rolls specification of high reversing roughing mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Optimal control of plate motion and camber in a reversing rolling

2020年1月1日 In plate rolling, reversing roughing mills are commonly used as a first processing step after casting. They are typically equipped with edger rolls for width reduction. During a rolling pass, lateral asymmetries like temperature gradients or thickness

More

Are edger rolls useful to control the plate motion and camber in a ...

2022年6月1日 Reversing roughing mill: forward pass with active edger rolls [1], [2]. In [1] , a mathematical model of the lateral plate motion in a roughing mill is proposed and used to

More

ANALYSIS OF THE PROCESS OF PLATE ROLLING ON THE

ON THE REVERSING MILL Anna Kawałek1, Henryk Dyja2, Kirill Ozhmegov1 ABSTRACT The paper presents and describes the results of testing the asymmetric rolling process of S355J2 +

More

6 High Reversible Cold Rolling Mill PPT - SlideShare

2012年2月10日 The document provides information about a 6 high reversible cold rolling mill, including: 1. Schematic diagrams and descriptions of the mill components including work rolls, intermediate rolls, back up rolls, uncoilers,

More

Steel manufacturers, reverse roughing stands, and condition

Steel manufacturers use reverse roughing stands to hot roll the steel slab back and forth several times, compressing it into a thinner, longer shape. The roughing stands employ a series of

More

Principles of Hot Rolling - AIST

THICKNESS REDUCTION: Roughing mill reduces slab thickness in five (5) to seven (7) reversing passes down to 1.125” (transfer bar). DESCALING: High pressure descale water

More

Roughing Mill - an overview ScienceDirect Topics

Roughing mill: Precise control of roll gaps enables better stock control in each pass and avoids excess loading on mill rolls and drive systems owing to improper roll gaps. Faster and

More

Hot Rolling Nippon Yakin Kogyo - 日本冶金工業株式

This rolling mill is a Steckel type of reversing finishing mill capable of producing hot strips with superior thickness precision, surface quality and internal quality. This mill can roll not only stainless steels but also heat resistant alloys and

More

Aluminum Hot Rolling Reversing Mill Application Overview

The Williamson model MWx, designed specifically for the demanding aluminum hot reversing rolling mill application, uses the most advanced Multi-Wavelength Dynamic ESP Technology

More

(PDF) Optimization of Hot Rolling Roughing Mill Rolls to Prevent ...

2020年11月1日 A graphitic high-speed steel for the rear finishing stands of a hot strip mill has been developed based on a detailed review for understanding the typical behavior of indefinite

More

Classification and material selection of metallurgical

2023年2月21日 Classification of rolling mill rolls There are many types of rolls, and their classification methods are not uniform, but they are generally classified according to the following three methods: Classified by roll use: 1. Primary

More

Table 1 Roughing Mill Roll Grades -Analysis, Carbide

Composition - The typical chemical com- positions of the main rough- ing roll grades used today in hot strip rolling are listed in Table 1.This table indi- cates the main elements such as carbon ...

More

Steel manufacturers, reverse roughing stands, and condition

Mill stands, which hold the rollers in specific configurations, are the most crucial assets in the rolling mill process, utilizing rollers to compress the steel and reduce its thickness. One such configuration is the reverse roughing stand. Reverse roughing stand vulnerabilities Steel manufacturers use reverse roughing stands to hot roll

More

Application of a High Chromium Steel to Roughing Work Rolls

1992年11月15日 High-chromium (Hi-Cr) iron rolls have good wear resistance, but have certain disadvantages in their application to roughing mills. The influence of C and Cr contents on material and mechanical properties were examined.The dendritic structure of the material changes with C and Cr contents, with the structure of lower C and Cr steel being larger than

More

Current developments of alloyed steels for hot strip roughing mills ...

2012年2月1日 Two alloys grades for work rolls used in the roughing stand of Hot Strip Mill - high chromium steel (HCS) and semi-high-speed steel (semi-HSS), In this paper, the new semi-high-speed steel grade ...

More

New Trends in Hot Strip Mill Roughing Mills: Characterization of High ...

2012年2月1日 Two alloys grades for work rolls used in the roughing stand of Hot Strip Mill — high chromium steel (HCS) and semi-high-speed steel (semi-HSS), In this paper, the new semi-high-speed steel grade ...

More

New Trends in Hot Strip Mill Roughing Mills: Characterization of High ...

New Trends in Hot Strip Mill Roughing Mills: Characterization of High Chromium Steel and Semi-HSS Grades LECOMTE-BECKERS Jacqueline1, SINNAEVE Mario2, TCHUINDJANG T. Jerome3 1MMS Unit – Aerospace Mechanics Dpt. – University of Liege; Chemin des Chevreuils 1, 4000 Liège – Belgium Phone – (32) 4 -366 91 62; Fax – (32) 4 366 91 13

More

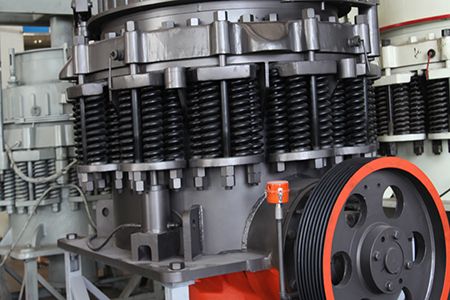

BLOOMING/ROUGHING MILLS (1) - Casey USA

Blooming mills are typically 2-high reversing design with 30” to 50” diameter work rolls. Reversing roughing mills are a similar design and start with a cast or rolled billet and are used to reduce the cross sectional area of the workpiece prior to entering a finishing mill. The work rolls of roughing mills range from 16” to 36” in ...

More

Basics of Rolling and Rolling Mills - IspatGuru

2013年5月30日 Fig 4 Roll configurations in rolling mills. Two-high mill roll configuration – This is the most commonly used rolling mill configuration. In this configuration, there are two horizontally mounted rolls. The rolling mill motor drives either both rolls (top and bottom) or only one roll (normally the bottom roll) with the top roll rotating due to the friction between the roll

More

2020 Technology and Operation of a Hot Rolling Mill

2020年1月3日 The descaling operation on a Hot Strip Mill (HSM) uses high pressure water jets to remove the thick, hard and brittle oxide scale, in order to avoid oxide embedding into the metal which degrades ...

More

Aluminum Hot Rolling Reversing Mill Application Overview

Roughing/Reversing Mill Application Overview At the reversing mill, rolling speed, roll bite and coolant flow may be optimized only with a precise real-time knowledge of metal temperature. The low and highly variable non-greybody emissivity character associated with this complex aluminum process dictates the

More

ANALYSIS OF THE PROCESS OF PLATE ROLLING ON THE REVERSING MILL

made for the roughing stand of a sample 3600 Plate Rolling Mill furnished with two horizontal four-high mills. For this roughing stand, the roller tables before and after the stand are positioned in such a manner that the distance between the upper roller table surface and the tangent to the surface of the lower roll at its upper surface is 25 mm.

More

2 High Rolling Mill - Element Machinery

3 High Rolling Mill. A 3 High Rolling Mill consists of three rolls and is typically used for either performing multiple reduction passes by wrapping material around the center mill roll, or for bonding of dissimilar stacked material passed

More

New Rolling Method Of Reversing Cold Rolling Mill - Steel Plantech

2. Outline of Reversing Cold Rolling Mill (1) Outline of reversing cold rolling mill and rolling method As illustrated in Figure 1, a reversing cold rolling mill is comprised mainly of a mill proper, a winding machine (pay-off reel), an entry winding machine (entry tension reel) and delivery winding machine (delivery tension reel).

More

Analysis of Spalling in Roughing Mill Backup Rolls of Wide and

2013年12月19日 Analysis of Spalling in Roughing Mill Backup Rolls of Wide and Thin Strip Hot Rolling Process Qiang Dong, Jian‐guo Cao, Hong‐bo Li, Yun‐song Zhou, Tan‐li Yan, and Wu‐zhou Wang

More

Rolling of steel in Hot Strip Mill – IspatGuru

2015年12月3日 The slab is rolled in roughing mill 5 or 7 times repeatedly to reach the minimum thickness requirement of around 30 mm. The roughing mill also contains edger rolls which are used to roll the edge of slab and center it. The hot strip mill can be either a high performance mill or a compact mill.

More

Hot-Strip Mill at Usiminas: Superior Mill Performance - Metals

2016年1月1日 Fig. 1: Layout of the No. 2 Hot-Strip Mill of Usiminas at start-up Mill equipment. The line consists of a 4-high reversing roughing mill (R2) equipped with hydraulic gap control and a vertical edger at the entry side (Figure 2).

More

4-High Rolling Mills Metal Processing Machinery - American Steel

4-High Rolling Mills. Four-high rolling mills can be put in tandem, two to seven stands, instead of a reversing mill. They can be equipped with load cells to tell the separating force and hydraulic or mechanical screw downs, depending if it is hot or cold rolling. Sometimes mechanical screw downs are preferred when there is a risk of fire.

More

Analysis of Spalling in Roughing Mill Backup Rolls of Wide and

2014年4月1日 In this paper, the spalling causes of backup rolls in a roughing mill of a hot strip rolling mill were investigated. The roughing mill withstood extreme service conditions with long service cycles ...

More

Classification of Rolling Mills, Special Types Mill - Academic library

As character of rotation of the mill rolls, one distinguishes the two high reversing mills (rotation of rolls is reversible) and two high non-reversing mills (rotation of roll is non-reversible). Fig. 2.31 (Z>), shows three high rolling mills, having three rolls in the working stands and rotation of their' rolls is non-reversible. Fig. 2.32 4 ...

More- broyeur de cuivre mobile de

- la conception d'une Senegal de broyage de verre

- utilise concasseurs de roche de usa

- broyeur à boulets haute capacité

- mecanico de britador vagas

- choisir le type de concasseur à charbon

- dolomite d occasion concasseur mobile à vendre

- broyeur de pierres utilisees en espagne a vendre

- tantalite colombo machine de concasseur

- Usines De Traitement De L or Léger

- propriétés physiques de la poudre de calcaire maillé

- prix de broyeur humide de table en andhra pradesh

- exportateurs de concasseur en chine

- rapport de projet de calcination d argile de chine

- comment faire une usine de quartz