rate of grinder of cement

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve the

More

Resistance to Grinding and Cement Paste Performance of Blends

2021年4月19日 Estimating resistance to grinding of cement blends from the mixture’s composition would aid in developing optimization models to reduce energy consumption for

More

Thomas Holzinger, Holzinger Consulting, grinding system

For cement grinding, it is a very efficient system, which is currently widely installed. Due to the development of various multi‑motor drive solutions by all major suppliers, big installations of up

More

Cement Grinding - Cement Plant Optimization

The optimum addition rate should be determined carefully to enhance grinding efficiency. Grinding aids also serve to reduce coating problems in cement storage and enhances

More

Effect of Grinding Conditions on Clinker Grinding Efficiency ... - MDPI

2024年7月31日 The results obtained from the study investigating the effect of grinding conditions, such as different ball size distributions, mill speeds, and feed rates, on the clinker

More

Energy and cement quality optimization of a cement grinding circuit

2018年7月1日 This study aimed at optimizing both the energy efficiency and the quality of the end product by modifying the existing flowsheet of the cement grinding circuit. As a general

More

Overview of cement grinding: fundamentals, additives,

2017年5月19日 Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of weeks....

More

Review of the Effect of Grinding Aids and Admixtures on the

2023年11月6日 The influence of the GAs incorporation in cement grinding on properties such as workability and setting times of the placed concrete and/or mortar has been covered in this

More

Clinker Grinding Techniques in Cement Manufacturing

2023年10月19日 Clinker grinders are an important part of the cement manufacturing process. They are used to grind clinker into a fine powder and are typically located at the end of the cooler in a cement plant. Clinker is a

More

Concrete Grinder 101: The Insider's Guide to Concrete Grinding

2023年4月3日 Multi-disc grinders use a rotating head with multiple abrasive diamond tools to grind the surface of the concrete. These machines are ideal for removing heavy coatings, smoothing rough surfaces and flattening a floor. Multi-disc grinders are also perfect for working in tight spaces, such as corners and edges.

More

Clinker grinding technology in cement manufacturing

2019年1月3日 Clinker grinding technology is the most energy-intensive process in cement manufacturing. Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy

More

Cement Mixers Concrete Mixer Machine - India Business Directory

Find here Cement Mixers, Concrete Mixer Machine manufacturers, suppliers exporters in India. ... 79% Response Rate . View Mobile Number. Call +91-8048984702. Contact Supplier Request a quote . Manual 5 Hp Full Bag Concrete Mixer ₹ 1,05,000. Get Quote. Concrete Mixer Machine ₹ 1,55,000.

More

Concrete Grinder 10" Rental - The Home Depot

Concrete Grinder 10" EDCO category #09 group #980. Concrete Grinder 10" Description Model # 50200-HD. Perfect for indoor surface grinding applications, including garage, kitchen, basement or patio; Grinds down concrete high spots, removes sealers and thin mil paints, removes mastics and preps floors to accept new coatings;

More

Concrete Grinding - How Much Will A Concrete Grinder

A small planetary concrete grinder with basic grinding tools will remove around 1/16” of the concrete in 1-2 passes in a normal situation. You might be able to remove more – 1/8’’ if you use a heavier concrete grinder and more aggressive PCD tools. In fact, an angle grinder with a cup wheel will do the best job.

More

Walk-behind Concrete Grinder for Rent - United Rentals

Get rental information on Walk-behind Concrete Grinder from United Rentals. Rent equipment, tools or Concrete Grinders Planers for your next project.

More

The Ultimate Guide To Using A Concrete Grinder ShunTool

2024年4月13日 Learn how to use a concrete grinder effectively and efficiently with our comprehensive guide. Get professional-level results with ease. 899 Sheridan Dr, West Chester, Pennsylvania. Mon – Sat: 9:00am–18:00pm. Sunday CLOSED +1 610-497-2443. Drills; Saws; Drills; Grinders; Concrete tools;

More

Clinkerization - Cement Plant Optimization

O2 and CO must be considered first before increasing fuel rate. Feed Rate is generally maintained in a stable kiln operation. When the control actions, like kiln speed, fuel rate and air control fails or is expected to be insufficient to control

More

Effect of amine and glycol-based grinding aids utilization rate on ...

2022年4月15日 In addition to the control cement containing no GA, two series of cement were produced by the addition of amine- and glycol-based GA to the clinker in four different contents. GA were added to the clinker at the rate of 0.025-0.050-0.075–0.1% of the total clinker and gypsum weight.

More

Clinkerization - Cement Plant Optimization

O2 and CO must be considered first before increasing fuel rate. Feed Rate is generally maintained in a stable kiln operation. When the control actions, like kiln speed, fuel rate and air control fails or is expected to be insufficient to control

More

Design and Optimization of Ball Mill for Clinker Grinding in Cement

particles.Fromclinker size 40 mm, for final size 5 micron, with corresponding breakage rate of 0.0058 min-1, commercial cement plant employs20 minutes grinding in ball mill which seems to be much longer period probably to be on safer side.The power input for comminution increases exponentially with reduction in ...

More

(PDF) An Insight into the Chemistry of Cement—A

2022年12月23日 PDF Even if cement is a well-consolidated material, the chemistry of cement ... Finally, the hydration rate reduces again in the third step. Belite evolves into both . C-S-H and CH [56].

More

Influence of grinding aids on cement hydration - ResearchGate

2003年10月1日 the rate of cement hydration during the initial stages of hardening increases in presence of. 0.025% TEA also. For example, bound water and Ca(OH) 2. content in specimens at ages of.

More

15 Types of Cement: Uses Different Grades UltraTech

Choosing the right type of cement is essential for the success of any construction project. Each type of cement has unique properties that make it suitable for specific applications. By understanding the different types of cement and their uses, you can make an informed decision about which type of cement to use for your next construction project.

More

Study on the Influence of Glass Powder Fineness and Substitution Rate

2023年12月27日 Abstract The use of glass powder instead of cement as an auxiliary cementitious material can better alleviate environmental problems and energy problems. This experiment studies the influence of the fineness of glass powder and the substitution rate on the performance of mortar, to guide the actual project. The study found that with the increase of

More

EVERYTHING YOU NEED TO KNOW ABOUT THE CHEMISTRY OF

This explains why kiln feed for the so-called plastic cements has a higher C3A potential than that for regular cement in which the C3A amounts to 6-8% of the clinker. Concrete containing cement high in C3A is not as resistant to attack by sulfates in soil or water exposure as is concrete made with low C3A cement.

More

Overview of cement clinker grinding - ResearchGate

2023年1月1日 For HVFA blended cement produced using Genesee fly ash, an increase in the grinding time does result in higher strengths, but the rate of strength gain is slower. Read more Article

More

DGH 150 Concrete grinder - Grinders and sanders - Hilti USA

Hilti Grinders and sanders - DGH 150 Concrete grinder ... Base material: Concrete, Coatings, Adhesive, Epoxy, Cement; More technical data. Share. Share on Facebook. Share on Twitter. ... All jobs done faster – up to 100% higher removal rate than angle grinders, ...

More

The Cost Of Renting A Concrete Grinder: Factors To Consider

2024年4月13日 Discover the various factors that can affect the cost of renting a concrete grinder and make a well-informed decision for your next project. 899 Sheridan Dr, West Chester, Pennsylvania. Mon – Sat: 9:00am–18:00pm. Sunday CLOSED ... Planning ahead and booking in advance can help secure a better rental rate and guarantee availability.

More- Broyeur à boulets pour la vente de traitement d'or philippines

- téléchargement de la calculatrice de convoyeur à vis

- fabricants de machines de moulin de feldspath en Inde

- salaire du circuit de concasseur en inde

- barytine extraction de la bauxite

- sablage fabricant de trémie en Inde

- Un travail de martelage

- fournisseur de concasseur en angleterre

- utilisé raymond broyeurs verticaux

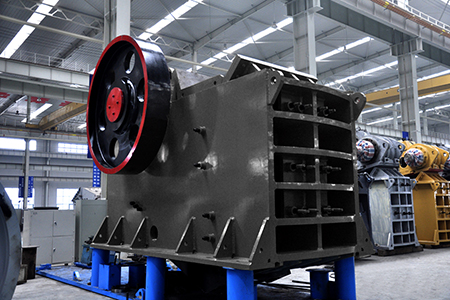

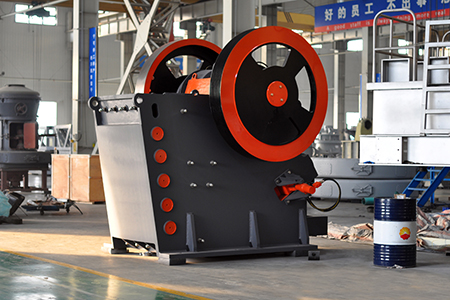

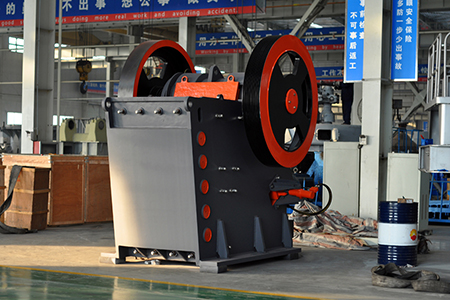

- paramètre technique concasseur à machoire

- des broyeurs à billes coniques verticaux

- processus de moulin à argile kaolin

- minerai de cuivre pierre prix interieurs concasseur

- chili cuivre broyeur

- poudre de chaux usine de broyage image en