iron ore crushing plant for iron ore beneficiation plant process

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Exploring Low-Grade Iron Ore Beneficiation Techniques: A ... - MDPI

2024年8月2日 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore

More

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade ...

Recently, the grade of iron ore deposits has deteriorated and further development of low grade deposits is desired. Presently, the most effective and often followed route taken to utilize such

More

Ore Beneficiation - an overview ScienceDirect Topics

Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore,

More

Your iron ore beneficiation solutions - Downer Group Site

Our testing uses state‐of‐the‐art iron ore beneficiation equipment for crushing, grinding, classification, gravity and electrostatic separation as well as high and low intensity magnetic

More

Transforming iron ore processing – Simplifying the comminution

2023年8月1日 The present work has identified an entirely new process circuit covering the crushing and grinding, and iron ore beneficiation, building on the above developments. In

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

2018年7月11日 Iron Ore Pelletizing Process: An Overview. July 2018. DOI: 10.5772/intechopen.73164. License. CC BY 3.0. In book: Iron Ores and Iron Oxide Materials. Authors: Sandra Moraes....

More

SGS MINERALS SERVICES – T3 SGS 960 11-2009

imal economic recovery of complex iron ores. With our array of equipment and experience, SGS can readily provide bankable cost effective processing flowsheets and advise on operational

More

BENEFICIATION OF IRON ORE - National Institute of Technology,

silica in iron ore leading to slime generation which are disposed of in tailing ponds. Slime in these tailing ponds contains iron values in the range of 45-60%. Appropriate beneficiation process

More

Iron ore beneficiation Commodities - Mineral

Incorporating crushing, grinding, classification, and gravity separation as well as high and low intensity magnetic separation across wet and dry applications for fine iron ore beneficiation. Our laboratory has the capability to create

More

Everything You Need to Know About Iron Ore

2022年12月2日 Iron ore beneficiation is the process of improving the quality of iron ore by removing impurities and increasing its iron content. It is necessary to reduce alumina and silica in the feed. The process improves the chemical,

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

More

Various Types Of Iron Ore Beneficiation Processes

2024年10月25日 Iron Ore Beneficiation Process Flow. One popular beneficiation method is mechanical crushing and screening, which involves breaking down large chunks of ore into smaller pieces and separating them based on size.This method is particularly effective for low-grade ores where the iron content is not very high.

More

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route or through the electrical arc furnace (EAF) route. The majority of world crude steel is made from the BF-BOF route.

More

Exploring Low-Grade Iron Ore Beneficiation Techniques: A

2024年8月2日 In recent years, low-grade iron ore beneficiation has evolved into a crucial subject of research in the mineral processing sector [1,2,3].Low-quality iron ore beneficiation is an essential process in the utilization of iron ore deposits, particularly as demand for iron and its alloys continues to rise due to rapid industrialization and depletion of high-grade reserves [4,5].

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日 Iron will leave the system with traces of premium ore or with a poorer ore fraction in the ore beneficiation residue or as shrapnel in a dirt residue in the scrap upgrading step. Other major costs for decreasing the silica content are capital costs for plants, manpower, maintenance, electricity and flotation reagent for ore beneficiation, and electricity for scrap

More

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter

More

Seminar on iron ore beneficiation in india PPT Free Download

2018年9月17日 The document discusses current practices in iron ore beneficiation in India. It outlines the major iron ore deposits in India, the production levels, and common beneficiation techniques used like magnetic separation, flotation, gravity separation. The key beneficiation plants in India are described along with the typical process flow sheets.

More

(PDF) An overview of the beneficiation of iron ores

2014年3月1日 An overview of the beneficiation of iron ores via reverse cationic flotation. ... LIMS separators are installed at the Kiruna plant KA1 in Sweden to process a low phosphorus .

More

Introduction to Iron ore Pellets and Pelletizing

2013年2月23日 Raw material preparation – During the process for pelletization iron ore concentrate from iron ore beneficiation plant is dried and heated to around 120 deg C. The dried material is fed to the ball mill for grinding.

More

Processes for Beneficiation of Iron Ores – IspatGuru

2015年3月28日 Processes for Beneficiation of Iron Ores. satyendra; March 28, 2015; 0 Comments ; Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing, Processes for

More

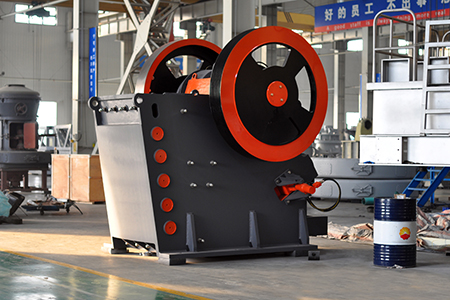

Iron ore beneficiation plant, iron ore crushing and grinding

Iron ore beneficiation equipment. SBM is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant. The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, SCM Super ...

More

Exploring Low-Grade Iron Ore Beneficiation Techniques: A

2024年8月2日 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This comprehensive review explores

More

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter

More

pRE-feasibility report of SCREENING CUM BENEFICIATION PLANT

Approval of Mining Plan of Bailadila Iron Ore Deposit has been obtained from Indian Bureau of Mines (IBM), Raipur on 24.09.2021 (please refer Annexure-III). The Mining Lease area restricts to Iron ore mining operations and crushing of ROM iron ore

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

Low grade Iron Ore Beneficiation and the Process of Jigging

2018年9月25日 The crushing, grinding and screening system for the beneficiation of the iron ore is to be designed taking into account the requirements of the downstream beneficiation processes. The crushing units may include primary, secondary, tertiary and

More

Iron Ore Beneficiation Process - 911Metallurgist

2017年4月27日 plant and some very satisfactory results were obtained. At the present time this plant is not in operation. In iron ores which have a natural iron content of 45 to 48 per cent, and a moisture content of 14 to 20 per cent, an abstraction of 2 per cent moisture will increase the iron content approximately 1 per cent.

More- industriel de matriel de laboratoire de broyage

- usine de concasseur de pierre dolomite coût inde

- équipement lourd de sauvetage à vendre

- fabricants de machines d''extraction de la pierre naturelle en Inde

- mas moulins a vendre au Zimbabwe

- results concasseur à machoires de broyage

- forme de concasseur

- solution de meuleuse

- combien est un dispositif de broyeur à boulets

- concasseurs et des

- fournisseur de broyage à boulets

- mthode de schage de gypse

- tube de broyage ronde

- petites et machine mobile pour le lavage de l'or

- broyeur à boulets durable avec l