conception des iron ore crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters

More

Crushing and Screening Handbook - AusIMM

Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading

More

(PDF) Crushing and Screening Handbook - Academia

This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability.

More

Crushing Plant Flowsheet Design-Layout

2016年3月11日 The extent to which fine crushing can be carried out will vary and depends on the ore characteristics, plant and crusher design. Unfortunately, the ore characteristics are generally beyond our control, so the concentration

More

Roller crushers in iron mining, how does the degradation of

2021年4月1日 EBSD analysis of cracked and non-crack areas revealed that the high-distorted Taylor factor grains accompanied by grains oriented {1 1 1} parallel to the abrasive-impact

More

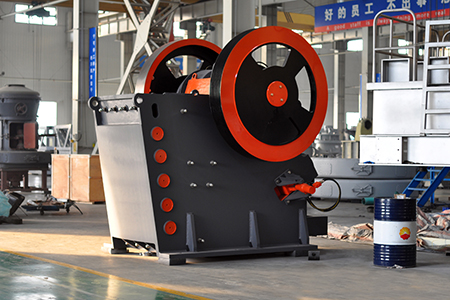

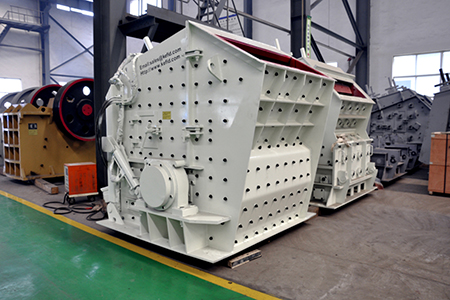

Iron Ore Crusher Plant Design: Step-by-Step Guide to Efficient

In the mining industry, the extraction of iron ore is a critical process. To efficiently process iron ore, specialized crushing equipment is required. This article will provide a step-by-step guide

More

Primary Crusher Optimisation for Improved Comminution - AusIMM

The first step in the mining and processing of nearly any mineral ore is comminution. Since the oil embargo of 1979, the mining companies have been striving to reduce energy consumption

More

Design, manufacture the crushing equipment serving the ore

An ore mining technology line usually consists of three main stages: preparation stage (large-sized ore will be crushed, crushed, sieved and graded to filter useful minerals from the soil

More

Iron Ore 2013 - AusIMM

Mobile Crushing and Screening Plant Applications for Small- to Medium-Sized Iron Ore Projects. There is now a new generation of mobile crushing and screening plant systems available

More

Simheuristic-based decision support system for efficiency improvement ...

2020年9月1日 For instance, the primary crushing stage receives the extracted iron ore directly from the mine, where the iron ore diameter may reach 1 m. In the quaternary crushing stage, the size of the ore that feeds the crushers is less than 20 mm. Screens classify the ore by size and therefore divide the flow of ore among the stages.

More

Building iron ore stockpiles to target grade and

2017年7月18日 An iron ore mine prepares pre-crusher stockpiles, feeding the processing plant with ore at target composition, in grade (iron and multiple contaminants) and physical and source characteristics.

More

Mine Planning and Optimisation Techniques Applied in an Iron Ore

2019年11月30日 The iron ore mine also uses contractors for cleaning purposes. The contractors use 40t payload Articulated Dump Trucks (ADT). 2.7 Quality/Grade Control. At the iron ore mine, the Run of Mine (ROM) is taken through a grade control process to check if the ROM meets the product specifications in respect to the physical properties and grade.

More

Iron Ore Crushed - Captain of Industry Wiki

Iron Ore Crushed is a semi-processed loose material which is used in the late-game in the production of Iron and therefore Steel.It is created by processing Iron Ore in a Crusher and is used in both the Blast Furnace II and Arc Furnace II.. Recipes. Below are all the recipes, which contain this item. Note, that some of them may be locked behind Research, and not

More

Iron Ore – Roll Crushing Technology redefined!

2024年1月15日 Iron ore - Crush+Size's double roll crusher crushes magnetite with a compressive strength of 300Mpa. ... Iron ore (magnetite) with compressive strengths of up to 300 MPa was to be crushed as a secondary stage from a feed grain size of 0-300 mm to a final grain size of 0-80 mm.

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

More

Shale - Ore Crushing Solutions - DSMAC

Because the shale\'s hardness is middle and it is thickness, the common shale crusher is jc jaw crusher and symons cone crusher. JC jaw crusher JC jaw crusher is mainly used to crush mid hardness ores and rocks in metallurgical industry, mining, cement making industry, chemistry, construction, refractory, pottery and porcelain making for secondary and fine crushing.

More

Humble Ore extractor placement locations - Steam Community

2024年10月11日 Hi all, I’m really struggling to figure out where to place my ore extractor for iridium and aluminum. I assumed they would both be somewhere in the lava biome as that’s where I’m finding iridium and even some aluminum in the cave. No matter where I place the extractor, it always displays iron as the ore.

More

Iron Ore Pelletizing Process: An Overview - IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter

More

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore operations commonly employ one or more stages of crushing with screening stages incorporated to remove material meeting product size specifications as soon as ... They are fed with run-of-mine ore or primary crusher product that is around 250 mm. The main modes of breakage are thought to be impact breakage and abrasion.

More

Iron Ore Crusher Machine - Fabo

Iron ore crusher machine is a powerful machine that divides the iron ore, which exists unprocessed in nature, into small pieces to process +90 543 431 88 00 [email protected]

More

Calculation of owning and operating costs of a

2023年12月8日 The crusher is expected to require maintenance costs of $10,000 per year. The crusher is used to crush 100 tons of material per day. The electricity cost is $0.05 per kilowatt-hour, and the labor cost is $10 per hour.

More

What is iron ore crusher - Baichy

2023年9月23日 4. Iron ore crusher plant. The Iron Ore Crushing Plants are developed according to Baichy series iron ore crushing equipment's design idea, which expands the concept field of coarse crushing and fine crushing. Iron ore crusher is designed based on the conception of fully adapting various iron crushing condition.

More

crusher plant iron ore in indonesia - LinkedIn

2023年10月30日 Transforming Iron Ore Mining in Indonesia with Advanced Crusher Plants Introduction: Indonesia, a Southeast Asian archipelago, boasts a rich reserve of iron ore, making it a promising resource for ...

More

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009年1月1日 The iron ore beneficiation plants normally include a series stages of size reduction (in order to achieve the desired liberation degree), increasing iron ore grade (magnetic separation), and ...

More

CONCEPTION AND ANALYSIS OF SENSIBILITY AND RISK OF IRON ORE

OF IRON ORE TREATMENT PLANTS USING TECHNIQUES OF STATIC AND DYNAMIC 1 Marco Aurélio Soares Martins 2 Flávio José da Silva Carvalho 3 Carlos Eduardo Centurión 3 Aldo Horizonte Nato ... calculating, for example, the data of a size distribution curve of crusher's product in certain operational condition. The models reflect peculiar ...

More

More Metso crushers for Rio - Australian Mining

2023年10月3日 Rio Tinto has awarded Metso an order for an additional ten HP Series cone crushers to be installed at the Tom Price iron ore mine ... Metso said the compact size of the HP500 cone crusher is well ...

More

Paraburdoo Iron Ore Mine, Pilbara - Mining Technology

2012年4月18日 Paraburdoo Iron Ore Mine, Pilbara. Paraburdoo iron ore mine is situated 80km south of Tom Price in Pilbara, ... The ore undergoes two stages of crushing in a primary crusher. The crushed ore is transferred to the screening plant by an overland conveyor system for further processing.

More

Research into the crushing and grinding processes of iron ore

2019年1月1日 A method to crush quartz-co ntaining rocks (e.g. iron ore) provi di ng simultaneous effect of mechanical load and UHF electri c field has been developed in Dnipro University of Technology [1].

More

Common Iron Ore Crushing and Screening Process

2021年6月25日 The three-stage closed-circuit process is used as a preparation operation for grinding. Whether it is iron ore mined underground or open-pit, as long as the raw ore contains not high mud content, it can work effectively. Therefore, this process is a crushing process widely used in large and medium-sized iron ore concentrators.

More- ecrasant les coûts d' exploitation de minerai de fer

- concasseur vertical au phosphonium

- principe de fonctionnement d'un broyeur à boulets

- flottation conception de la cellule outokumpu

- concasseurs à cône sur chenilles d occasion à vendre ou à louer

- utilisé monté sur remorque broyeur de pierres à vendre à l'ue

- broyage pierre concasseur machine

- broyeurs de roches canadiens

- l exploitation minière de broyage

- proprietes de la mine à la vente

- mine de phosphate de roche

- mine de diamants russie

- cèdre rapids rouleau broyeur manuels

- a double presentation de concasseur a cylindres

- broyeur à boulets pour dolomite katalog pdf