working working of raw mill in cement plant pdf

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Vertical roller mill for raw Application p rocess materials

The basic management of the components of cement raw materials is to set the mixing ratio target based on the chemical composition of various raw materials and feed back the results

More

The Cement Plant Operations Handbook - International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide.

More

(PDF) Cement plant operation handbook - Academia

Download Free PDF. Download Free PDF. Cement plant operation handbook. jorge pinedo sanchez. See full PDF download Download PDF. Related papers. ... waste heat from both pre-heater and clinker cooler exhaust gases to produce

More

Study of Processing and Machinery in Cement Industry

A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement. Dry raw mills are the normal technology installed today, allowing minimization of

More

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

As a result, our plants work efficiently without any trouble. » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single

More

Cement Plant: The Manufacturing Process 4 5 - World Cement

consumers The crushed limestone and aggregates such as sand, clay and ironstone are blended together in a raw mill to a particle size of 90 micrometres, producing “kiln feed”.

More

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Abstract - Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling. The process simulation

More

BALL MILLS Ball mill optimisation - Holzinger Consulting

common solution to grind raw materials and cement. Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding

More

Cement Plant Operations Handbook 5 - Advertisers Preview

Cement Plant Operations Handbook 5th Edition 15 Contents SAMPLEProcess Summaries 1. Introduction 20 2. Raw Materials 23 1. Raw Materials – 2. Reserves – 3. Crushing – 4. Pre

More

A practical guide to improving cement manufacturing processes

Raw mill kiln Tips for Improvement 1. Belt scale systems proportionally feed materials to the raw mill to ensure the correct “blend”. 2. Conveyor protection switches help prevent accidents

More

Cement Manufacturing PDF Cement Mill (Grinding)

cement manufacturing PPT - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document summarizes the cement manufacturing process used by Mangalam

More

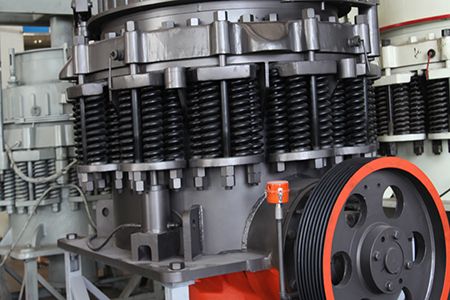

Coal Mill In Cement Plant, Air-swept Coal Mill Coal

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coal.It is the important auxiliary equipment of

More

Summer tranning report at jk cement works ltd PDF

2018年10月8日 Summer tranning report at jk cement works ltd - Download as a PDF or view online for free. ... Preheater Kiln Cement mill Packing plant 18. Page ... Figure 3.8 Working Principle of Raw Mill 3.1.5.1 Working Principal

More

Ball Mill In Cement Plant - Cement Ball Mill AGICO Cement

Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the open-circuit ball mill is only 1/2-1/3 of that in the closed-circuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and unsatisfactory enterprise benefits.

More

ESP Electrostatic Precipitator - Cement Plant

AGICO CEMENT supplies esp electrostatic precipitator (electrostatic dust collector) and other related cement plant equipment, FREE Quotation now! Skip to content +86 13683722138. info@cement ... Raw Mill; Vertical raw mill; Disc pelletizer; Clinker Production. Cement kiln; ... Here is a FREE spare parts PDF for you! Download it now if you have ...

More

(PDF) Thermodynamic Analysis of Raw Mill in Cement Industry

IOSR JOURNALS, 2019. Several studies were already carried out on the efficient use of energy in the past but little was done so far on the comparative study of energy and exergy for some manufacturing processes.To this effect, in this study, the compilation and analysis of data collected from a cement manufacturing plant in the North-Central region of Nigeriafor a period

More

Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw Mill

AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System. Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants.Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important

More

classifications and working of mills in a power plant PPT

2020年6月29日 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill. If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube mill.

More

fr/45/rawmill in cement plant pdf.md at main hongyib/fr

Host and manage packages Security. Find and fix vulnerabilities

More

Plant Maintenance Modelling Through Availability Analysis In Raw Mill

2020年12月29日 Maintenance activities are a particular concerned at PT XYZ, which is the largest cement producer in Eastern Indonesia. PT XYZ has five main factories located in Pangkep, South Sulawesi, units 1,2 ...

More

OK™ mill The most reliable and efficient mill for raw and cement

The OK™ mill has been FLSmidth’s standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation. In 2017, FLSmidth introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement ...

More

(PDF) Mass Balance Reconciliation for Bilinear Systems: A Case

2016, Mass Balance Reconciliation for Bilinear Systems: A Case Study of a Raw Mill Separator in a Typical Moroccan Cement Plant In order to simultaneously reconcile flow and composition measurements in this circuit, the component mass balances was included as constraints which contain the products of flow rate and composition variables in the data reconciliation problem.

More

Study of Processing and Machinery in Cement Industry

3. Raw mill: The conveyors collect the raw material (low or high grade), additives and transfer it to raw mill. This raw mill consists of 3 Raw mill grinding media Dry chamber Dry raw mills are the normal technology installed today, allowing minimization of

More

The digitization work of cement plant in China - ScienceDirect

2023年11月1日 In recent years, China's cement industry has always taken reducing carbon emissions as its core goal, studied the carbon emission factors of cement process through intelligent means, and explored the carbon peak and carbon neutralization path of cement industry [15].With the increasingly stable cement production, the demand for high-quality

More

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from... Find, read and cite all the research ...

More

Coal Mill In Cement Plant, Air-swept Coal Mill Coal Mill

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coal.It is the important auxiliary equipment of pulverized coal furnace. The air-swept coal mill runs reliably, can work continuously, also has a large production capacity and less energy

More

Raw milling and blending - INFINITY FOR CEMENT EQUIPMENT

The main difference to cement mill operation is the need to dry rawfeed and assure transport of stightly moist materialwithin a mill. ... (201312) describe a plant trialusing an extremely-coarse raw mix, following laboratory tests in which calcareous raw materialwas ground more coarsely. A major gain in mill output was achieved, ...

More

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 The study indicates that for a dry type cement production process, the carbon dioxide emission intensity for kiln feed preparation process is about 5.4 kg CO 2 per ton cement produced. In this study, the raw mill of a cement plant is considered and its performance based on the first and second laws of thermodynamics is investigated.

More

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 PDF The paper presents ... The mill is driven by a girth gear bolted to the shell of the . ... Mill. – Cement and Concrete Research, V ol. 33, 2003, 439-445. 16. D i n g, B. C. Modern ...

More- beneficiamento de entulho

- l équipement de sécurité en afrique du sud

- Processus Broyeur Dans Une Mine

- broyeur a boulets dans les mines de platine

- calcul des milieux de broyage dans un broyeur à boulet

- moulin à boulets de exploitation minière pour vente

- calcium carbonate grinding plant calcium

- vermiculite équipement de concassage de sable

- location d équipement de criblage de roches en asie

- point de pivot du concasseur à mâchoires

- concasseur mobile de minerai de fer d occasion en inde

- usines de broyeur sayaji

- Wildebees de martelo

- Ebay air classifier moulin poudre fine

- quartz mâchoire de pierre