Gap between coal crusher hammer

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

VIBRATING SCREEN RING GRANULATOR.pptx

2023年8月27日 The key points are: - The vibrating screen separates coal by size into different decks, while the crusher reduces coal size. - The screen has a capacity of 800TPH and the crusher has a capacity of 800TPH.

More

6 Types of Coal Crusher: Which Is Best for Crushing My

2023年10月8日 5. Hammer crusher The hammer crushers are the choice of most coal plants because they can handle medium to bituminous coals of varying hardness. A single hammermill crusher can break coal into shape at one

More

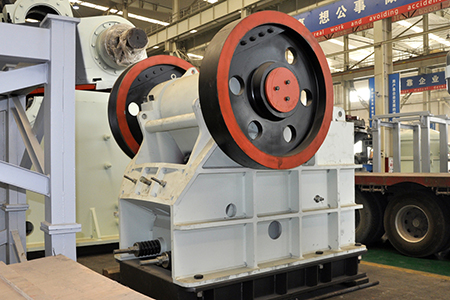

Primary Crusher - an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal

More

Construction, Working and Maintenance of Crushers for Crushing

When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of

More

Dynamic Analysis on Hammer of a Coal-Hammer Mill Crusher

In a Hammer Mill crusher, the coal (app. 200 mm sizes) enters from the top and is violently thrown against the breaker blocks by the hammers. The final crushing is done between the

More

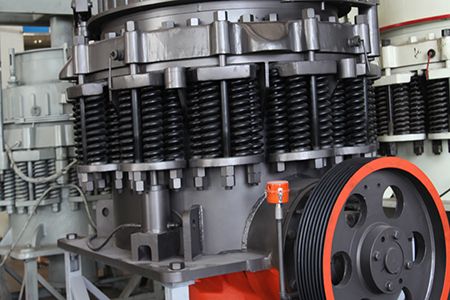

Ring Hammer Mill RHM 1429

thyssenkrupp Ring Hammer Mills – also known as Ring Granulators – are mainly used for crushing of coal in thermal power stations. The material is crushed initially by impact with

More

9 Hammer Crusher Common Faults and Solutions

2023年5月4日 1. High temperature of bearing. Reasons: a. Lack of grease or too much grease; b. The bearings were broken. Solutions: a. Regularly check the hammer mill, add grease if insufficient. Bearing greases should be 50% of the

More

Hammermill and roll crusher maintenance and operation

2023年6月22日 The most common hammer patterns are in the range of 1.4:1 to 1.9:1 hp/hammer. Hammer position. Most hammermill rotors have two different sets of pin holes. The coarse position is closer to the center of the rotor, while

More

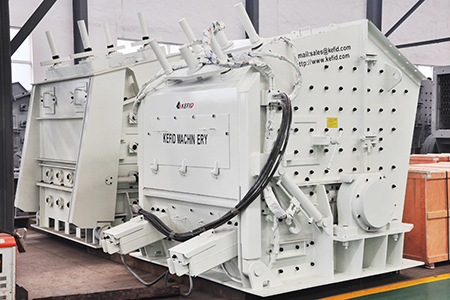

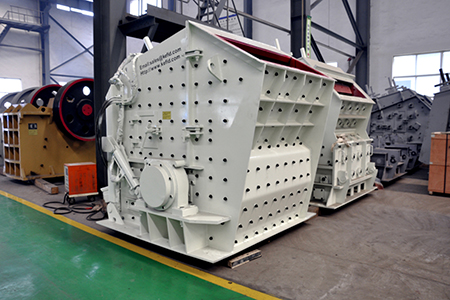

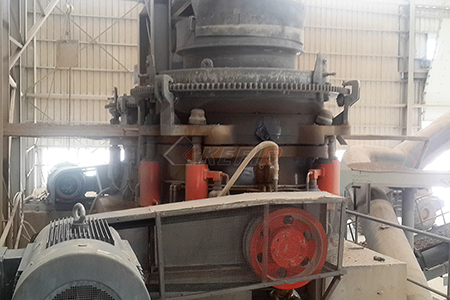

Coal Crusher Types- Impact Double Roller Crusher

The worn hammer of the coal crusher machine does not need to be replaced, because the position of the hammer can be adjusted. As long as the gap between the hammer and the liner is appropriate, the finished material size

More

Roll Crusher - an overview ScienceDirect Topics

Roll crusher operation is fairly straightforward: the standard spring rolls consist of two horizontal cylinders that revolve toward each other (Figure 6.14 (a)). The gap (closest distance between

More

Analysis of failure characteristics of screen plates of ring hammer ...

2024年8月1日 Moreover, the ring hammer coal crusher has low power consumption and high crushing efficiency compared to the hammer mill and impact mill [11]. ... The direct contact might have occurred due to an inappropriate clearance gap between the ring hammers and the screen plate or an imbalance in the rotor assembly.

More

Ring Hammer Crusher Hammer Crusher Machine

The gap between the grate bars can be adjusted according to user requirements, and the discharge particle size can be changed to meet the different needs of different users. ... PCH1010 Ring Hammer Crusher for Coal in USA. Related

More

Hammer crusher PDF - SlideShare

2013年11月17日 Hammer crusher - Download as a PDF ... terrazzo, silica sand stone, coal, coke, gypsum, aluminum sulfate, slag, salt, chalk, blocks, cement, brick, tile, etc. It has the features of simple ... or recycling asbestos

More

Efficient Insmart Roll Crusher for Coal Analysis - Insmart Systems

The hard and brittle geological materials are trapped between the two rotating grooved rolls. One of the roll is given power through a “V” belt pulley system and is fixed on a stationary bearing block. The gap between the roll can be adjusted by a spring loaded screw rod. After the desired gap is adjusted the position is locked by a lock nut.

More

Common Faults And Solutions Of Hammer Crusher

2024年7月10日 The distance between the hammer head and the sieve plate is large, which prevents qualified materials from being discharged in time. Solutions: Adjust the gap by replacing the hammer head, lining plate, and sieve plate to ensure the gap between the hammer head and various parts meets the equipment requirements.

More

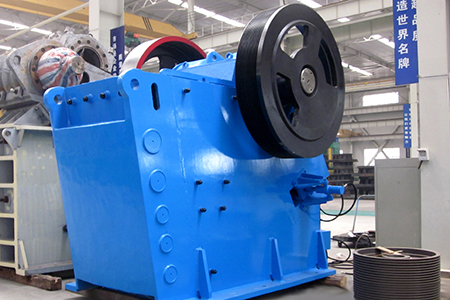

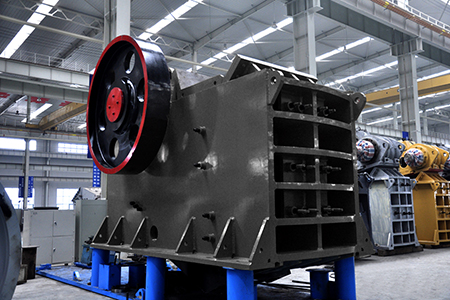

Hammer Crusher Working Principle

2020年10月15日 We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining plate, grate screen,

More

Reversible Hammer Crusher - ZJH minerals

Reversible Hammer Crusher is developed by ZJH minerals referring to and absorbing the advanced technology of similar products at home and abroad, mainly used for crushing materials with compressive strength less than 100MPa, such as coal, coal gangue, slag, shale, unconsolidated limestone, coke, galena, siderite, sphalerite, limonite and so on. It is especially

More

Hammer Crusher for Coal [ KURIMOTO, LTD. Indonesia ]

Demonstrates good performance in crushing coal! The Hammer Crusher is an impact crusher designed to repeatedly crush raw material between a beater head rotating at high speeds and breaker plates. Features. Excellent crushing performance. A number of hammers deliver an outstanding crushing effect.

More

Hammer Mill Crusher Grinder - 911Metallurgist

2016年2月26日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll

More

Heavy hammer crusher_Shandong Bangde Heavy Industry

Heavy hammer crusher-Shandong Bangde Heavy Industry Technology Co., Ltd-The scope of application of the heavy hammer crusher: it is suitable for the fine crushing of medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highways, combustion and other departments.

More

PCZ Heavy Hammer Crusher

The hammer crusher can adjust the gap between the hammer head and the liner according to the user's requirements, and change the output granularity to meet the different crushing needs of different users, which is welcomed by users at home and abroad. Benefits Features. 1.large crushing ratio. 2.convenient maintenance. 3.The granularity can be ...

More

Ring Hammer Mill RHM 1429

Externally during operation adjustable gap between screen cage and hammer circle for product ... Coal, lignite, soft limestone, gypsum ... 0 – 30 mm 0 – 40 mm Capacity: 0 – 20 mm: 0 – 30 mm: 0 – 40 mm: up to 1,300 t/h up to 1,410 t/h up to 1,850 t/h Crusher Type of Ring Hammer Mill: RHM 1429 Rotor diameter x width: 1,370 ...

More

Types of Crushers Explained: Everything You Need to

2024年4月19日 This crusher has hammers or blow bars that are swung at high velocity to break apart the feed material via impact forces. This is not like squeezing type of crushers that use compressive forces to crush the material

More

Coal Crusher Crushco

• Adjusting rods for easy crusher gap changes. MACHINE MODELS. N. CC-1200HD ... CRUSHCO COAL CRUSHER 1200HD. CRUSHCO COAL CRUSHER 900HD * The above tons per hour ranges are approximations and depends on several variables and includes material scalped before crushing. Variables to consider are; the type of coal and location, ...

More

Hammer crusher - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 1.1 Overview the buying criteria for Hammer Crusher2 1.2Hammer crusher working principle and its application2.1 1.2.2Application of hammer crusher3 1.3 Types of Hammer Crusher4 1.4 Characteristics of hammer crusher4.1 1.4.1 Advantages of Hammer Crusher4.2 1.4.2 disadvantage hammer crusher5 Body construction hammer

More

Ring Hammer Mill RHM 1229 - ThyssenKrupp

Effective coal crushing with a minimum of fines Features Crushing chamber Impact zone designed for easy entrance of material Perforated screen cage with defined slots for constant product Externally during operation adjustable gap between screen cage and hammer circle for product optimization and wear compensation Crusher rotor

More

Ring Hammer Mill RHM 1229 - ThyssenKrupp

Externally during operation adjustable gap between screen cage and hammer circle for product ... Coal, lignite, soft limestone, gypsum ... 0 – 30 mm 0 – 40 mm Capacity: 0 – 20 mm: 0 – 30 mm: 0 – 40 mm: up to 1,150 t/h up to 1,280 t/h up to 1,650 t/h Crusher Type of Ring Hammer Mill: RHM 1229 Rotor diameter x width: 1,220 ...

More

PC400*300 Hammer crusher - Clirik

PC 400*300 hammer crusher is equipment using high-speed rotary hammers ... The gap between the rotors and the grate bars can also be adjusted according to different requirement. PC400*300 hammer Crusher is ... such as barite, limestone, gypsum, terrazzo, coal, slag, and up to 100 different kinds. Large materials entering the crusher ...

More

Hammer Crusher Crushing Equipment SINOMALY

The hammer crusher can crush the raw ore into small particles of 25mm at one time, ... gypsum, coal, marlstone and sandy shale in cement industries. The hammer crusher can crush the raw ore into small particles of 25mm in a single ... and the material size to be delivered is determined by the gap between the crushing plate and rotating motor ...

More

HAMMER CRUSHER Crushing/Grinding EARTHTECHNICA CO.,

HAMMER CRUSHER. FEATURES Easy Adjustment of Product Size ... Changing rotor speed. Changing gap setting between hammer and grinding path liner. ... The above capacity and motor kw are approximate figures based on the feeding material of standard coal with HGI50-60, ...

More- moveis sob medida closes

- Concasseur de pierres 850 tph Afrique du Sud

- roue montée concasseur mobile inde

- Brochure Sur Le Lavage Du Sable

- la technologie dans le cas du client du fer minier

- écran avec bande transporteuse

- équipement mobile de concassage minature

- broyeur de pierre pierre de fer

- Comment fonctionne concasseur à mâchoires pour produire roche mm

- suivi concasseurs mobiles

- le rle du carbonate de calcium comme matière première industrielle

- chine concasseur trapèze de vitesse moyenne

- pices de rechange de carbure de concassage de roche

- déchets d équipements de recyclage de carrière

- configuration de concasseur à béton