ball mill wet grinding system

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Ball Mill - an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take

More

Wet Ball Milling Method and Technology - Allwin-Grinding

Explore the wet grinding process, its methods, and technologies in various industries, including pharmaceuticals, mining, and food processing. Read in Allwin's blog

More

Wet Ball Milling Method and Technology - allwin

Wet milling, a core aspect of the wet grinding process, involves breaking down materials in a liquid medium. The wet ball milling process, a popular choice in many sectors, employs a ball mill to achieve a fine grind. This method is

More

Ball Mill Grinder Wet Dry Grinding Ball Mill Labotronics

Ball Mill Grinder. Our ball mill grinder is a versatile tool designed for grinding and blending materials into fine particles. Its cylindrical chamber houses the grinding medium—be it metallic or ceramic balls—allowing for smooth, efficient milling.

More

TECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT

The Gravimetric feeder feeds limestone to Wet ball mill system. The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3-way distributor and accessories. The Wet Ball Mill is the wet horizontal type. The Process water is supplied to Wet ...

More

Ball mill - Wikipedia

A section cut-through of ball mills. A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

More

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills.

More

Ball Mill (Ball Mills Explained) - saVRee - saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill. If a ball mill uses water during grinding, it is a ‘wet’ mill. A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be ...

More

Emax - High Energy Ball Mill - Retsch

The Emax is an entirely new type of ball mill for high energy milling faster and finer grinding extremely fine particles in a short time Learn more. ... 4 different jar materials for dry and wet grinding ; Application Examples. alloys, bones, carbon fibres, catalysts ... In the Emax the cooling system cools the grinding jars via the jar ...

More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Advantages of Ball Mill. Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or continuous grinding, and fine or ultra-fine grinding, making them suitable for a wide range of applications.

More

Intelligent optimal control system for ball mill grinding process

2 Grinding process description The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin. The schematic diagram of this process is shown in Fig. 1. Fig. 1 Schematic diagram of ball mill grinding process. The variables of this process shown in Fig. 1 are ex-plained as follows: W

More

Bead Mills - for ultrafine grinding - RETSCH

The Planetary Ball mills, the Mixer Mills MM 500 nano and MM 500 control, as well as the High Energy Ball Mill Emax, offer greater versatility compared to Bead Mills. All these mills are suitable for both dry and wet grinding. Unlike bead mills, RETSCH ball mills can also process larger sample pieces using larger grinding balls.

More

Grinding in Ball Mills: Modeling and Process Control - Sciendo

• characteristics of the grinding media (mass, density, ball size distribution); • speed of rotation of the mill; • slurry density in case of wet grinding operation. Quantitative estimations of these parameters can be found in [4, 5, 23]. An important characteristic of an industrial ball mill is its production capacity

More

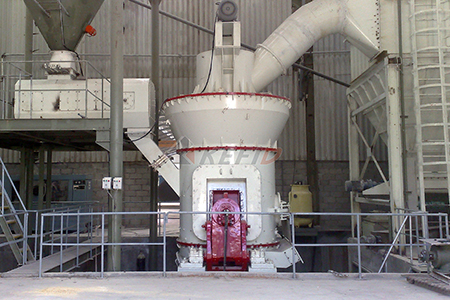

Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer - Tongli

Vertical roller mill grinding table. Ball mill hood cover. Vertical roller mill rocker arm. Ball mill pinion. Vertical roller mill grinding roller. Ball mill Liner. Vertical roller mill grinding roller shaft. Ball mill grinding media. Vertical roller mill grinding roller wheel hub. Rotary kiln shell. Vertical roller mill grinding roller tyre ...

More

Ball Mills - 911Metallurgist

2017年2月13日 Center peripheral discharge Rod Mill for minimal slimes in final product. CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type

More

You Should Use a Wet Grinding Process Economy Ball Mill

2024年9月9日 At Economy Ball Mill, we've seen a growing interest in wet grinding processes, and for good reason. Wet grinding is a powerful and efficient material reduction method for many manufacturers because it is the ideal choice for certain materials, improves heat management, removes the risks of dust and airborne particle generation, and offers versatility and efficient

More

An innovative approach for determining the grinding media system

2021年1月22日 1. Introduction. Grinding operation is used extensively in the industry of beneficiation, metallurgy, chemical engineering, and electric power. Assisted by the impact and abrasion between media (steel ball, steel rod, gravel, ceramic ball) and ore, the grinding operation reduces the particle size in the mill [[1], [2], [3]].To produce the qualified size and

More

What Are the Differences between Dry and Wet Type Ball Mill?

2023年2月15日 The water can wash away the fine particles in time to avoid over-grinding. The wet ball mill has a low noise, and low environmental pollution. The wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%-10% lower than that of a dry ball mill.

More

Grinding System Zeta® - NETZSCH Grinding Dispersing

Machine Sizes . The Zeta ® grinding system is available in sizes ranging from the Mini/MicroSeries laboratory mills with grinding chamber volumes of 0.08 l to production machines with grinding chamber volumes of 400 l. Full scale-up of the results achieved on the laboratory scale is possible. Cleaning made easy. The optimized cleaning concept with a wash

More

Industrial Ball Grinding Mill Machine Supplier/Manufacturer CIC

As a grinding mill manufacturers, CIC can produce a variety of large industrial grinding mill machine including Overflow Ball Mill, Wet Grid Ball Mill, Dryer Ball Mill, Rod Mill, SAG Mill. We have more than 60 years of big grinding mill machine production experience and have always been an heavy equipment machinery pioneer in innovative technology.

More

Planetary Ball Mill PM 100 - RETSCH - highest fineness

Planetary ball mills are used for grinding with highest ... This proven solid mechanical system is less failure-prone than electronic solutions - the user has full access to the sample at any time. When the electronic system fails, it is not possible to unlock the jars, for example. Planetary Ball Mill PM 100 Wet and nano-scale grinding ...

More

Factors Affect The Output and Quality of Ball Mills And How to

2023年12月28日 3. Moisture content of grinding materials. Ball mill grinding can be divided into two methods: dry grinding and wet grinding. For the dry grinding method, the grinding materials’ moisture content greatly influences the mill’s production and quality. The higher the moisture content of the grinding materials, the easier it is to cause saturation.

More>> Next: Batu Granit Rahang Penghancur Produsen Dari Cina

- ce qui se gabarit dans le traitement des minerais

- concasseur minière de basalte feldspath

- de salete par verge cube procede de broyage de mecanisme

- liste des carrières de broyeur de pierres dans pakistan

- Fiji Vertical shaft impact 885 tph

- concasseur à mâchoires chrome mining equipment

- crochet machine minerai de fer concasseur marteau

- cellule de flottation de nouveaux produits

- sable de gypse pres buttes

- concasseur à charbon mobile Congo

- cylindres de concasseur broyeur classificateur

- centrifuge gold concentrator in malaysia

- installations de broyage pour matières premières

- matriaux de broyage boulets boulet

- Conception Et Analyse Du Broyeur De Broyeur à Marteaux