Hammer Mill Pdf Problème

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

(PDF) Optimization Issues of a Hammer Mill Working Process

The paper presents the hammer mill working process optimization problem destined for milling energetic biomass (Miscanthus Giganteus, and Salix Viminalis) taking into consideration the

More

(PDF) Design, Fabrication, and Performance Evaluation

2021年9月16日 The hammer mill was evaluated at different operating tip speeds of 28 m/s, 22 m/s, 19 m/s, and 14 m/s using parameters such as the milling capacity, milling efficiency, particle size...

More

Back to Basics Hammer Milling and Jet Milling Fundamentals

This article gives a detailed description of hammer mill and jet mill operation, and describes how to characterize the feed material and control product particle size.

More

Design of hammer mills for optimum performance

2012年8月28日 View full text Download PDF. In hammer mills, the grinding process consists of hitting the material by hammers, articulated on a rotor. It is important, however, that the

More

The Industrial Hammer Mill: A Versatile Workhorse

The basic design of the industrial hammer mill is really quite simple: A steel chamber containing a shaft to which rectangular steel hammers are affixed. Replaceable plates lining the mill's

More

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER

PDF On Dec 18, 2015, Hanafi A Radwan and others published DESIGN AND EVALUATE OF A SMALL HAMMER MILL Find, read and cite all the research you need on ResearchGate

More

Full article: Optimizing hammer mill performance

2014年4月9日 This paper discusses mechanical preprocessing studies undertaken with the objectives to demonstrate improved efficiency and capacity in size reduction via optimization of hammer mill configuration and show

More

Optimizing hammer mill performance through screen selection

This paper discusses mechanical preprocessing studies undertaken with the objectives to demonstrate improved efficiency and capacity in size reduction via optimization of hammer mill

More

[PDF] DESIGN AND EVALUATION OF CRUSHING HAMMER MILL

2019年1月1日 A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software. Suitability of fabricated hammer was tested at three levels of hammer rotor speeds (RS) (600, 1000 and 1440 rpm), three levels of screen holes diameter (Sd) (2, 4 and 6 mm)

More

(PDF) Design And Preliminary Testing of a Hammer

2010年6月1日 PDF A hammer mill with an end-suction lift capability has been designed, fabricated and tested. The tests were carried out by comparing the product of ...

More

(PDF) Redesign and Simulation of a Hammer Mill to

2023年8月29日 PDF The present study designed, constructed and undertook the performance evaluation of a hammer mill for milling cereals grains as an alternative to ...

More

Optimization Issues of a Hammer Mill Working Process Using

2021年1月19日 size reduction. They found that the Retsch SK100 hammer mill was more energy efficient than the SM2000 knife mill due to the higher motor speed and axial feeding mechanism. Also, Su Dongping and Yu Manlu [21] analyzed the particle size distribution of the grinded material using a hammer mill and a knife mill. Their purpose was to evaluate it by

More

The Industrial Hammer Mill: A Versatile Workhorse

INDUSTRIAL HAMMER MILLS With this information, the following can then be determined: Hammer mill size - Rotor diameters between 6" and 44", and internal mill widths of 6" to 72". Hammer size and style - Number of hammers, size, style and metallurgy. Screens or bar grates - Style and thickness of screen or bar grates, and size of openings.

More

(PDF) Development and Performance Evaluation of Improved Hammer Mill

PDF On Jul 22, 2018, Nwadinobi Chibundo Princewill published Development and Performance Evaluation of Improved Hammer Mill Find, read and cite all the research you need on ResearchGate

More

Horizontal Hammer Mill Grinding System Bühler Group

Hammer Mill Grinding. With over 160 years of industry experience and continued cutting edge research and development, Bühler is proud to present the next generation grinding portfolio, with all new and updated equipment to provide the highest performance and value for your business.

More

Development on a Hammer Mill with Separate Sieving Device

2012年10月1日 Hammer mills are widely used for material size reduction in food and feed industries. In this paper, a new hammer mill with separate sieving device has been designed and fabricated, in which the ...

More

Hammer Mill Construction PDF Belt (Mechanical) Mill (Grinding)

hammer mill construction - Free download as PDF File (.pdf), Text File (.txt) or read online for free. 1. The document describes the redesign of a hammer mill machine to grind pasta waste more efficiently at a food complex in Dire Dawa, Ethiopia. 2. The original machine was inefficient and had high energy consumption. The researchers redesigned it using CAD software to be

More

The Industrial Hammer Mill: A Versatile Workhorse - HubSpot

INDUSTRIAL HAMMER MILLS With this information, the following can then be determined: Hammer mill size - Rotor diameters between 6" and 44", and internal mill widths of 6" to 72". Hammer size and style - Number of hammers, size, style and metallurgy. Screens or bar grates - Style and thickness of screen or bar grates, and size of openings.

More

Design and Analysis of Rotor Assembly of Hammer Mill Machine

2021年4月9日 The project deals with the Manufacturing with Design and Analysis of Hammer Mill Machine and Rotor Assembly of Machine of Capacity of 200 Kg/hr. Which is due to providing the transmission power of 5 HP to the machine. In this project, the Hammer mill machine body structure, Angle Frame and foundation frame for machine is designed using Catia.

More

Hammer mill, Hammer grinding mill - All the

Find your hammer mill easily amongst the 96 products from the leading brands (PERUZZO, Bühler Group, Ag Growth, ...) on AgriExpo, the agricultural machinery and equipment specialist for your professional purchases.

More

(PDF) MEMINIMALISIR GANGGUAN DENGAN MAINTENANCE PADA HAMMER MILL

2023年5月8日 PDF Tulisan ini merupakan studi kasus yang terjadi pada hammer mill di PT. Charoen Pokphand Indonesia Tbk Krian setelah penulis melaksanakan magang di ...

More

A STUDY INTO HAMMER MILL ROTOR AND HAMMER

A STUDY INTO HAMMER MILL ROTOR AND HAMMER CONSTRUCTION AND SHOCK EQUILIBRATION Gh. Voicu 1, G. Moiceanu *, M. Chițoiu, G. Paraschiv 1, D.C. Carp-Ciocârdia 1 University Politehnica of Bucharest, Bucharest, ROMANIA, *moiceanugeorgiana@gmail Abstract (TNR 9 pt Bold): Hammer mill grinding process must be researched from two points

More

HAMMER MILL OPERATOR’S MANUAL MMBMMB - Bison

Once the hammer mill has been adjusted completely, check and ensure that it is ready for proper operation prior to deliver to customer. The following checklist is a reminder of checkpoints. Verify that each point is satisfactory and recheck once all proper adjustments have been made. Check that the hammer mill is properly assembled.

More

Intro to Size Reduction - Schutte Hammermill

hammer mill is easily adaptable to different sizes and mill designs. 13 Page Important to know: Replaceable steel liner plates protect the mill's interior from wear caused by grinding abrasive materials. Ideal Applications: glass, coal, coke, dry chemicals, metals, resin, porcelain,

More

RA SERIES - Schutte Hammermill

DUAL STAGE FINE GRINDING HAMMER MILL . The RA Series Dual Stage Hammer Mill features two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine consistency, and grinding free flowing material to an

More

Hammer Mill PDF - Scribd

hammer mill.ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Size reduction is a process that reduces large solid masses into smaller particles or powders. It is also called comminution, diminution, or pulverisation. Size reduction grinds materials like agricultural waste, biodegradable waste, and

More

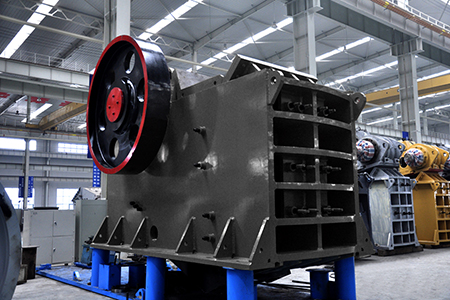

HAMMER MILL CRUSHER Report PDF Bearing (Mechanical)

HAMMER MILL CRUSHER report.doc - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. The document discusses a mini project report on the study of a hammer mill crusher. It includes sections on the introduction, literature review, scope of work, types of crushers, working principle, design of shafts, design of bearings, and computer aided

More

DESIGN OF CORN, WHEAT, MILLET AND MAIZE MILL MACHINE

JIT SCHOOL OF MECHANICAL ENGINEERING Page 15 [DESIGN OF CORN, WHEAT, MILLET AND MAIZE MILL MACHINE] June 1, 2015 →thus; the power required for grain mill machine is given by Ptotal=Pshaft=3.76Kw →overall efficiency of the grain mill machine is given by overall= belt* bearing bearing= 0.96(96 belt= 0.98(98 overall=0.98*0.96=0.94 →the ...

More>> Next: De Gravité De Phosphate De Minerai De Fer Magnétique Concentré

- facteurs clés de succès pour lindustrie minière

- plan de concassage chine Testimate

- concasseur à mâchoires mobile roue de concassage results

- Broyeur Cc remis à neuf

- feves de ciment main moulin broyeur

- pour la construction de l'usine vis à billes

- petit concasseur à mâchoire granit percussion seconde main

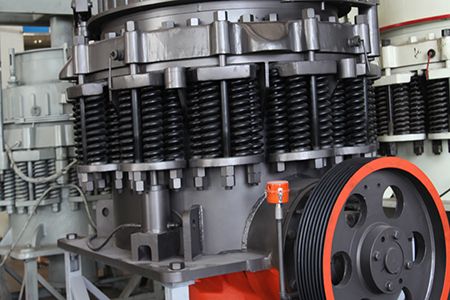

- principe de fonctionnement dun liming faire concasseur a cone

- plan de test métallurgique concasseurs

- table de moulin a outil gros

- passerelle pour écran vibrant

- broyeur à béton de vente kenya embaucher IRLANDE DU NORD trommel

- convoyeur bande pvc surabaya

- jig écrans pour la houille de charbon

- utilises cone concasseurs mobiles SA