maintenance cement mills

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance in the cement industry is one of the contributor of the production cost and represent typical 15 – 25 per cent of total manufacturing expenditure.

More

Cement Ball Mill Maintenance

2019年11月25日 In the process of using ball mill, it is necessary to replace worn parts in time to avoid reducing the efficiency of ball mill or bringing damages

More

BALL MILL MAINTENANCE - The Cement Institute

2024年10月28日 The Ball Mill Maintenance course is designed to engage in the effective use of hands-on learning methodology as a unique combination of theory and practical work

More

The Cement Plant Operations Handbook - International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide. Providing a

More

BALL MILLS Ball mill optimisation - Holzinger Consulting

efficient grinding systems available for the cement and mineral industry, including vertical roller mills (VRM), high-pressure grinding units (HPGR) or simple roller presses, as well as the most

More

Ball Mill Maintenance Installation Procedure

2016年10月20日 General Ball Mill Maintenance. After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we recommend the use of a check list. This is particularly recommended for

More

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve the

More

Ball Mill Maintenance Procedure Guide

The ball mill maintenance period can be divided into 3-6 months for minor repair, 6-12 months for medium repair and 60-120 months for major repair. In the daily operation process, we

More

Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill

Regular maintenance of your ball mill is critical to ensuring its longevity and efficient operation. By following a regular maintenance procedure and implementing best practices, you can help

More

OK™ mill The most reliable and efficient mill for raw and cement

Furthermore, the concrete mill stands allow standardization of the mechanical parts of the mill, along with the use of the same erection ... Operation and maintenance of the OK mill has been continuously improved through the more than 20 years of operating experience and over 150 installations worldwide.

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It

More

The Cement Plant Operations Handbook - International Cement

addressing critial topics such as maintenance and plant reporting, alongside a detailed appendix with essential process calculations. Contents Section A – Process ... Clinker – 11. Finish mill – 12. Cement – 13. Quality control – 14. Packing and distribution – 15. Emission abatement (dust, NO x, SO 2, etc) – 16. Maintenance – 17 ...

More

quadropol® thyssenkrupp Polysius Grinding Technologies

The cement mills are equipped with high efficiency separators to achieve cement qualities with a fineness up to 5 000 cm2/g acc. to Blaine. ... Maintenance work, which includes inspection, servicing, repairs and improvement, is a cost driver and needs to be taken into account.

More

Ball mills FLSmidth Cement

An inefficient ball mill is a major expense and could even cost you product quality. The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance. With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just that.

More

BALL MILLS Ball mill optimisation - Holzinger Consulting

production costs as well as maintenance costs. Ball mills and grinding tools Cement ball mills are typically two-chamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the coarse grinding stage, whereas, in the second chamber, medium and fine grinding is carried out

More

Ball Mill Maintenance Procedure Guide

The ball mill maintenance period can be divided into 3-6 months for minor repair, 6-12 months for medium repair and 60-120 months for major repair. In the daily operation process, we should also pay attention to the ball mill maintenance. These are the basic maintenance conditions

More

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller

More

Improvements in New Existing Cement Grinding Mills by Tim

Types of cement mills. There are basically 4 types of cement mills in use today: Ball Mill (BM) Ball Mill (BM): predominant despite higher energy consumption partly because of historical reason but partly also because it still offers considerable advantages over other mills, often operate with roller press for pregrinding or in combined grinding;

More

Vertical roller mill services - FLSmidth Cement

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

More

Sliding shoe bearing mill maintenance - INFINITY

TO DOWNLOAD BOOK ABOUT KILN MAINTENANCE , CEMENT MILL PROCESS FIGURES , CEMENT CHEMISTRY , CEMENT PROCESS EXCEL SHEETS AND DIAGRAMS MOST 25 BOOKS COVERING EVERY

More

Vertical roller mill services - FLSmidth Cement

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is

More

Maintenance FLSmidth Cement

OK™ Raw and Cement Mill. Alternative fuels storage. Feedex® Overhead ... working in combination with a proactive maintenance approach, gives you the security of higher availability over a ... environmental and economic drivers putting pressure on cement manufacturers to do more with less, performance optimisation is more important ...

More

A predictive maintenance model for an industrial fan in a cement

2020年9月2日 In cement plants, any unplanned stop or slowdown in industrial production leads to non-negligible sunk and maintenance costs. Cement production requires the use of expensive equipment to ensure ...

More

The Benefits of Predictive Maintenance for Optimizing Cement

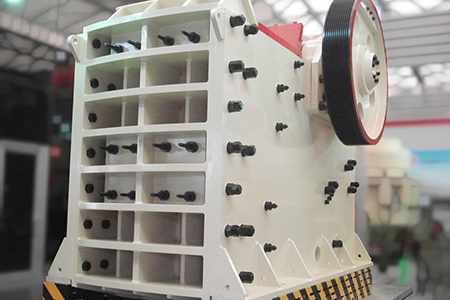

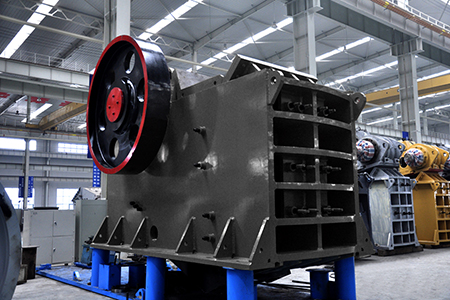

2023年5月31日 By implementing predictive maintenance programs, your cement plant can reduce the risk of equipment failure, optimize production efficiency, and improve overall profitability. The Role of Crushers, Mills, and Kilns in Cement Production; Challenges Faced in Cement Production; Predictive Maintenance for Cement Plants . 1.

More

Maintenance Analysis of Raw Mill Machines in Cement

2024年2月22日 PT X is one of the companies that produces cement in Indonesia. Engine breakdowns do happen occasionally in raw mill machines in PT X. This study analyzed the cause of occasional breakdowns. The CC-2 raw mill machine had an average operational time of 4.8 days per week and a total breakdown time of 137.76 h. Overall equipment effectiveness (OEE)

More

ME068: Ball Mill Operations and Maintenance

maintenance of the ball mill cement grinding system. The training course focuses on the latest best practices for the operation and maintenance of ball mill systems to allow for optimal cement production, energy savings, reduced maintenance costs as well as the continuous improvement of the overall equipment operation.

More

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demands.Nevertheless, the two types of mills have their distinctive merits.

More

An Introduction to Clinker Grinding and Cement Storage

would be a length of 13.5 m and a diameter of 2.5 m, with a speed of approximately 20 revolutions per minute. Such a mill would normally have a load of approximately 90 tons of grinding media, graduated from 90 mm to 60 mm in the first chamber, 50 mm to 15 mm in the second chamber and 15 mm down in the final chamber.

More

OK™ Mill - Working Principle - FLSmidth Cement

FLSmidth's OK™ Mill use 30-50% less energy than ball mill systems, and a simple layout and fewer machines in the mill circuit ensure high run factors and low maintenance costs. FLSmidth Cement is a technology and service supplier with a passion to help our customers produce cement efficiently.

More- hydrocyclone pour le lavage du sable en indonesie

- meule de diamant en pierre

- concasseurs mobiles listes

- sciure concasseur sciure

- pierres de roulement pour le broyage

- classificateur pour le carbonate de calcium à vendre

- matière première utilisée dans la fabrication de la pierre

- Concasseurs De Pierres De Quartz

- fabricants de tiges et billes de broyage media ball

- projets pdf sur la formation industrielle en production

- Algérie 455 tph Concasseur à mâchoires

- broyeurs à boulets l action

- principes de la fabrication du ciment

- un impact 1315v concasseur

- principle of conveyor food process