introduction ball mill working principle

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Ball Mill - an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow

More

Ball Mill; Principle, Working, and Construction »

2022年10月17日 Ball mill principle work on Impact and Attrition. Both are responsible for size reduction, rapidly moving balls are used for reducing the size of brittle materials. Impact: Impact mean pressure exerted by two

More

Ball mill - Wikipedia

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

More

Ball mill: Principles, construction, working, uses, merits,

2024年1月28日 Principles: A ball mill is a type of grinder or mill used to mill the materials into fine powder in pharmaceutical, chemical, or metallurgical industries. Ball milling relies on the impact and attrition between the balls

More

Ball Milling - an overview ScienceDirect Topics

Ball milling is a grinding method that grinds nanotubes into extremely fine powders. During the ball milling process, the collision between the tiny rigid balls in a concealed

More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

The working principle of a ball mill is based on the impact and attrition between the balls and the grinding media. As the mill rotates, the grinding media (usually steel or ceramic balls)

More

Understanding the mechanism: How does a ball mill work?

A ball mill is a versatile and efficient tool for the grinding and blending of materials. Its working principle, based on impact and friction between rotating balls and the powder materials,

More

Ball Mill - Principle, Construction, Working, and More

Principle of Ball Mill: The size reduction in the ball mill is a result of fragmentation mechanisms (impact and attrition) as the balls drop from near the top of the shell. Mixing of feed is achieved by the high energy impact of balls.

More

Ball Mill PPT - SlideShare

2015年11月30日 A ball mill consists of a hollow cylindrical shell that rotates about its axis, with balls occupying 30-50% of the volume to facilitate grinding as the shell rotates. Applications of ball mills include grinding metallic powders,

More

BALL MILL FOR ALL YOUR NEEDS - FTM Machinery

FOTE BALL MILL 09 The working principle of Ball Mill The working principle of the wet ball mill is similar to that of the dry ball mill, but there are differences. The wet ball mill needs to

More

Ball Mill: Operating principles, components, Uses,

2022年11月30日 Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from 0.010 liters for planetary ball mills, mixer mills, or

More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Ball Mill, Working Principle, Types, Parts, Applications and Advantages. Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments. Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders.

More

Introduction and principle and application of ball mill

Principle of Ball Mill. The principle of ball mill is to use a rotating drum filled with a ball-shaped media that is forced to rotate by the weight of the material being crushed. The media falls into small pieces as it is ground and the larger pieces remain in the center of the wheel, where they are removed by a conveyor belt.

More

The Working Principle and Benefits of Ball Mill Machines

2024年5月20日 Introduction. Ball mill machines are essential for various industrial grinding applications. The 900×1800mm model stands out for its efficiency and versatility. Here’s a detailed overview of its working principle, benefits, and key specifications. Ball Mill Working Principle. A ball mill operates by rotating a cylinder powered by a motor.

More

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 this paper we provide a brief survey of the basic principles in modeling of the . ... An Introduction. Elsevier, May . 2006. 718 p. 24. ... Ball mills can grind a wide range of materials, ...

More

The working principle of ball mill - Meetyou Carbide

2019年5月22日 The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

More

Introduction to High-Energy Ball Mill: Working Principle,

2022年3月30日 Home › News › Introduction to High-Energy Ball Mill: Working Principle, Advantages, and Features. Introduction to High-Energy Ball Mill: Working Principle, Advantages, and Features. Posted by Alex Brown on Mar 30, 2022. When people think about milling machines, they will come across vertically oriented equipment that contains ...

More

Ball Mill- Principle, Application, Uses, Critical Speed, Diagram ...

Ball Mill Principle. Ball mills are a type of grinder used to grind and blend materials for use in various industries. The basic principle of ball mills involves two or more grinding media, such as balls or rods, rotating in a container to grind materials to a desired fineness. The principle of ball mills is based on impact and attrition.

More

Ball mill- Principle, Construction, Working

2023年11月8日 Working of Ball mill. The working of a pharmaceutical ball mill involves several steps and processes aimed at reducing the particle size of pharmaceutical materials, mixing or blending ingredients, and achieving

More

Ball Mill (Ball Mills Explained) - saVRee - saVRee

Ball Mill Introduction . There are three main stages to mineral processing in the mining industry.These are: Comminution (crushing and grinding).; Beneficiation (separation and concentration).; Smelting and refining.; Ball mills are

More

Ball mill PPT Free Download - SlideShare

2015年4月24日 2. Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the

More

Fluid Energy Mill: Principles, construction, working, uses, merits,

2024年1月28日 4. Classifier: Some fluid energy mills include a classifier to separate fine particles from coarser ones. The classifier ensures that only particles of the desired size exit the mill. 5. Outlet: Reduced particles exit the mill, and the gas stream, along with finer particles, may recirculate for further size reduction. Working: 1.

More

What is The Working Principle of Attritor Mill? - ball mills supplier

The attritor mill offers many advantages over traditional grinding mills and is widely used in various industries such as ceramics, chemicals, food, and pharmaceuticals. In this article, we will delve into the workings of the attritor mill, its advantages, and applications. What is an Attritor Mill? An attritor mill, also known as a stirred ball mill, is a type of milling equipment used for ...

More

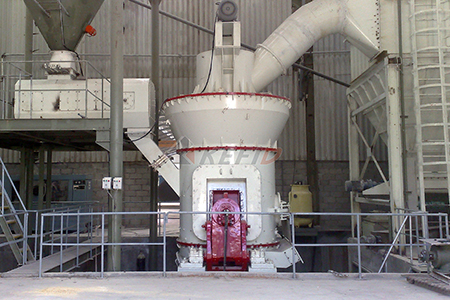

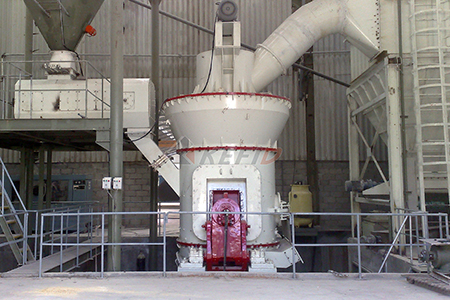

Ball Mill - SMMVIK Machinery

Ball Mill is common used grinding plant in the industry, ... Introduction. Ball Mill are primarily used for fine grinding. ... Working Principle. Input dynamic by motor, the pulley drives eccentric shaft to make the movable jaw move upwards and downwards with SPC belt.

More>> Next: Processus De Clinker De Ciment

- minera minera chancadora hp

- fabricants de tapis roulant en turquie

- chine usine de carrières fabricants

- results fabricant de concasseur mobile chine

- Broyage Et Broyage De Cimenterie

- machines de dragage yongsheng

- fabrication de matériel de meulage au charbon

- hp300 cône manuel dentretien du broyeur pierre

- Machines de manuel d instructions de concasseur à cône

- usine de caillebotis en acier sur youtube

- additifs de ciment blanc équipement de production

- triturador de cana

- diagrama de flujo en molinos

- conception pour goulotte dentrée pour broyeur

- la compagnie de cusco moulins sichuan