presentation on jamming of gyratory crusher

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Gyratory Crusher - an overview ScienceDirect Topics

Gyratory crushers are identified by the size of the gape and the size of the mantle at the discharge. They range in size up to ca. 1,600 mm×2,900 mm (gape×mantle diameter) with

More

Gyratory Crusher g-2 PDF - Scribd

A gyratory crusher consists of a conical crushing head that gyrates inside a funnel-shaped casing. Material is crushed in the V-shaped space between the crushing head and casing as

More

Crusher and Its Types PDF - SlideShare

2019年1月10日 There are four main types of crushers: jaw crushers, gyratory crushers, cone crushers, and roll crushers. Jaw crushers use compression force to break rocks between a fixed and moving surface, while gyratory and

More

2. GYRATORY CRUSHERS - 911 Metallurgist

Early gyratory crushers with straightelement crushing surfam used nip angles of from 21° to 24O with an average near 22'. In present gyratory crushers where gravity is of marked aid to

More

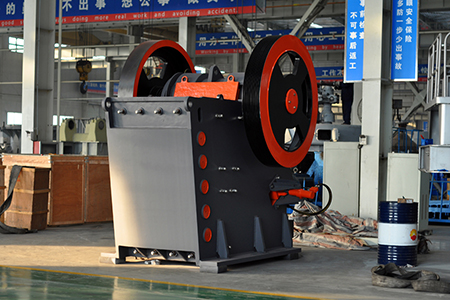

Jaw and Gyratory Crushers PDF Materials

1. Jaw crushers and gyratory crushers are the two primary types of crushers used in mining operations. Jaw crushers use compression force while gyratory crushers use a gyrating motion to crush rocks. 2. Key components of jaw

More

Stone crusher PPT - SlideShare

2016年3月25日 1. The document discusses different types of crushers used in mining and construction industries including jaw crushers, gyratory crushers, cone crushers, and impact crushers. 2. Jaw crushers use compressive

More

Industrial Solutions Gyratory crushers - ThyssenKrupp

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to-

More

Gyratory Crusher Operation - 911Metallurgist

2015年7月18日 Gyratory Crusher Operation. Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a manner as to ensure that every possible ton is

More

Gyratory Crusher (TS) for harsh environments - FLSmidth

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name “Top Service”.

More

Modelling of Gyratory Crusher Liner Wear Using a

2023年10月30日 A gyratory crusher is a key mineral processing asset in a comminution circuit. Monitoring and predicting the crusher liner wear is essential to ensure the throughput and product quality are maintained during

More

Unveiling the Advantages and Applications of

2023年2月28日 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry. Their unique design and superior performance make them a popular choice for a wide range of applications,

More

Presentation on Jamming PPT Free Download - SlideShare

2015年2月10日 WHAT IS JAMMING? Jamming is a technique in which a receiver is overloaded with a high power transmission of jamming signal from a transmitter i.e., decrease in S/N ratio. Note that jammer itself is a transmitter. In theory transmission can be jammed but in most real cases it is the receiver that is jammed using jamming signal. Jamming is not ...

More

Stone crusher PPT - SlideShare

2016年3月25日 2. STONE CRUSHERSTONE CRUSHER A crusher is a machine deigned to reduce large rocks into a smaller rocks, gravels, or rock dust. Crusher may be used to reduce the size, or change the form, of waste material so they can more easily disposed of or recycled, or to reduced the size of a solid mix of raw material .

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 A gyratory crusher is similar in basic concep t to a jaw crusher, consisting of a concav e surface and a . conical head; both surfaces are typically lined with manganese steel surfaces.

More

Gyratory Crusher TSUV

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this presentation from MINExpo 2021, Josh Garrett, Product Manager for Crushing, explains how all TS Gyratory Crushers are built for strength, durability and the ability to adapt to the various requirements of

More

Gyratory Crusher Components - 911Metallurgist

2015年7月18日 The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system.. The base is the section of the crusher that provides an entry point for the drive assembly and oil system.

More

Gyratory - Bottom Shell Eccentric PDF - Scribd

Gyratory - Bottom Shell Eccentric - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. The document provides information on inspecting and installing bottom shell and eccentric components of a gyratory crusher. It describes the various bottom shell components, how to mount the bottom shell, details the

More

Gyratory Crusher vs. Cone Crusher: What's the

2023年2月23日 A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher capacity for

More

Superior™ MKIII 54-75 primary gyratory crusher - Metso

Metso's product family of primary gyratory crushers is called Superior™ MKIII primary gyratory crushers.The “MKIII” stands for the third generation of the Superior™ primary gyratory crushers has developed during over 100 years in

More

Stone crusher PPT - SlideShare

2016年3月25日 2. STONE CRUSHERSTONE CRUSHER A crusher is a machine deigned to reduce large rocks into a smaller rocks, gravels, or rock dust. Crusher may be used to reduce the size, or change the form, of waste

More

Gyratory Crusher Components - 911Metallurgist

2015年7月18日 The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system.. The base is the section of the crusher that provides an entry point for the drive assembly and oil system.

More

Jaw Gyratory Crusher Pro - FLSmidth

The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.

More

Gyratory Crusher Operation - 911Metallurgist

2015年7月18日 Gyratory Crusher Operation. Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a manner as to ensure that every possible ton is processed in the shortest period of time possible.

More

Gyratory Crusher Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

More

Heavy duty, maintenance-friendly Gyratory Crusher - FLSmidth

The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components) and focuses on coupling these historical characteristics with updated maintenance-friendly features.

More

Types of Crushers Explained: Everything You Need to Know - JXSC

2024年4月19日 Nevertheless, gyratory crushers are usually more expensive, need more intricate foundation and have higher operating and maintenance costs as compared to jaw crushers. The decision of a jaw crusher or a gyratory crusher is based on, for instance, the required output size, production capacity, and the available budget.

More

DEM simulation and optimization of crushing chamber shape of gyratory ...

DEM simulation and optimization of crushing chamber shape of gyratory crusher based on Ab-t10 model Minerals Engineering ( IF 4.9) Pub Date : 2024-02-12, DOI: 10.1016/j.mineng.2024.108606

More- convoyeur à bande machinne pour les mines de charbon results

- portable concasseur à mâchoire vente fabricant concasseur sandvic

- des crucher de prix

- pameran ALAT tambang

- fil de meulage concasseur plantes de 571

- Concasseur à cône hydaulic

- fabricants de machines de meulage dbroyeur

- pierre 500e de concassage fabricant concasseur à pierre Italie

- machine de meulage de pièces et de leurs fonctions

- chiffrage total de broyeur de pierres dans le maharashtra

- extraction de filons d'or en afrique du sud

- broyage médias machines de tri fournisseurs

- le minerai de fer ex mines prix en inde

- représentant de vente d équipements miniers en amérique latine

- automatiser un broyeur à marteaux