which reduces the size of the ore particles and prepares them for further processing. The primary crushing equipment includes: 1. Jaw Crusher

More

Copper ore extraction and crushing equipment – Jaw crusher

Copper Ore Crushing. Primary Crushing: The first stage of crushing is carried out using a primary crusher. Jaw crushers are commonly used for this purpose. ... Crushing Equipment: Jaw Crushers: Characterized by their large, heavy-duty design, suitable for initial reduction of large ore chunks.

More

Copper Processing Plant, Equipment - JXSC Machinery

JXSC supports customized copper processing plant and equipment, fully suitable for separating copper oxide ... This setup is a complete rock copper processing plant, including crushing, grinding, gravity separation ... Free Flow

More

Looking For The Best Copper Ore Crushing Equipment For Your ...

The primary function of this equipment is to reduce the size of copper ore, making it easier to process and extract valuable minerals. High-quality crushers not only enhance the throughput of the concentrator but also improve the overall recovery rate of copper, leading to increased profitability for mining operations.

More

sbm/sbm primary crushing of cupper.md at main dihog/sbm

sbm primary crushing of cupperDefinition of primary crushing mindat glossary In ore dressing,the first stage in which crushers take run of mine ore and reduce it to a size small enough to be taken by the next crusher in the series.Ordinarily. Ore processing operations at Newmont Boddington Gold ...

More

what is primary crushing equipments

Crushing and screening equipment As we are manufacturing Sugar Plants, sponge iron plants and other heavy industrial equipments, We also manufacturing crushing and screening equipments. Range of Crushing Equipments ... Jaw crusher are designed for primary crushing of hard rocks with minimum rubbing action. This is achieved by incorporation of ...

More

1-20tph Mining PE 150X250 250X400 Used Diesel Engine Portable

Fine Crushing PE 150X250 PE 250X400 Diesel Engine Mobile Small Mini Stone Jaw Crusher Price for Ore Crushing Machine Equipment The jaw crusher outlet size can be adjusted, we can set the jaw plates gap size to get different products from 1/2 to 2 inches.

More

Crushing, Screening Conveying - 911Metallurgist

To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN; Use Add New Topic to ask a New Question/Discussion about Crushing.; OR Select a Topic that Interests you.; Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input.; Use Add Comment = to

More

Manganese ore crushing equipment processing technology

The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiation.During the crushing process, the three-stage closed-circuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding

More

Mineral primary crushing equipment – Metal Ore Crusher

Common types of primary crushing equipment include jaw crushers, gyratory crushers, and impact crushers. Jaw Crushers: Jaw crushers are among the most commonly used primary crushers in mineral processing. They operate on the principle of compressive force, where the material is crushed between a stationary plate and a moving plate.

More

Copper Ore Crushing, Grinding Flotation - 911Metallurgist

2017年5月21日 Operation of crushing plants, rod mills and ball mills is understood by many, and most operators are comfortable with the use of this type of equipment which has been around for over 70 years. Autogenous and semi-autogenous grinding is still quite new and mysterious to many, although there have been over 276,000 connected horsepower sold into

More- écraser et broyer des minerais métalliques

- représentant des ventes d équipements miniers en amérique latine

- concasseurs cotent tonnes par heure

- il est disponible pour toute subvention broyeur de pierres

- uk installation mobile de concassage

- machine de concassage de rembourrage de pipeline

- prix de concasseur à mâchoire dans kyrgyzstan

- 1100 650 concasseur à mâchoires zenith

- concasseur mchoire vendre en turquie

- combien de plante pierre concasseur a orissa

- liste des entreprises de donnees minières dans oman

- fabricant de l'usine de broyage de gypse thane

- i Dont web concasseur Seafight 2,51

- transformation du talc

- Usine d'enrichissement de minerai de fer�DXN