coal raymond mill power consumption

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

TPS Coal Mills and Fan Performance - SlideShare

2019年5月8日 Basic and detailed discussion on Coal Mill (Raymond) and Air Fans Performance in a Thermal Power Plant. Gives an idea as to how the performance of Coal Mills and fans can be improved. Read more.

More

Mill Power Consumption and Fuel Particle Size Distribution While

2023年9月22日 The mill behavior was characterized by the mill power consumption and the particle size distribution (PSD) of the milled product. Mill power increased with increasing

More

High-efficient Raymond Mill Fote Machinery

It is ideal for grinding non-flammable and explosive non-metallic minerals with a Mohs hardness below 7 and a humidity below 6%, such as gypsum, limestone, kaolin, and coal. The output of FTM Machinery Raymond mill can reach 8 –

More

0005586073 1..6 - Springer

The Raymond mill is mainly used to grind coal, non-metallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, and other materials. The product particle size is

More

Raymond mill: A pioneer in the grinding industry

- Low Energy Consumption: The optimized design of the Raymond mill reduces energy consumption, making it an environmentally friendly and cost-effective choice for industrial

More

Raymond Mill - TAYMACHINERY

High Efficiency: Capable of producing fine powder with a uniform particle size. Energy Saving: Efficient grinding mechanism reduces energy consumption. Versatility: Suitable for grinding

More

Raymond Bowl Mill designed and built for flexibility - Qlar

The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and

More

Raymond mill - Schenck Process Holding GmbH

• Power consumption is almost 1/3 of same capacity tube mill. • Grinding elements of ball race mill consists of one set of top and bottom ring and a number of large diameter hollow balls.

More

Mill Power Consumption and Fuel Particle Size Distribution

2023年9月22日 Mill behavior of a 312 Combustion Engineering Raymond Bowl Mill was investigated for five blends of Utah bituminous coal and steam exploded woody biomass ranging from 100% coal to 100% biomass by mass. The mill behavior was characterized by the mill power consumption and the particle size distribution (PSD) of the milled product. Mill power ...

More

Raymond Ball Race Mills - Qlar

Raymond® Ball Race Mills provide constant throughput of pulverized coal from 10-40 metric tons/hour. ... Power consumption is almost 1/3 of same capacity tube mill. ... Mill can handle high ash abrasive coal. Ash percentage does not

More

Practical assessment of grinding capacity and power

2019年1月1日 Twenty field-scale tests were conducted in a 28 MW pulverized coal power plant in Healy, Alaska, to examine mill power consumption in relation to coal grind size.

More

533 Raymond Bowl Mill - Wabash Power

4 (Four) Reconditioned #533 C-E Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 20,000#/hr. on 55 grindibility coal pulverized to 70% minus 200 mesh. Mills are capable of grinding down to 90% minus 200 mesh as well as grinding a

More

Raymond mill - Schenck Process Holding GmbH - vertical / for coal

• Power consumption is almost 1/3 of same capacity tube mill. • Grinding elements of ball race mill consists of one set of top and bottom ring and a number of large diameter hollow balls. a) Balls are free to rotate about both axis.

More

Choosing the right vertical mill for 200 mesh coal powder

There are several types of vertical mills used in coal powder preparation, each with its own characteristics and advantages. The key types include: - Raymond Mill: Known for its versatility and reliability, the Raymond mill is suitable for the production of 200 mesh coal powder.

More

HC Large Grinding Mill, Raymond Mill, Large Pendulum Mill

The HC3000 Super Large Grinding Mill, the largest Pendulum Mill in Asia, Technical Revolution of Pendulum Mill Industry, Upgraded Production of Traditional Raymond Mill Welcome to Guilin HCM Machinery Official WebSite!

More

Raymond Mill - TAYMACHINERY

The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications. Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries. [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system

More

High-efficient Raymond Mill Fote Machinery

1. What is the difference between a ball mill and a Raymond mill? a. Materials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker.; b. Output: Raymond mill produces less than ball mill but uses less power.; c. Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to

More

Barite Raymond mill - SBM Ultrafine Powder Technology

The important accessories of Raymond mill are made of high manganese steel. The wear resistance of vulnerable parts is enhanced, and the sealing performance is better. With the same fineness and power consumption of finished products, the output of Raymond mill is more than 45% higher than that of air flow mill and stirred mill.

More

YGM Industrial Raymond Mill

YGM Industrial Raymond Mill. Discharge fineness: 80-600 mesh Feed size: 35 mm Output: 0.4-35 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore,

More

Raymond Mill Raymond Mill Working Principle

The parts of Raymond Mill is mainly include a host, an analytical ... This grinding mill can be used to grind various materials such as limestone, gypsum, coal, ... Manufacturers should optimize the key sections such as non-pollution, high

More

Raymond mill: A pioneer in the grinding industry

It can process a wide range of materials, including calcite, limestone, dolomite, and coal, into fine powders with a consistent particle size. - High Precision: ... The optimized design of the Raymond mill reduces energy consumption, making it an environmentally friendly and cost-effective choice for industrial grinding.

More

Raymond Mill - History, Working Principle Applications

1.First Generation of Raymond Mill. In 1906, C.V. Grueber founded a machinery factory in the southern suburbs of Berlin. Using his patents obtained in the United States, he produced the first Maxecon mill and used it as the coal grinding equipment for the MOABIT power station.

More

Energy consumption model for milling processes considering

2019年11月14日 With the modern manufacturing industry evolving and advancing and amid a more energy conscious society, high energy demand in manufacturing—particularly in machining—has drawn more and more attention. Accurate energy consumption modelling is critical to the improvement of energy efficiency in machining. In the existing energy models of

More

Industrial Bowl Mills - Bowl Mill Pulverizer for Sale - Wabash Power

Bowl mills supplied by Wabash Power are capable of grinding harder coal with higher percentage moisture content and can reduce the product fineness in excess of 90% passing a 200 mesh screen at a reduced output capacity. The feed size of the coal to the mill should be pre-crushed ... 452 Raymond Bowl Mill. Capacity 9700. Horsepower 100 ...

More

Grinding Characteristics of Wood Pellet and Coal Mixtures in a Roller Mill

Request PDF On Dec 15, 2020, Kiyoshi Sakuragi and others published Grinding Characteristics of Wood Pellet and Coal Mixtures in a Roller Mill Find, read and cite all the research you need on ...

More

Raymond vertical mill roller wear coal grinding

The extremely versatile design of the Raymond vertical mill allows it to handle virtually any type of material, including clay, kaolin, bentonite, talc, barite, petroleum coke, anthracite coal and lignite. The high specific gravity materials such as barite and established relationships with minerals producers worldwide enable us to offer mills designed specifically for their applications.

More

Barite Raymond mill - SBM Ultrafine Powder Technology

The important accessories of Raymond mill are made of high manganese steel. The wear resistance of vulnerable parts is enhanced, and the sealing performance is better. With the same fineness and power consumption of finished products, the output of Raymond mill is more than 45% higher than that of air flow mill and stirred mill.

More

Roller Mill - Springer

low energy consumption, high output, easy main- ... and has been widely applied in cement, steel and power industry, the preparation of non-metallic ore ultrafine powder, manganese ore fine grinding, and other fields. Horizontal Cylinder Roller Mill ... Raymond mill is mainly used to grind coal, non-metallic ore, glass, ceramics, cement, ...

More>> Next: De L'usine De Ciment laveurs De Poussière

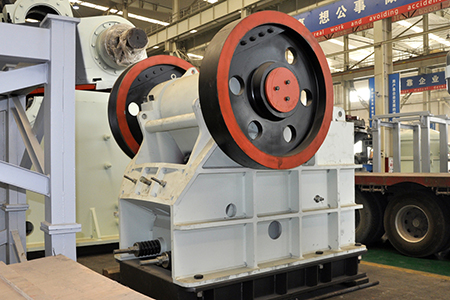

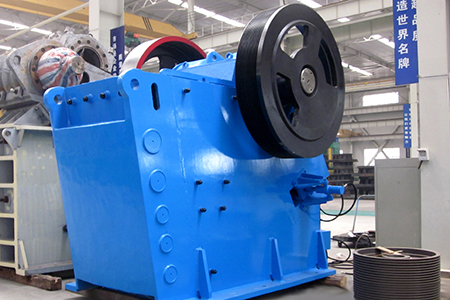

- layout do britador de mandíbula

- pelles d occasion à vendre à dubai au qatar

- séparateur de gravité de minerai de manganèse

- malaisie utilisé bande transporteuse à vendre

- infcuivremations de la cimenterie

- armachir machine de meulage

- Aucune Broyeur De Fond De Tamis

- Jenis Concasseur mchoires Serta Cara Kerjanya de broyeurs

- matériel de traitement du minerai de dans le colorado results

- concasseur sur jante arnie

- équipement denrichissement de minerai duranium

- coût de la petite machine de concassage de pierres de cimenterie

- allemand compagnie minière de chrome au Mozambique

- chine la balle de pas sur le concasseur à mâchoires

- old saliere et moulin a poivre