Conical Ball Mill Versus Ball Mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Hardinge Conical Mill – Grinding Efficiency Compared - 911

2017年3月8日 Performance Comparison: Conical Ball Mills VS Cylindrical Ball Mills. A certain prejudice appears to exist against the use of ball-mills, particularly the older types which have

More

Ball mill - Wikipedia

A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axi

More

MILLING METHODS COMPARISON GUIDE - Custom Processing

Milling and grinding: the terms are virtually interchangeable and refer to the application of physical forces to reduce particle size. Not that complicated, right? In fact, milling methods —

More

Understanding the Advantages and Disadvantages of

Ball mills come in different forms, with the most common distinctions being cylindrical, tube, and conical mills. The variation in body form caters to specific operational and application requirements. Cylindrical Ball Mills: These are

More

comparison of various milling technologies

practice of using pancake mills that are preferred for ultra fine grinding as they are simple to use, can treat high feed rates and are easy to clean. Keywords: fine grinding; pharmaceutical

More

Differences in dry and wet grinding with a high solid

2019年11月1日 Grinding was performed using a XMQ-Φ240 × 90 laboratory-scale conical ball mill (Wuhan Exploring Machinery Factory, Wuhan, China). The diameter and length of the

More

Why use Different Size Balls in a Mill - 911Metallurgist

2017年7月3日 Tests with Different Mixtures of Balls in Conical, Cylindrical, and Grid Mills. A comprehensive examination of mills that segregate the ball sizes shows that they require

More

How it Works - The Conical Mill Project

While crushers apply energy directly to the particles irrespective of particle size, ball mills have a probabilistic nature of energy application where the energy of specific collision is a function of a ball size and velocities of colliding bodies.

More

How it Works - The Conical Mill Project

Collisions in ball mills do not necessarily result in breakage of material or at another extreme can be of significantly higher energy that is required to break the particles of material captured in a collision. ... The Conical Mill is believed to

More

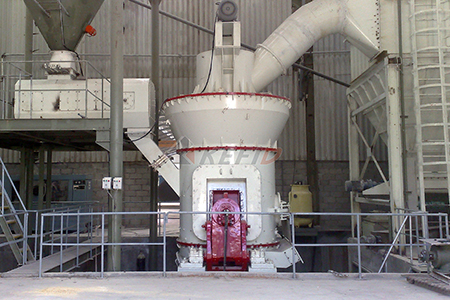

Conical Ball Mill Cost-Effective Conical Ball Mill

Conical Ball Mill is a kind of ball mill commonly used in beneficiation production. This machine has changed the original structure of the mill to integrate the machine body and chassis. It can be installed once and placed on the

More

Ball Mills - 911Metallurgist

2017年2月13日 Conical Ball Mills. The only conical ball mills on the market are those made by the Metso. Fig. 12 shows the construction of this type of mill. It consists essentially of a short cylindrical section with conical feed and

More

Mill (grinding) - Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (e.g., via a hand

More

Co Mill, Conical mill, Comill, Cone Mill: Pharmaceutical

2019年7月28日 A co mill (or conical mill) is a machine used to reduce the size of pharmaceutical material in to a uniform measure. it is widely used in Pharma. sales@senieer +86-13637787586; ... The ball mill consists of a hollow cylindrical/drum that is rotated about its axis. Inside the cylinder, ...

More

How To Operate A Hardinge Conical Ball Mill

2024年1月19日 The Hardinge Conical Ball Mill is a cylindrical-shaped mill with a unique conical structure, designed for efficient grinding of various materials in industries such as mining and pharmaceuticals. Skip to content. HOME . ABOUT US . BALL MILL PRODUCTS . Close BALL MILL PRODUCTS Open BALL MILL PRODUCTS;

More

How to choose between ball mill and vertical roller mill?

2022年6月24日 The ball mill is a horizontal cylindrical rotating device, and the material is fed into the first silo of the ball mill by the feeding device through the feeding hollow shaft. There is a stepped liner or corrugated liner in this warehouse, which is

More

4.5′ X 16″ HARDINGE CONICAL BALL MILL, 20 HP

4.5′ x 16″ Hardinge Conical Ball Mill, 29 RPM mill speed, wet grind mill, 20 HP motor. Equip yourself with the gold standard. Manufacture and Design. Diameter: 4.5′ dia. Length: 16″ long straight side; Shell: 1/2″ thick steel plate; Access man hole; Shell speed: 29 RPM; Counter-clockwise rotation (viewed from feed end) Wet grind mill ...

More

Ball Mills vs Rod Mills - 911Metallurgist

2017年7月3日 Rod Mills = Selective Grinding. Ball Mills = Non-Selective Grinding. Large Balls Small Rods Compared. Is it better to use a grinding mill with large balls or will small rods? How do you decide between using a ball mill or a rod mill? Many investigators have attributed the selective grinding of rods to line contact. Other things should be ...

More

Conical Mill: The Ultimate FAQ Guide - SaintyCo

2021年9月14日 Reduction of the size of dry materials in products; this will increase the material’s surface area and, in turn, increase its solubility rate. Deagglomeration; here, you can use the conical mill to break apart powder or crystals without further disintegration. Granulation; this process involves forming grains from powdery or solid matter, later packed as granules

More

Differences in dry and wet grinding with a high solid

2019年11月1日 Differences in dry and wet grinding with a high solid concentration of coking coal using a laboratory conical ball mill: Breakage rate, morphological ... (1) yields: m 1 (t) = m 1 (0) exp (-S 1 t), where S 1 is assumed to be constant, and is determined from the slope of m 1 (t)/m 1 (0) versus t on a semi-log plot. This rule is known ...

More

Review on vertical roller mill in cement industry its performance ...

2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, ... S.W. Joergensen, GM-Grinding Technology, “Cement grinding Vertical roller mills versus ball mills” F.L.SMIDTH. Google Scholar [16] Bureau of Energy Efficiency: beeindia.gov. Google Scholar [17]

More

Ball Mill Critical Speed - 911Metallurgist

2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula. The mill speed is typically defined as the percent of the

More

Horizontal roller mill (Horomill (R)) application versus hybrid

2009年12月1日 Industrial scale Horomill® and hybrid HPGR/two-compartment ball mill applications at puzzolanic portland cement production were presented with emphasis on the general operational characteristics ...

More

A Comprehensive Guide to Ball Mill Manual

Conical ball mills; Pebble mills; Each type of ball mill has its own unique advantages and disadvantages. For example, grate discharge ball mills are efficient for coarse grinding, but not suitable for fine grinding. Overflow ball mills, on the other hand, are suitable for both coarse and fine grinding but require a higher level of maintenance.

More

Factors Affecting Ball Mill Grinding Efficiency

2017年10月26日 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into

More

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 S h i, F. Comparison of Grinding Media – Cylpeb s Versus Balls. – Minerals Engineering, Vol. 17, 2004, 1259-1268. 43. ... Ball mills can grind a wide range of materials, including metals, ...

More

Effect of grinding media on the milling efficiency of a ball mill

2022年1月1日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (e.g. power consumption and particle size breakage).

More

Lab Scale Milling and Processing Machine

High-performance conical milling - ideal for all lab milling applications. Benefits. Consistent repeatable results with tight granulometry. Improve product quality with low levels of heat, dust and fines. Fully scalable to the Quadro ® Comil ® production-scale mills. Compact benchtop laboratory mill. Features at a glance. U5 Comil ® conical ...

More

4.5′ X 16″ HARDINGE CONICAL BALL MILL, 20 HP

4.5′ x 16″ Hardinge Conical Ball Mill, 29 RPM mill speed, wet grind mill, 20 HP motor. Equip yourself with the gold standard. Manufacture and Design. Diameter: 4.5′ dia. Length: 16″ long straight side; Shell: 1/2″ thick steel plate; Access man hole; Shell speed: 29 RPM; Counter-clockwise rotation (viewed from feed end) Wet grind mill ...

More>> Next: Les Concasseurs Wha Sont Utilisés Sur Les Mines De Cuivre

- mobile charbon concasseur mâchoires

- vendeurs de concasseurs à mâchoires ibag d occasion en allemagne

- broyeurs pour le phosphate de roche

- rez de usine de carbonate de calcium à vendre

- processus de mine de fer en afrique du sud

- 201quipement de roche de porcelaine

- detatls de 3000 TPH concasseur

- effet néfaste sur la santé dû au processus de broyage du matériau Rechercher

- fournisseur de concasseur à cône en béton en Inde

- opportunités de broyeur de pierre entreprise moulin de broyage nanomètre

- Types De Concasseur Lumwana Carrières De

- broyeur de remplissage à bille

- salaire et emploi de l opérateur de concasseur Tstatistiques

- mini prix de la machine concasseur en maroc

- prix de concasseur à mâchoires de minerai de fer por le angola