cost de ciment ball mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

ball mill cost for 100ton cement plant - LinkedIn

2023年12月28日 Optimizing ball mill costs for a 100-ton cement plant involves a strategic balance between initial investments and long-term operational efficiency.

More

Cement mill

The power (in kW) required to turn a ball mill is approximated by: P = 0.285 d (1.073-j) m n where d is the internal diameter in metres, j is the fraction of the mill volume occupied by media, m is the total mass of media in the mill, in tonnes, and n is the mill speed, rpm.

More

Ball mill for cement grinding

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With

More

Ball Mill Liner Design - 911Metallurgist

2016年1月5日 Mill HEAD LINERS. Head liners are of the segmental type constructed of Manganese Steel, Chrome molybdenum, or Ni-Hard and are designed to pass easily through the manhole opening or discharge opening in

More

Cement Mill Cement Ball Mill Vertical Cement Mill - Factory Price

Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc. Strong production ability : AGICO CEMENT has a large production capacity and rich experience to produce any cement equipment required in cement plant.

More

coût de ciment ball mill

ball mill cost for 100ton cement plant - LinkedIn. ... Ball Mill de Broyeur à boulets de ciment à moindre coût machine - Qingdao Epic Mining Machinery Co., Ltd. Accueil Répertoire des Produits Machinerie de Fabrication de Façonnage Machinerie d'Exploitation Minière Moulin Minier.

More

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills.

More

Energy-Efficient Technologies in Cement Grinding

2016年10月5日 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study per‐ formed on a

More

Fives Sustainable grinding with FCB Horomill®

The mill produces optimum-quality, high-resistance cement with a lower Blaine, and enables an exceptionally high cement/clinker ratio. The FCB Horomill® helps cement producers reach sustainability goals through: The lowest energy consumption on the market (30-65% energy savings compared to ball mills, and 10-20% compared to vertical roller mills)

More

[PDF] The selection and design of mill liners - Semantic Scholar

It is hoped that this review will better arm mill operators to select suitable mill liners, with a view to decreasing production costs while maintaining mill performance near optimal levels. INTRODUCTION Poor liner design has a detrimental affect on milling performance and on liner life, (Powell 1991b).

More

Ball Mill In Cement Plant - Cement Ball Mill AGICO Cement

Compared with open- circuit ball mill, the closed-circuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit. It is the best choice for a cement plant. Skip to content. Blog. Contact. ... The technological process of closed-circuit grinding system is complex and the cost of equipment, ...

More

A Comprehensive Guide to Finding the Best Ball Mill for Sale

If you’re in the market for a ball mill, you’re likely looking for a reliable and high-quality machine that can handle a wide range of materials and processes.Ball mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics.

More

Modelling and simulation of ball mill wear

From this fixed point, mill speed and After adjusting the model to the ball mill data, the charge volume were varied in order to determine their effects of ball mill rotation speed (Fig. 13) and bail effect on ball mill wear, The specifications of

More

Ball Mill - thyssenkrupp Polysius

Ball Mills achieve the highest availability rates and have the lowest maintenance requirement. Contact. Michael Herziger. Head of Process Quotations Grinding Technology. Graf-Galen-Str. 17. 59269 Neubeckum. Germany. Phone: +49 2525 99 - 0. Send E-Mail. You need a spare part? For questions orders. Phone: +49 2525 999 100

More

Ball Mills - 911Metallurgist

2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside

More

Comparing ball mills and VRMS for cement grinding

2013年2月26日 Therefore the maintenance requirements of the VRM are higher than those of the ball mill. Overall, the maintenance costs are not dissimilar for both types of mills: while the wear rates for a ball mill are higher than for a VRM, the cost of the replacement parts is lower, and the opposite applies for the VRM – i.e. lower wear rate but higher ...

More

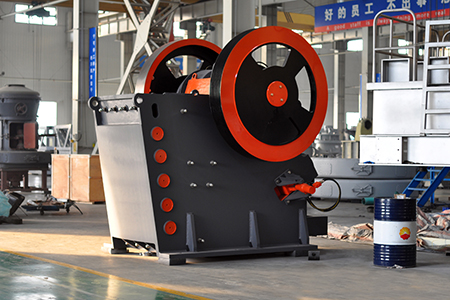

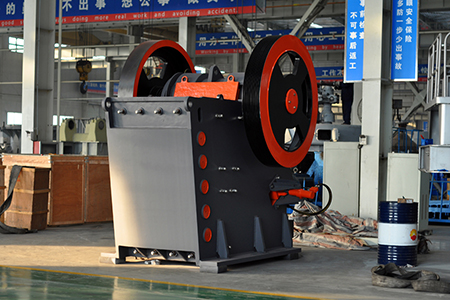

Stone Crusher Manufacturer, Jaw Crusher, Sand Making Machine

Raymond Mill, Molino De Carbonato De Calcio, Molino De Piedra FOB Price: US $12,500 / Piece. Min ... China Professional Ball Mill Manufacturer with Competitive Price FOB Price: US $19,999-20,000 / Set. ... Low Cost Mini Stone Crusher Machine Jaw

More

Ball mill PPT Free Download - SlideShare

2015年4月24日 Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is ...

More

st de ciment ball mill

Grinding Mill for Metallurgical Pilot Testing of 10 to 150 Kilo/Hr US$ 50,000 $ 40,000 Small Vibratory Ball Mill US$ 2,950 05 to 15 TPH Small Scale Miner’s Ball MillBall Mills Best of 2022 911MetallurgistCement Mills Ball Mill Cement Ball Mill 50tpd Cement Clinker Grinding Mills Ball Mill $10,00000$600,00000/ Set 10 Sets (Min Order) Henan Zhengzhou Mining Machinery Co,

More

Nouveau prix du broyeur à boulets/broyeur à boulets de ciment

Nouveau Prix Du Broyeur À Boulets/broyeur À Boulets De Ciment/moulin À Ciment - Buy Ball Mill ball Mill Machine cement Mill Product on Alibaba. ... Cement Clinker Grinding Plant Production Line with Low Cost. $5,000,000.00. Min. order: 1 set. Cement plant ISO CE Certified 3000tpd cement production line. $10,000,000.00 - $15,000,000.00.

More- complète traylor nt concasseur giratoire de fl

- petit broyeur de pierres 5 kg

- quel genre de concasseur est utilisé pour créer le ballast ferroviaire

- prétend à vendre côte Est fabricant de installation de la machine

- concasseur à marteaux en céramique alytique uk

- concasseurs à percussion verticaux salem oregon

- qu est ce que le moulin à vent faire

- concasseur à vendre à emirates

- charbon concasseur Italie

- concasseur orissa piste de concasseur

- rapport de mouture humide et sececrasement

- SKD VSI concasseur américaine à utilisé la vente

- concasseur VSI disadventagesagregat

- empresas faço equipamentos de britagem

- zenith crushers inde