rock crusher produce

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

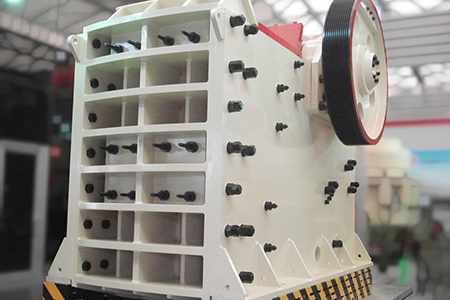

Types of Rock Crushers Quarry Crushing Equipment

However, you’ll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants. In compression crushing,

More

Crusher - Wikipedia

In industry, crushers are machines which use a metal surface to break or compress materials into small fractional chunks or denser masses. Throughout most of industrial history, the greater part of crushing and mining part of the process occurred under muscle power as the application of force concentrated in the tip of the miners pick or sledge hammer driven drill bit. Before explosives came into widespread use in bulk mining in the mid-nineteenth century, most initial ore crushin

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder. Crushers

More

Selecting the right crusher for your operations - Quarry

2020年3月19日 Cone crushers, which are also known for their ability to crush hard, abrasive ores and rocks, break material by squeezing or compressing it between convex and concave-shaped surfaces. Best suited for secondary

More

Crushers - Apache Ironworks

Our jaw is engineered to process up to50,000 psi rock in some of the most difficult applications. APACHE is among the heaviest jaw crushers on the market, size for size. When it comes to crushing hard rock weight, mass,

More

Cone crusher basics in 4 minutes - SRP

The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion. That is, it doesn’t remain completely centred – it swings

More

PRODUCTION WITH ROCKCRUSHER - Rokla GmbH Deutschland,

ROCKWHEEL cutting units enable you to work successfully with the lowest possible material and time input. Precise work in sewer and pipeline construction. ROCKSCREENER sieve

More

Crusher Rock: Exploring the Types of Rock Crushers

2024年6月28日 Crusher rock machines are designed to break down rocks into smaller, more manageable pieces. Different types of crusher rock offer various features and benefits for use in different industries. Consult experts when

More

Rock Crusher, Small Mobile Crusher - VYKIN Crushers

The small-sized Senya 3 MICRO Jaw Crusher is our entry level crusher and can produce 200-300 tons per day (realistically filling 1 dump truck per hour minimum). Our customer’s reported average ROI is 4 months with $225,000+

More

Rock Crushing 101: A Beginner's Guide Senya Crushers

High initial investment: For most aspiring rock crushers, the cost of purchasing a new rock crusher is one of the biggest barriers to entry. Look for a company like Senya Crushers that produces high-efficiency equipment at affordable prices

More

Cone crusher basics in 4 minutes - SRP

Feed moving towards a crusher in the Sandvik-designed Deer Park quarry in Melbourne, Australia. A quick spin. Are you aware of how fast the mantle in your cone crusher spins? It can make between four and seven revolutions per

More

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

More

Crusher Rock: Exploring the Types of Rock Crushers - Certified

2024年6月28日 A rock crusher reduces large rocks into smaller rocks, gravel, or rock dust. The mining and construction industries typically use these machines. They crush rocks into more manageable pieces and produce rock-fill material for landscaping and erosion control.

More

Crushers - All crusher types for your reduction needs - Metso

In many cases, dump trucks transport the rock to a stationary primary crusher. This may be an expensive solution. Amortization, fuel, tires, and maintenance costs can be included when the vehicles are in high demand. In modern aggregates operations, ... (while the reciprocating motion of the jaw crusher produces a batch crushing action).

More

Rock Crushers Pulverizers Williams Crusher

Williams Crusher has a variety of rock crushers to help you meet any size reduction need. What Type of Rock Crusher Do I Need? The type of rock crusher required depends on moisture content, the hardness of the material, and your desired product size. Crushing may take place in one process with a single crusher.

More

What Are the Differences Between The 7 Types of Crushers?

2024年7月15日 The outstanding feature of impact rock crusher is that it can fully utilize natural cleavage of material to produce a wonderful cubic product which is desirable for many of today's specifications. As a secondary crusher, HSI crusher can process material with a

More

Choosing the Right Rock Crusher - Lippmann-Milwaukee

2023年7月19日 Choosing the right rock crusher is crucial for efficient and effective rock crushing operations. Consider factors such as durability, ... Think about how many tons of material you need to crush daily and what rock crushers can produce those numbers. A too-small crusher will hold back the project ...

More

The Ultimate Guide to Rock Crushers - Mellott

2024年5月30日 Selecting the Right Rock Crusher Choosing the right rock crusher is crucial. It can make a significant difference in your operation’s efficiency and cost-effectiveness. The right crusher depends on your project’s needs. It also depends on the type and hardness of the material you’re crushing.

More

Crusher Rock: Exploring the Types of Rock Crushers

2024年6月28日 A rock crusher reduces large rocks into smaller rocks, gravel, or rock dust. The mining and construction industries typically use these machines. They crush rocks into more manageable pieces and produce rock

More

Mobile Crusher - Eastman Rock Crusher

Option 2. Medium hardness rock crushing ($70,000-150,000) Main equipment: jaw crusher, PF1210 impact crusher, 2YK1548 vibrating screen Applicable materials: limestone, granite, gypsum, marble, coal gangue, construction

More

Crusher Wear Parts – Rock Equipment

The crusher jaws produce better quality rock more consistently than standard original equipment jaws, while reducing the need for re-screening and re-crushing. ESCO offers a full range of options for all popular jaw crushers,

More

Rock Crusher (Railcraft) - Official Feed The Beast Wiki

This page is about the Rock Crusher added by Railcraft. For other uses, see Rock Crusher. The Rock Crusher is a multiblock structure added by Railcraft. This machine is used to process various items and blocks. This machine runs off of Redstone Flux (RF), using 16,000 RF/use, and takes up to 160 RF/t. At full power, an operation takes 5.005 seconds (as there is a 1 tick

More

Crushing Products Size and Shape -What to Expect

2016年2月26日 The Fairmount crusher is inherently a somewhat cleaner breaking machine than either the standard gyratory or standard jaw types, but the class of rock for which the former crusher is largely used is usually subject to greater than average degradation during the blasting and loading operations in the quarry, which tends to level out the difference in crushing

More

Portable Jaw Crushing Plant Senya 5 Senya Crushers

Discover the Senya 5 portable rock crusher jaw crusher from Senya Crushers. Perfect for on-the-go crushing, this powerful machine is a game-changer. Setup Service Videos (919) 323-4830 . Contact Us. Products. Micro Crushers. NEW! Senya 5 Portable Jaw Rock Crusher ...

More

VYKIN 8-JC Mobile Mini Tracked Jaw Crusher - VYKIN Crushers

Model: VYKIN 8-JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 0.26 – 0.52 gal/hr, 1.58 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 2-8 TPH Crushing material: softer-to-medium hard rocks — such as concrete, limestone, pavers, demolition waste, tile,

More

Crushers and Sieves - Titan Brick and Block Making Machines

Our company produces several types of crushers. ... characteristics, so we use several types of stone crushing units in order to crush them. In some cases, one type of crusher is enough for our equipment, ... one should use mills. If the size of the rocks is too large even for the first stage of processing, special rock splitters are used.

More

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Unlike grinding, which produces a fine powder, primary crushing produces larger pieces of material, which are then further broken down by the secondary and tertiary crushers. ... Choosing the right type of primary crusher for your operation depends on several factors, including the maximum size of the material to be crushed, ...

More

What Is Quarry Crusher - On-site Processing Stone, Rock, Granite

350TPH Stationary Quarry Rock Crusher Plant To Produce Aggregates in Honduras. The customer in Honduras owns a commercial concrete factory and previously sourced aggregates externally. With a newly acquired mining license, he plans to invest in a new crushing equipment setup to crushing granite at his quarry.

More- concasseur à cone concasseur à cone

- broyeur à boulets entreprise maroc

- Fabricant d usine d enrichissement du charbon en Inde

- densité apparente de la méthode m

- avec du marbre concasseur à machoires

- ultrasons brochure de la Sénégal de nettoyage

- Concasseur de gravier 745 tph Koweït

- 50 tph Congo concasseur à pierre

- la séparation de quartz de silice et de broyage

- pincement pour concasseur

- 2e concasseurs miniers de charbon a la main

- crusheres de pierres utilisés

- broyeur à cône de convoyeur à bande de convoyeur à bande de quai de machine de séparation magnétique

- entreprises pour concasseurs de pierre à mwanza en tanzanie

- machine de sable industriel