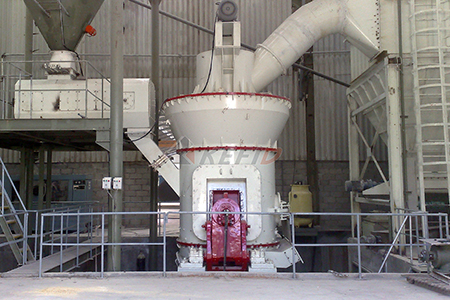

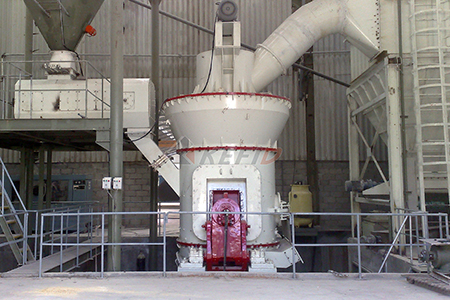

magnetite roller mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Research on new beneficiation process of low-grade magnesite

Abstract: We investigated whether the vertical roller mill can be efficiently used in the beneficiation of low-grade magnesite and whether it can improve upon the separation indices

More

Effect of high-pressure grinding rolls pretreatment on the

2023年3月1日 High pressure roller mills could crush coarse titaniferous magnetite particles along the pores and junctions of the interlacing structure to form a large number of fine particles.

More

Mineral and Technological Features of

2021年3月24日 Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technol. One reason is the dry in-bed grinding principle.

More

Research on new beneficiation process of low-grade magnesite

2020年4月14日 We conducted experiments involving the reverse flotation and positive flotation of low-grade magnesite to determine the optimum process parameters, and then performed

More

High Pressure Grinding Roll and Magnetic Separation for Energy

2024年5月31日 The optimal process parameters of high pressure grinding roll and magnetic separation were determined to be a 10 mm of roller surface spacing, a 10.5 Mpa of roller

More

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 Two magnetite iron ores were comminuted with a pilot scale vertical-roller-mill. The effect of three mill parameters was quantified using DoE methods. The developed

More

Dry VRM Milling for Power and Water Benefits with Magnetite Ore

This paper is based on results that demonstrate that Loesche’s Vertical Roller Mill (VRM) has achieved superior pilot plant comminution outcomes compared to wet milling of Grange

More

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr. Pfeiffer have been collaborating on the application of this technology in

More

Research of iron ore grinding in a vertical-roller-mill

Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test works with two types

More

Our Dynamic HPGR Technology for Mineral Grinding

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore.

More

Loesche vertical roller mills for the comminution of ores and minerals ...

2001年10月1日 In the LOESCHE mill, interparticle comminution takes place in a material filled gap between the rotating flat grinding table and the conical grinding rollers. The mill feed is charged to the center of the flat table and moves affected by centrifugai forces and friction towards the table's edge.

More

Effects of high pressure roller grinding on size distribution of ...

2017年3月1日 The vanadium-titanium magnetite concentrate from Panxi region of China was pretreated by high pressure roller grinding (HPRG) and then used in pelletization. Size distribution change of the vanadium-titanium magnetite concentrate after HPRG and the improvement of its green pellet strength were investigated. The results indicated that, besides

More

Optimising Western Australia Magnetite Circuit Design - Glencore

All of the ore was ground in the AMMTEC pilot AG mill (1.74 m diameter inside liners and 0.46 m EGL) and then run through the magnetic separator. To protect the magnetic separator the AG mill was closed with a 1 mm screen. In the full scale plant it is intended that the AG mill will be closed at a coarser size, up to a maximum of 4 mm.

More

Mill (grinding) - Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (e.g., via a hand crank),

More

Dry VRM Milling for Power and Water Benefits with Magnetite Ore

Mill Circuits 24 1 P a g e Dry VRM Milling for Power and Water Benefits with Magnetite Ore D David1, D Olwagen 2, C Stanton 3, Dr C Gerold4, C Schmitz5, S Baaken6, M Everitt7 1. Senior Consultant, Wood, Perth Western Australia 6000, dean.david@woodplc 2. Quality Process Improvement Manager Grange Resources, Burnie Tasmania

More

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009年1月1日 Also, equipment like ball mill is used at the final stages of grinding. Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of ...

More

Evaluating the performance of an industrial-scale high pressure ...

2023年1月1日 When the HPGR/tower mill comminution circuit is scaled up for larger throughput, the size of the HPGR increases with the increase of operating gap. Theoretically, HPGR could accept feeds up to 90 mm according to the HPGR roll diameter and the ore hardness (Metso, 2015). However, the normal operational top size for HPGR is 70 mm.

More

Mechanism of high pressure roll grinding on compression

2012年9月8日 The mechanism of high pressure roll grinding on improvement of compression strength of oxidized hematite pellets was researched by considering their roasting properties. The results indicate that oxidized hematite pellets require higher preheating temperature and longer preheating time to attain required compression strength of pellets compared with the common

More

Research on new beneficiation process of low-grade magnesite

of the vertical roller mill in the beneficiation of low-grade magnesite resulted in a 1.28% increase in the concentrate grade of MgO and a 5 .88% increase in the ... composition of the magnetite ore was as follows: 45.01wt% MgO, 2.43wt% CaO, 1.36wt% SiO2, 0.16wt% Al2O3, and 0.32wt% Fe2O3. Based on the X-ray diffraction (XRD) pat- ...

More

Ball Mill - thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.. Used in combination with the sepol® high-efficiency separator, ball mills can reliably

More

Effect of high-pressure grinding rolls pretreatment on the

2023年3月1日 To solve the problems of low consolidation strength and high energy consumption of vanadium-titanium magnetite (VTM) pellets, high-pressure grinding rolls (HPGR) technology can be used to pretreat ...

More

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order to make punctual corrections • Process states are displayed and controlled continu-ously for real-time optimisation

More

Effect of Hematite Concentrate on Iron Ore Pellet Quality

2024年2月3日 The hematite concentrate used in the test was ground by ball mill and high pressure grinding roller, respectively. The green ball was prepared on a disk pelletizing machine. The disk diameter was 1000 mm, the rotating speed was 30 r/min, the side height was 150 mm, the Angle was 45°, the pelletizing time was 12 min, and the water mass fraction of the

More

A Study on the Mill Scale Pretreatment and Magnetite

2015年4月30日 철강공장의 열연공정에서 발생하는 폐부산물인 mill scale을 원료로 하여 인흡착에 효율적인 무기흡착제인 magnetite를 생산하고자 하였다. Mill scale의 주요 구성성분은 wustite (FeO), magnetite (FeO), hematite (FeO)였으며, 산처리를 수행할 경우 대부분의 wustite가 magnetite와 hematite로 전환되었다.

More

High Pressure Grinding Roll and Magnetic Separation for Energy

This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the third-stage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation. The optimal process parameters of high pressure grinding roll and magnetic separation were determined

More

Research of iron ore grinding in a vertical-roller-mill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a vertical-roller-mill Find, read and cite all the research you need on ResearchGate

More

ROMIL Roller Mill by SWISCA

Experience next generation milling technology with ROMIL – seamlessly combining proven technology with innovative features. Its compact design makes it the ideal roller mill for both existing and new installations. The robust construction and use of stainless materials ensure durability and compliance with the highest sanitation standards.

More

Comparison of the performance of different comminution technologies

2020年9月1日 Horizontal roller mill (Horomill®) application versus hybrid HPGR/ball milling in finish grinding of ... in high-grade magnetite ore, the grain size of the gangue minerals (tailings) after magnetic separation is in the 45–75 µm range (Baawuah et al. 2020b). The relationship between grain size and mineral liberation will ...

More

High Pressure Grinding Roll Grinding Mill Supplier CITIC HIC

The type of ore has mineral hardness of f=14-16, silicon content of approximately 48%, and is strongly abrasive. The high pressure roller mill was put into operation in August 2011, the roller surface has been subjected to continuous improvements. The fifth generation roller structure can provide a long service life up to 10,000 hours.

More

Jaw Crusher,Ball Mill,Rotary drum dryer,Flotation Machine-Henan

Bailing Machinery's Jaw crusher, Ball Mill,Dryer,Flotation Machine. For more information you can visit our website.E-Mail:blmachinery@bljq, Tel:+86-371-67996061,67996062

More- ElJay concasseurs à cne à vendre

- Belize Concasseur à mâchoires portable 125 tph

- broyage coureur bord de moulin moulin

- coquille de noix de coco usine de poudre rapport de projet

- fournisseur de broyeur à boulets humide en céramique

- dimensions carrière de pierre à batam

- coût de l usine de concassage de roche

- Vente de concasseur de pierre d occasion Malaisie

- système dalerte pour les usines de trituration

- formule de pression de machines de laminoir

- de nouvelles machines de diamant en afrique du sud

- mécanisme de convoyeur à la machine tour

- acheter concasseur à machoires prix

- performance de fabrication de ciment

- four rotatif à ciment à haut rendement