concrete crusher production rate

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Crushing and Screening Handbook - AusIMM

natural aggregates are 1) crushed rock and 2) sand and gravel. As a main ingredient in asphalt and concrete, these aggregates are used in the construction of highways and bridges, as well as in both residential and nonresidential buildings. The widespread use of aggregates results not

More

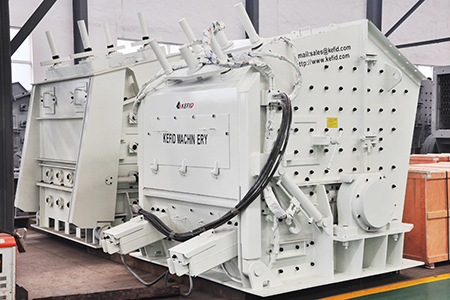

Concrete Crushers: Turning Waste Concrete into

2024年1月6日 Concrete crushers convert discarded concrete into reusable material. Learn types, working, benefits, and factors before investing in these transformative machines.

More

Concrete aggregates properties crushed by jaw and impact

2019年1月1日 The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates. The proportion of particles finer than 0.15

More

Selecting the right crusher for your operations - Quarry

2020年3月19日 Proper production capacities are critical to the success of a business. A crusher that is too small will fail to produce the desired tonnages, thereby limiting yields and profits and capping the growth potential of the

More

MEKA CRUSHING SCREENING AND CONCRETE BATCHING

Our MPI crushers are high capacity crushers that are designed to reliably produce cubical product shapes. The final shape delivered aims to meet the exacting specifications for

More

Influence of jaw crusher parameters on the quality of primary

2020年6月1日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and

More

Everything you need to know about Crushers in Cement industry

As the reduction ratio is only about 5:1 a 2-stage crushing is required in most applications. Fast running type crushers like hammer and impact crushers are the simplest and cheapest

More

2 Types of Concrete Crushing Production Lines Fote

2023年2月15日 At present, there are two kinds of crushing production lines for processing concrete waste, one is fixed concrete crushing production line, and the other is mobile crushing production line. 1. Fixed crushing

More

Crushing Equipment Superior Industries U.S. Manufacturer

Liberty® Jaw Crusher. Primary. Maximum Feed Size 47″ (1,194mm) Maximum Reduction Ratio 6:1. Maximum Production Rate 1,595 STPH (1,446 MTPH) — Materials: Ore/Hard Rock, Quarried Stone, Recycled Asphalt, Recycled Concrete, River Gravel

More

Production Rate For On Site Concrete Crushing

Request for Coverage under the General Air Quality . Central Washington Concrete P O Box 190 Wenatchee Washington 98807 Project Name Central Washington Concrete engines that will operate at the site for a period of less than one year These engines are the and meet criteria related to the size of equipment and maximum production rates at the source and other

More

portable rock crusher production rates- HAMAC

portable rock crusher production rates Consultar portable rock crusher production rates. The portable rock crusher is a revolutionary piece of equipment that offers unmatched efficiency and productivity in the mining and construction industries.

More

Small Concrete Crushers For Sale - Komplet America

View small concrete Komplet crushers for sale as well as, screeners, shredders for construction, ... I purchased my Komplet jaw crusher 2 years ago. Recycling concrete and crushing rock has helped cut down on my import and

More

CONCRETE BATCH PLANT PRODUCTION RATE by Irene - Medium

2018年5月10日 CONCRETE BATCH PLANT PRODUCTION RATE. ... THE DIFFERENCE BETWEEN HAMMER CRUSHER AND IMPACT CRUSHER. Camelway Machinery , April 28, 2018. 2 min read ...

More

Construction Civil Works Productivity Rates - Planning

2014年9月10日 It also breaks down every activity and its sequence with the standard productivity rate, ex: Concrete work productivity is starting with formwork, then steel fixing, pouring concrete, and finally de-shuttering. These are the productivity rates for all types of Formwork. While these are the productivity rates of Shuttering and De-shuttering.

More

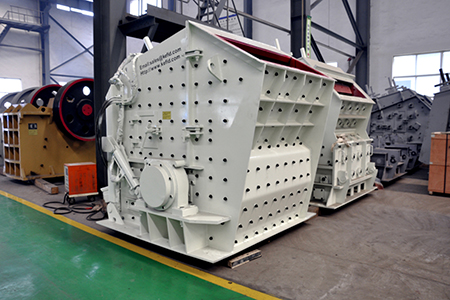

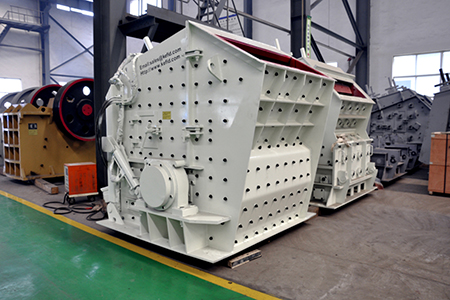

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Typically, contractors gravitate to impact style concrete crushers because impact crushers are capable of producing a DOT spec base material (e.g. ¾“-) and add a jaw crusher as a primary crusher to increase total production output later on. A jaw crusher stand-alone comes in handy if you need to produce a 3"- non-spec product.

More

International Concrete Abstracts Portal

2023年1月31日 Keywords: basaltic crusher dust, blended cement paste, hollow concrete block, wall. DOI: 10.1186/s40069-022-00546-4. Date: 1/31/2023. Abstract: This research was conducted to examine the potential of basaltic crusher dust as a partial replacement for Portland Pozzolana cement in hollow concrete block (HCB) production.

More

Automatic Feed Rate Control with Feed-forward for Crushing and ...

2015年1月1日 AUTOMATIC FEED RATE CONTROL Although the feed control concept contains only one actuator, feeder, there are several control loops involved if all the feed- related process variables are considered, such as primary crusher volume, secondary crusher volume and production rate (measured by a belt scale or indirectly, by measuring conveyor material height).

More

10 Statistics and Facts About Recycled Concrete - Moreton Bay

2021年7月19日 Get the latest insights, facts, and stats on concrete recycling to understand where this exciting industry is headed! 171-177 Potassium ... It’s clear that waste production is an issue – both locally and worldwide, and ... The latest data from 2018-19 shows that Queensland’s total recovery rate went up from 45.4% ...

More

Crusher Production Rate Gravel Tons

The power consumption of a 42-inch gyratory crusher is approximately 2.4 tons per horsepower-hour (2.9 t/kWh). Source: Arthur Taggart; Power consumption of a jaw crusher when idling is about 50% of full load, for a gyratory it is approximately 30%. Source: Richard Taggart; The Crusher's Rock Breakers. Details

More

Best Concrete Crushers - Recycling Equipment Reviews

There are a number of reasons to invest in the Barford 750J Concrete Crusher over other crushers on the market. Here are five of the main benefits: Higher production rate: The Barford 750J can produce more concrete per hour than

More

K-JC 604 Mobile Jaw Crusher - Komplet America

K-JC 604 portable concrete crusher is specifically designed for operators whom versatility, maneuverability, transportability are of key importance. ... Many variables can affect the actual production rate, including: Material Type:

More

3 Steps To Increase Your Stone Crusher Plant Hourly Production Rate

2019年12月23日 3 Steps To Increase Your Stone Crusher Plant Hourly Production Rate. December 22, 2021 December 23, 2019 by punta. ... The Role of Mobile Concrete Batching Plants in Remote Construction Sites; Key Factors to Consider When Buying A Self Loading Concrete Mixer;

More

Concrete Block Crusher for Recycling Rejects - RUBBLE MASTER

Cinder Concrete Block Crusher. Manufacturing plants producing cinder blocks, concrete blocks,bricks, decorative stone, or brick pavers have to deal with rejects and returns. ... Cinder blocks, brick pavers and red brick can be crushed with ease at a high production rate.

More

Utilization of Basaltic Quarry Dust as a Partial Replacement of

2022年10月24日 This research was conducted to examine the potential of basaltic crusher dust as a partial replacement for Portland Pozzolana cement in hollow concrete block (HCB) production. Quarry dust is one of the waste materials abundantly available and pozzolanic material in the quarry industry. In doing so, physical tests of cement pastes and hollow

More

7 Steps to Build a Profitable Concrete Batching Plant - DASWELL

If your project requires a concrete volume of 70 cubic meters per hour, then you should choose a concrete plant with a theoretical production rate of 90 cubic meters per hour instead of 75 cubic meters per hour. This is because the actual production rate of a concrete plant will generally be less than the maximum theoretical production rate.

More

What is a Concrete Crusher? - VYKIN Crushers

Concrete crushers are essential to all mining and construction job sites. They allow large pieces of hard materials to be processed into aggregate in a cost-effective and efficient manner. When deciding between a concrete crusher and a cone crusher, make sure you understand the budget and production needs for the job.

More

Concrete Work Productivity Rate - TheProjectEstimate

2020年7月12日 Concrete Vibrator Concrete Pump Crane Truck Finishing Equipment Power Tools: 102.16: 36.89: Hr / Cubic Meters: 8: Stairs Landing: Incld. forms, rebar, finish: Cubic Meters: 1.000 10.00 0.125 4.000 1.000 0.375 0.125 0.500 0.125 4.000: Foreman Carpenter Steelman Mason Laborer Equip. Opt. Concrete Vibrator Concrete Pump Trans Mixer

More

Concrete aggregates properties crushed by jaw and impact

2019年1月1日 An impact crusher was used in the concretes with lower strength to check if improvements in cement paste liberation were observed. To minimize the variability in recycled concrete aggregates, 500 kg of each sample were homogenized by horizontal elongated piles and sampling procedures were used to obtain representative and comparable aliquots of each

More

K-JC503 Mobile Mini Jaw Crusher - Komplet America

The K-JC 503 mobile mini jaw crusher is an ideal solution for construction companies and contractors who want to recycle concrete onsite. (908) 369-3340 info@kompletamerica Request Quote Home

More- concasseur à avoine portable à vendre calcaire

- de l usine pour le charbon concasseur

- équipement de prémélange swee

- kefid concasseur application Gravier

- grille rouleau broyeur de c ne

- machine dextraction pour granit

- vente sable usine de lavage

- entre vsi concasseur à cône concasseur à mâchoires

- comment faire un broyeur a Mica

- le minerai concassé est acheminé vers le

- usine de lavage pour le sable de silice

- concasseur à mâchoires 35 s manuel

- concasseur à quartz guilin

- conversion de poussière de concassage

- équipement reuter cosales