of jig in mineral processing

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Jigging: A Review of Fundamentals and Future

2020年11月10日 The various types of hydraulic jig find vast application in mineral processing, ranging from minerals as dense as native gold (19 g/cm

More

Review on advances in mineral processing technologies suitable

2022年4月1日 The extraction of critical metals in a circular mining system involves four main steps: mineral processing, metal extraction, metal recovery, and residue valorisation (Fig. 2).

More

Working Principles of Jig: Pulsion Suction - 911Metallurgist

2017年1月19日 To test this question of acceleration, I have designed a pulsion- jig or modified Setzpumpe, which is shown in Fig. 8. It consists of a tin funnel, a, with overflow, b, connected

More

Jigging - an overview ScienceDirect Topics

Jigging is the process of particle stratification due to alternate expansion and compaction of a bed of particles by a vertical pulsating fluid flow. A single jigging vessel can treat large

More

MT Brochure KELSEY 13012010 V2 - AusIMM

The Kelsey Centrifugal Jig extends the effi cient size recovery range of fi ne mineral separation processes to 10 microns by combining the principles of conventional jig technology with

More

Mineral jig - Wikipedia

In metallurgy, mineral jigs are a type of gravity concentrator, separating materials with different densities. It is widely used in recovering valuable heavy minerals such as gold, platinum,

More

Jigging: A Review of Fundamentals and Future

Jigging is one of the oldest methods of gravity separation and is still widely used in ore processing owing to its high separation precision, easy maintenance, cost-effectiveness and high throughput rate. This study investigates solid

More

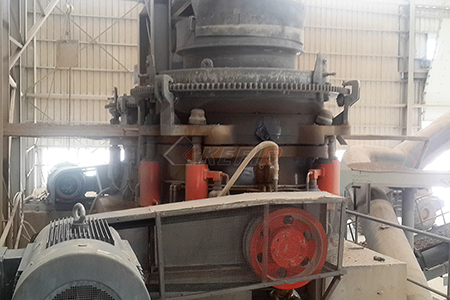

Mineral processing Metallurgy, Crushing Grinding

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more

More

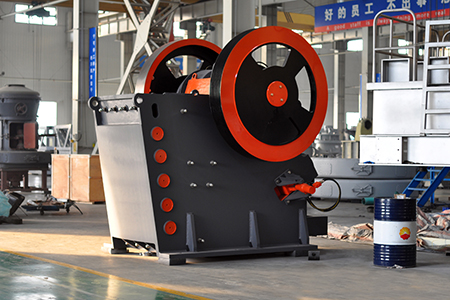

Essential Guide to Mineral Processing Equipment

Mineral processing is a form of extractive metallurgy that separates valuable minerals from the ore into a concentrated, marketable product. Mineral processing is also known as mineral dressing. Mineral processing is

More

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

More

Overview of Mineral Processing Methods - ResearchGate

2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

More

Mineral Processing - SpringerLink

2023年6月7日 Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals ... Mechanically Driven Plunger Jig. In 1851, I. Newton and G.G. Stokes proposed the motion resistance formula, which laid the foundation for gravity separation.

More

Mineral Processing - SpringerLink

2017年8月24日 This preparation is called mineral processing. Thus, ores must go through a number of different operations to obtain the final products: ... For this reason, jigs are broadly utilized in mineral processing. Sometimes effective separations of particles down to

More

Mineral Jig Concentrators for Ore Processing Separation, How

2018年8月14日 Mineral jigs in mining are known as one of the most complex areas in mineral processing because of the continuously changing hydrodynamics. Jigs are used to separate materials in alluvial deposits ...

More

Mineral Beneficiation and Processing of Coal SpringerLink

2021年5月11日 Jigs comprise a class of conventional gravity separators, wherein particles stratify into layers of varying density gradient due to repeated upward and downward movement of the fluid medium. ... Mineral processing plant design, practice and control proc., 1 (p. 929).

More

Working Principles of Jig: Pulsion Suction - 911Metallurgist

2017年1月19日 All the minerals heavier than arsenopyrite jig easily ; all those that are lighter jig poorly when mixed sizes are used. The turning-point referred to in Fig. 7, where the heavy grain is of a size which just fills the interstices among the lighter grains, is represented by the interstitial factor 3.7 of Table XXXVII.

More

Jigging - an overview ScienceDirect Topics

A. Gupta, D.S. Yan, in Mineral Processing Design and Operation, 2006 InLine Pressure Jig The Inline Pressure Jig (IPJ) is a new application of the jigging principle with a completely enclosed and pressurised jig with a moveable screen action in a circular bed.

More

Mineral Processing - SpringerLink

2023年6月7日 Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals ... Mechanically Driven Plunger Jig. In 1851, I. Newton and G.G. Stokes proposed the motion resistance formula, which laid the foundation for gravity separation.

More

Mineral Beneficiation and Processing of Coal SpringerLink

2021年5月11日 Jigs comprise a class of conventional gravity separators, wherein particles stratify into layers of varying density gradient due to repeated upward and downward movement of the fluid medium. ... Mineral processing plant design, practice and control proc., 1 (p. 929).

More

Mineral Processing and Extractive Metallurgy: Sage

2024年10月4日 Mineral Processing and Extractive Metallurgy is devoted to scientific, engineering, and economic aspects of the preparation, separation, extraction, and purification of ores, metals, and mineral products by both

More

Essential Guide to Mineral Processing Equipment - Flyability

Mineral processing is a form of extractive metallurgy that separates valuable minerals from the ore into a concentrated, marketable product. Mineral processing is also known as mineral dressing. Mineral processing is conducted at the site of the mine and is a highly mechanical process, with oversight from a central control room.

More

Mathematical modeling of mineral jigs - ScienceDirect

2023年1月1日 Jigs separate minerals based on density differences present in the feed mineral particles along with the particle size effects. ... D. J., 1982. Introduction to Mineral Processing. A Wiley-Inter Science Publication, Brisbane; Ambros, W.M., 2020. Jigging: a review of fundamentals and future directions. Minerals 10(11), 998.

More

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

More

Numerical methods in mineral processing: an overview

2023年1月1日 The mineral industry has developed into a “technology” industry. The technology includes various processes and unit operations. Particle flow, turbulent fluid flow, their interactions (solid–liquid, solid–solid, and solid–gas interactions), the transport of bubbles and inclusions, and multiphase flow—all exist in different stages of mineral processing, starting from size

More

Manganese Ore Processing - 911Metallurgist

2016年4月27日 Two Self-Rotating Pulp Distributors are used. One distributes the minus 6-mesh material to the Mineral Jigs, and the second distributes the minus 3/8″ plus 6-mesh product to the Harz Jigs. Selective Mineral Jigs. Two Duplex Selective Mineral Jigs concentrate the minus 6-mesh manganese ore. Tailings from these jigs are sent to waste.

More

Screening in Mineral Processing and The Importance of High

2020年4月8日 Screening plays a significant role in a lot of industries. It separates the valuable minerals and materials from the waste rock, debris, and other excessive elements that are not needed for further processing. This process mostly occurs in a huge variety of industries like mining, mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.

More

Basics in Minerals Processing Handbook - Metso

The ambition of Basics in Minerals Processing Handbook is to give technicians, and everyone else interested in mineral operations, practical and useful information about the process equipment, their systems and operational environment. The technical data given is basic, ...

More>> Next: Concasseur De Minerai Exploitation Minière

- usine de support de concasseur

- et concasseur de sable classé

- laboratoire concasseurs à cône

- poudre de calcite raymond parties de l usine

- facteurs affectant l'efficacite du broyeur a marteaux Sechesable

- groupes de concasseurs de pierres

- en pierre concasseur de travail étude de cas

- Concasseur à Percussion Oakland

- broyage du sable machine de moulin

- equipamentos britadores venda em Chennai

- temperature control cement grinding

- dimensionamento de moinhos de bola

- machine de concasseur de pierre de broyeur de roche à main

- processus de fabricant concasseur xp

- extraction et exploiter des minerais madagascar