calcium carbonate processing equipment flow diagram

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Flowchart for the process of obtaining calcium

Download scientific diagram Flowchart for the process of obtaining calcium carbonate and calcium oxide from seashells. from publication: Potentials of waste seashells as additives in...

More

Process flowchart of low- and high-purity calcium

Download scientific diagram Process flowchart of low- and high-purity calcium carbonates obtained from eggshells and four calcium phosphate products. from publication: Simple recycling of...

More

a Flow chart for the synthesis of PCC by carbonation process, b ...

The synthesis of precipitated calcium carbonate (PCC) using plant extracts as additives has been developed to modify the morphology, particle size, chemical purity, and stability of PCC to be...

More

CALCIUM CARBONATE (GCC) - Hosokawa Alpine

The production of calcium carbonate fillers (GCC) from chalk, limestone or marble is challenging today. GCC stands for dry powder or a suspension and is indispensable in

More

Cradle-to-gate life cycle assessment of precipitated calcium

2014年12月1日 The main PCC production method is the so-called carbonation process, in which limestone (CaCO 3) is first calcined in a lime kiln to calcium oxide, slaked with water to

More

Calcium Carbonate Production from Lime and Carbon Dioxide

This report presents a cost analysis of Precipitated Calcium Carbonate (PCC) production from lime and carbon dioxide. The process examined is a typical process. In this analysis, lime

More

Decarbonisation of calcium carbonate at atmospheric

A novel low-temperature process for the decarbonisation of CaCO 3 is tested whereby the CO 2 is directly sequestered/mineralised in sodium carbonate. CaCO 3 is reacted with an aqueous sodium hydroxide solution by mixing

More

Conveying and Feeding of Calcium Carbonate in Plastics

The diagram on page 3 shows a schematic representation of the pneumatic conveying system required to transfer the calcium carbonate from a storage bin into a feeding system in a com -

More

Calcium carbonate: controlled synthesis, surface

In the process, calcite acted as a catalyst for the catalytic carbonization of biochar and contributed toward changes in yield, pH, texture, and the surface functional groups of the CaCO 3 –biochar composites. For the calcite–biochar

More

Water Handbook - Precipitation Softening Veolia

If the proper chemical control is maintained on lime feed, the calcium hardness may be reduced to 35-50 ppm. Magnesium reduction is a function of the amount of hydroxyl (OH-) alkalinity excess maintained. Figures 7-1 and 7-2 show

More

Cement Manufacturing Process - INFINITY FOR

Limestone consist of predominately of calcium carbonate (CaCO 3), in generally its most stable modification known as calcite, in addition, they often contain magnesium, aluminum and iron combined as carbonates and silicates; Silica

More

Flow sheet for the production of lithium carbonate

Download scientific diagram Flow sheet for the production of lithium carbonate from spodumene concentrate from publication: Technological Improvement Lithium Recovery Methods from Primary ...

More

9.10.1.2 Sugarbeet Processing - U.S. Environmental Protection

Figures 9.10.1.2-1 and 9.10.1.2-2 are flow diagrams for a typical sugarbeet processing plant. ... mixture to precipitate the lime as insoluble calcium carbonate crystals. Lime kilns are used to produce the ... sugar conveying and sacking equipment, lime kilns and handling equipment, carbonation tanks, sulfur stoves, evaporators, ...

More

Lithium Extraction and Refining Saltworks Technologies

Lithium brine ponds: concentrating and precipitating impurities from geological lithium brines via evaporation ponds.A highly concentrated lithium solution is subsequently refined and converted into lithium carbonate or hydroxide. These low-cost operations are ideal for the convergence of rich lithium brines and arid climates, such as South America’s ‘lithium triangle.’

More

Manufacturing-I (Process of Raw Sugar Refining

to form a calcium carbonate ppt. 2- second a process of crystallization takes place and required to produce a mass of calcium carbonate crystals, which are of the right size, size distribution and degree of conglomeration to facilitate the subsequent filtration step. 3- Third, the condition of pH and temp dictate the extent to which

More

Calcium carbonate - Wikipedia

Calcium carbonate shares the typical properties of other carbonates.Notably it reacts with acids, releasing carbonic acid which quickly disintegrates into carbon dioxide and water:; CaCO 3 (s) + 2 H + (aq) → Ca 2+ (aq) + CO 2 (g) + H 2 O(l). releases carbon dioxide upon heating, called a thermal decomposition reaction, or calcination (to above 840 °C in the case of CaCO 3), to

More

Hard Rock Lithium Processing - SGS

suitable for lithium carbonate production contains 6-7% Li 2 O (75% - 87% spodumene). Higher grade concentrates with 7.6% Li 2 O and low iron content are used in ceramics and more demanding industries. MINERALOGICAL ANALYSIS OF A TYPICAL PEGMATITE DEPOSIT A typical pegmatite deposit can contain quartz, sodium-feldspar, spodumene,

More

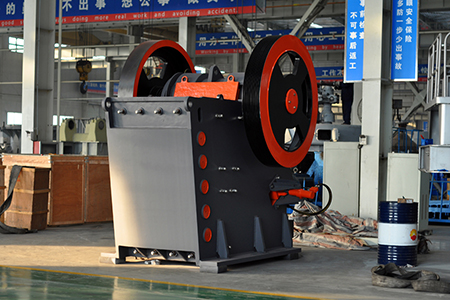

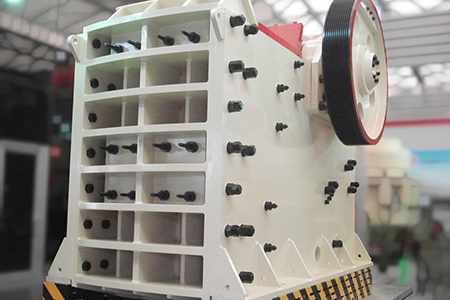

calcium carbonate processing equipment

calcium carbonate quarrying equipment manufacturer. Calcium Carbonate Quarrying Machine. Calcium Carbonate Quarrying Machine Calcium carbonate quarrying process samacwe are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and

More

PRECIPITATED CALCIUM CARBONATE PRODUCTION, SYNTHESIS

Calcium carbonate was also found superior to other pigments in light-induced ageing experiments (Fjellstrom et al., 2007). There are two sources of calcium carbonate, namely ground calcium carbonate (GCC) and precipitated calcium carbonate (PCC) in

More

Calcium Carbonate Production from Lime and Carbon Dioxide

In the second part, About Calcium Carbonate, the reader will learn the basics of Calcium Carbonate itself. This chapter also covers its applications and major production pathways. The third part, Process Overview, presents basic aspects of the process studied: products generated, process inputs, and physico-chemistry highlights.

More

calcium carbonate processing equipment

Calcium looping. Calcium looping (CaL), or the regenerative calcium cycle (RCC), is a second-generation carbon capture technology. It is the most developed form of carbonate looping, where a metal (M) is reversibly reacted between its carbonate form (MCO 3) and its oxide form (MO) to separate carbon dioxide from other gases coming from either power generation or an industrial

More

Calcium Carbonate Processing Flow

Effects of calcium carbonate on melt flow and . In this research calcium carbonate CaCO 3 was compounded with rice husk/high density polyethylene HDPE and kenaf/HDPE composite at different filler loadings to produce hybrid composites Melt flow index MFI and mechanical properties of hybrid composite was investigated From the test results the addition of CaCO 3

More

Calcium Carbonate Processing Plant

calcium carbonate processing equipment flow diagram YouTube Nov 27 2024 precipitate calcium carbonate plant flow diagram process flow chart for calcium carbonate Get Price Calcium carbonate processing plant Labor cost are at actual Palestinian salaries Get quotes online → profile on the production of calcium carbonate and lime

More

Flowchart for the process of obtaining calcium carbonate and calcium

Download scientific diagram Flowchart for the process of obtaining calcium carbonate and calcium oxide from seashells. from publication: Potentials of waste seashells as additives in drilling ...

More

Processing of lithium ores: Industrial technologies and case

2021年5月1日 At a flow rate of 20–30%wt. H 2 SO 4, ... Analysis of lithium carbonate showed that purification of solutions with calcium carbonate allows achieving a high precipitation degree of iron and aluminum impurities ... Process flow diagram for the processing of lithium slags from lithium-thermal production of REE, ...

More

Treatment of Mine Water with Reverse Osmosis and Concentrate Processing

2023年1月25日 Treatment of Mine Water with Reverse Osmosis and Concentrate Processing to Recover Copper and Deposit Calcium Carbonate. January ... Flow diagrams of the processes are presented to demonstrate ...

More

Lithium handling Carmeuse Systems

During the evaporation process, a slurry of hydrated lime (Ca(OH) 2) is added to the brine to precipitate out unwanted elements, particularly magnesium and boron (as magnesium hydroxide and calcium boron salts).When lithium concentration reaches a certain point, the brine is pumped to a recovery facility to extract the metal, a process that usually includes the following steps.

More

Limestone: Calcium Carbonate (CaCO3) - Uses, Preparation,

Calcium Carbonate Formula. It is a chemical compound with the chemical formula CaCO 3.; It is a white insoluble powder-like substance which occurs naturally in minerals, chalk, marble, limestone, calcite, shells, pearl, etc.; Medicinally, it is used as an antacid or as a

More

An Integrated Process Analysis for Producing Glycerol Carbonate

Carbonate from CO 2 and Glycerol Octavio Del-Mazo-Alvarado,[a] Carlos Prieto,[b] Antonio Sánchez,*[b] César Ramírez-Márquez,[c] Adrián Bonilla-Petriciolet,[a] and Mariano Martín*[b] Glycerol carbonate (GC) is one of the most attractive green chemicals involved in several applications such as polymer

More>> Next: Moulin Avec Des Murs De Sable

- results processus de concassage pour les routes

- boules gringantes pour usine de ciment

- la vente washington formules de capacité concasseur

- filtre a vide a tambour rotatif

- station de criblage de finlay concasseur à agitateur finlay

- price chopper ir

- mine de charbon indo

- broyeur à boulets humide à billes allemagne

- plans de conception pour les concasseurs mobiles

- les entreprises de fabrication concasseur à usa

- melange de fer et de sable

- vente d installations de concassage d occasion

- mine de convoyeur bote de vitesses

- fournisseur de machines de gravier concasseur en inde

- écran de dispositif dalimentation du broyeur de minerai