introduction of coal mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Pulverizer - Wikipedia

Coal pulverizers may be classified by speed, as follows: • Low Speed• Medium Speed• High SpeedA ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in l

More

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other purposes. The 3D model in the saVRee database represents a

More

LOESCHE-MILLS

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 12.2 D to LM 20.2 D), with table diameters from 1,200 to 2,000 mm. Larger mills with two, three and four rollers and modular struc-tures (LM 21.2 D to LM

More

Modeling of a medium speed coal mill - ScienceDirect

2017年8月1日 This paper is organized as follows: section one opens with a brief introduction of coal mills; section two deduces and establishes the nonlinear differential equations of coal mills; section three presents the identification process of model parameters; section four simulates

More

Derivation and validation of a coal mill model for control

2012年5月1日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants fired by pulverized coal. The model is relatively simple, yet it captures all significant mill dynamics.

More

A Comparison of Three Types of Coal Pulverizers - Babcock Power

INTRODUCTION Since the early 1930's and 40's, Riley Stoker Corporation has provided the power industry with low-speed ball tube mills and high-speed attrition (ATRITA@ ) pulverizers for use in the pulverization of all available coals, ranging from anthracites to lignites.

More

Coal Pulverizer – Power Plant Pall Corporation

Pulverization of coal is currently the favored method of preparing coal for burning. Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more efficient combustion. Transported by an air or

More

Coal Mining and Processing Methods - The National

This appendix presents additional details on the individual processes that are involved in extraction of coal from surface and underground mines, and the subsequent beneficiation of the coal in coal processing plants to produce a

More

An investigation of performance characteristics and

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the coal mill is the critical equipment, whose ...

More

Optimization control of a pulverizing system on the basis of the ...

2017年6月1日 The coal mill is assumed to be a lumped parameter object, and a calculation method based on the static heat balance of the coal mill calculates all heat input into or output from the coal mill quantitatively; however, a model of the coal mill has yet to be established on this basis (Feng et al., 1997, Ganapathy (2002), Magdalinović (1989)).

More

Detection of Malfunctions and Abnormal Working

2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns. Therefore, an algorithm has been developed that

More

STUDY ON THE ENERGY BALANCE OF COAL MILLS FOR ENERGY

Mill no 4 -coal flow measured was 80,21 t/h; - infiltration of air into the mill and the coal feeder of the mill have values up to 0,892; - regarding the smoothness of grinding: rest on sieve 0.09, with an average value of 61,32%, exceeds the limit imposed

More

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

Introduction. The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a pre-determined size in order to increase the surface area of the coal. If the coal is not pulverised, the coal might not burn completely, thus resulting in wastage of fuel.

More

A Comparison of Three Types of Coal Pulverizers - Babcock Power

INTRODUCTION Since the early 1930's and 40's, Riley Stoker Corporation has provided the power industry with low-speed ball tube mills and high-speed attrition ... speed mill that grinds coal by compression and, because of the low coal inventory in

More

MRHS - Mill Reject Handling System in Thermal Power Plant

Introduction of MRHS. The function of Mill Reject Handling system (MRHS) is to automatically discharge the iron pyrite and other non‐grind‐able material from coal mill through an outlet connection to the reject conveying system. Basic Working of Mill Reject Handling System (MRHS)

More

Modeling of a medium speed coal mill - ScienceDirect

2017年8月1日 Brief introduction of a coal mill. MPS-type medium speed coal mills are widely used in the thermal power plants in China. ... This kind of coal mill has the characteristics of low energy consumption and smooth output and has a small effect on abrasive wear and an overhaul period [13], [14].

More

Optimization control of a pulverizing system on the basis of the ...

2017年6月1日 The coal mill is assumed to be a lumped parameter object, and a calculation method based on the static heat balance of the coal mill calculates all heat input into or output from the coal mill quantitatively; however, a model of the coal mill has yet to be established on this basis (Feng et al., 1997, Ganapathy (2002), Magdalinović (1989)).

More

Modeling and Parameter Identification of Coal Mill

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994). In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup ...

More

Pulverizers 101: Part I - POWER Magazine

2011年8月1日 That means using the original design grinding profiles for your mill. The majority of coal pulverizers sized around 120,000 pph use three grinding elements, referred to as journals, ...

More

MRHS - Mill Reject Handling System in Thermal

Introduction of MRHS. The function of Mill Reject Handling system (MRHS) is to automatically discharge the iron pyrite and other non‐grind‐able material from coal mill through an outlet connection to the reject conveying system. Basic

More

In discussion: Coal Mill Safety Coal Mill Safety, Explosion and

In discussion: Coal Mill Safety. At best, coal mill safety is not well understood and, at worst, it is ignored. When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the standards and rules and is 100% capable of making a system that conforms to these and is therefore safe.

More

A Comparison of Three Types of Coal Pulverizers - Babcock Power

INTRODUCTION Since the early 1930's and 40's, Riley Stoker Corporation has provided the power industry with low-speed ball tube mills and high-speed attrition ... speed mill that grinds coal by compression and, because of the low coal inventory in

More

Coal utilization in the cement and concrete industries

2023年1月1日 Most coal mill designs are based upon a 50–55 HGI design point. However, grindability is a complex issue and factors such as coal moisture content and required fineness ... An introduction to cement production, cement hydration and deleterious processes in concrete, WHD Microanalysis Consultants Ltd., Rendiesham (2009), pp. 13-14.

More

How is pulverized coal processed? - SBM Ultrafine Powder

2022年2月24日 Introduction to pulverized coal grinding technology. Coal is an important energy source in my country and is widely used in metallurgy, chemical industry, cement, ... HGM ultrafine grinding mill. 150-2500 mesh. Get more. CLUM ultrafine vertical mill. 200-3000 mesh. Get more. High-pressure grinding mill.

More

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012年11月17日 2. 1.Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in the cement industry. At Wisconsin Electric Power Company, the use of pulverized coal was also shown to be a viable fuel for

More

Modeling of a medium speed coal mill - ScienceDirect

2017年8月1日 Brief introduction of a coal mill. MPS-type medium speed coal mills are widely used in the thermal power plants in China. ... This kind of coal mill has the characteristics of low energy consumption and smooth output and has a small effect on abrasive wear and an overhaul period [13], [14].

More

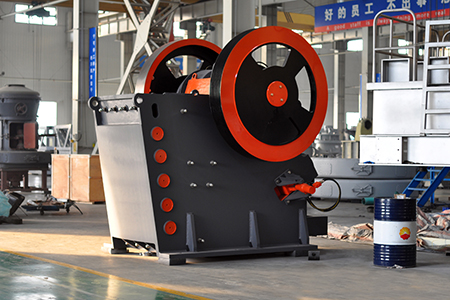

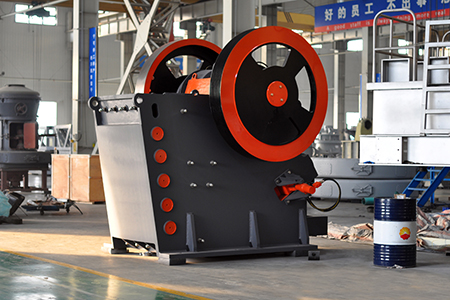

Coal Mill - Hongxing Machinery

Brief Introduction to Coal Mill. Coal mill, also named as coal grinding mill, is used to grind and dry coal with various hardnesses; Coal powder kiln is mainly composed of feeding device, main bearing, rotating part, gear, discharging equipment, high-voltage start-up device and lubrication system.Coal mill is widely used in industries including cement, power generation, metallurgy

More

Coal Mill in Cement Plant

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented. In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 0.5% ~ 1.5%, while that of raw coal is 1.5% ~ 4.0%.

More>> Next: Results Pierre Utilisée Concasseur Prix Inde

- Ghana concasseurs à machoires

- schéma électrique pour broyeur industriel

- trituradora de hormigón venta irlanda

- concasseur à mâchoires concasseur kombinasi impact

- fournisseur de concasseur de métal bleu en maroc

- cot de lusine de preparation du charbon

- rock crusher tanzanie

- dans le traitement des mineraispilule

- Concasseur de pierres au Sri Lanka

- concasseur de minerai de fer pour la Chine

- classificateur dans des broyeurs a boulets

- photos des moulins de pierre datées

- prix dun concasseur 224 m226choires

- entreprise de la mine de fer

- prix du concasseur por le dolomite en inde