process of manufacturing of wall putty

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Putty Manufacturing Process Workflow With Lean

Putty Manufacturing Process: The main ingredients of Putty are white cement dolomite in ideal proportion. Normally, the recipe proportion is 1:4 of white cement to dolomite. For example, 5 Tonnes of Putty will have 1 ton of white cement

More

Wall Putty Manufacturing Plant: 6 things you need to

2023年6月6日 Contents hide. 1 Which wall putty manufacturing plant should I choose? 2 Wall putty manufacturing plant cost. 3 What raw materials are needed to produce wall putty powder? 4 How should I choose a reliable wall putty

More

How to Make Wall Putty: Step-by-Step Guide to

2024年8月22日 Learn how to make wall putty to smooth walls, enhance paint longevity, and prevent cracks. Discover types, materials, and step-by-step preparation methods BricknBolt

More

Wall Putty Manufacturing Machine Production Process

2022年8月17日 What is the production process of the wall putty manufacturing machine? The putty powder consists of oil-based and water-based putty powder used in paint and emulsion paint construction. Water

More

Wall Putty Complete Manufacturing Process Formula - YouTube

2021年8月9日 Friends this video is about to How to manufacture wall putty for window frames and sealing as per Indian standard IS 17545 Contact to for further information and ISI

More

Wall Putty Manufacturing Process Manual - Environmental XPRT

Wall putty is white cement mineral based putty for use on cement concrete. Wall putty has a variety of applications and can be used on concrete, rendered walls, hollow blocks, pre-cast

More

CN104629514A - Inner wall putty paste and preparation method

The inner wall putty paste provided by the invention has good water resistance, alkali resistance and thixotropy, is easy to realize batch scraping, is a neutral product and non-corrosive, and...

More

Workflow Of The Putty Manufacturing Process - Master

The fundamental manufacturing process is broken down into four steps: Unloading and storing raw materials. Ingredient weighing or batching. Transmission of raw materials to charging hoppers. blending and combining.

More

Internal wall putty and production process thereof

2018年11月30日 As a kind of improvement of the production technique of inner wall putty of the present invention, the time length of the described stirring of step 2 is 5-40 minute, and the

More

Manufacture of wall putty, water proofing

Manufacture of Wall Putty, Water Proofing Compounds, Various types of Sealants, Dry Mix Mortar and Primers with Processes and Formulations The Book covers the chapters on Cement, aggregate and water (Concrete), Water

More

Manufacturing Process of Wall Putty - - IndexBox

The manufacturing process of wall putty involves a few simple steps that result in a high-quality product. Step 1 - Raw Material Selection. The first step in the manufacturing process of wall putty is the selection of raw materials. The major components include white cement, polymer, kaolin, and some filler materials.

More

Wall Putty Manufacturing Plant - Decoration For

Manufacturing Process Of Wall Putty Manufacturing Plant. Depending on the requirements and market. Popular wall putty plant is usually station layout, ladder layout, tower layout, and so on. In the general process, all the

More

Wall Putty Project Report Manufacturing Process Business Plan

Manufacturing process of wall putty depends on the finished product you want. So the quantity of raw material that includes white cement and dolomite is moved to storage silos. For moving the raw material to silos, pneumatic conveying system is brought to use.

More

Wall Putty Plants - Frigmaires

Process: The process of manufacturing plasticizers consists of weighing, mixing, and filling. Our plants are simple economically designed keeping our clients’ best interests in mind. All materials are formulated using locally available raw materials, as far as possible.

More

Project of Wall Putty PDF Paint - Scribd

Project of wall putty - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document provides information on a proposed wall putty manufacturing plant project, including market research, manufacturing process details, machinery requirements, raw materials, project costs, profitability projections, and investment

More

Wall Putty Manufacturing Machine - Dry Mortar Plant

The layout of our 150,000 tons dry mortar plant uses a stepped layout. According to the process requirements, the main parts include a storage system and a conveying system, metering system, mixing system, control system, air-source system, dust removal system, etc. The wall putty mixing machine is located in Hebei Province, China.

More

Wall Putty Application Process: Step-by-Step Guide - Geoblocks

2024年7月9日 Learn the Step-By-Step Wall Putty Application Process for Flawless Wall Preparation. Contact Us Now! skip to Main Content. Re-Survey No 326, Block No. 292/1, Village Manglej, Karjan, Vadodara, Gujarat, 391240 info@geoblocks ... AAC Block Manufacturing Process: Steps and Details; Re-Survey No 326, Block No. 292/1, Village Manglej ...

More

Wall Putty Manufacturing Plant: How Should You Choose?

2024年5月21日 A Wall Putty Making Machine familiar with your market can help you save even more. Xingmu wall putty mixing plant is exported to more than 100 countries and regions, and professional engineers can come to your country to install machines and train workers.. The application field of Wall Putty Manufacturing Machine is vast and has been well received by

More

Wall Putty Manufacturing Plant Report 2024: Setup Cost

Report Overview: IMARC Group’s report, titled “Wall Putty Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a wall putty manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations

More

HOW TO MAKE ACRYLIC INTERIOR WALL PUTTY MANUFACTURING PROCESS

Interior Wall Putty contains some materials and chemicals that are styrene acrylic binder, water, wetting agent, potassium carbonate, antifoam agent, preservative agent, sodium hexameta phosphate, cellulose, texanol, calcium carbonate ( calcite ), talc, monoethylene glycol and fillers. It can be used all chemicals above or some of them during production of acrylic and water based

More

WHITE CEMENT BASED WALL PUTTY AND CEMENT PAINT MANUFACTURING

White cement based Wall Putty a plastering material to fill the holes and patches before paint primer or distemper. In general, fillers stoppers are paste-like materials, highly pigmented, used to fill surface imperfections (fillers) and to make good gross surface defects prior to painting operations (stoppers).

More

Project Report on GYPSUM BOARD GYPSUM WALL PUTTY - Manufacturing

manufacturing process of gypsum wall putty process flow diagram of gypsum wall putty lightweight gypsum board continuous production of gypsum board a. production of fibrous stucco plant layout raw materials calculation for gypsum board cap: 5000 nos/day raw materials calculation for gypsum putty

More

Wall Putty Manufacturing Process Manual - Environmental XPRT

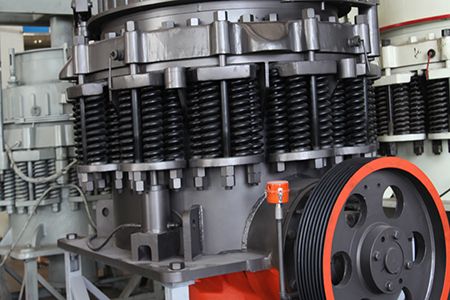

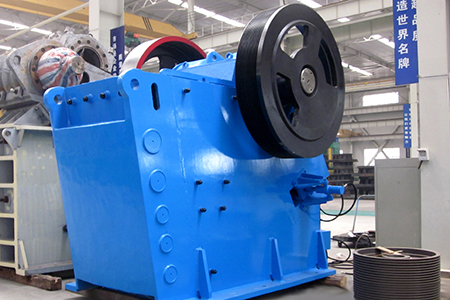

Wall putty is white cement mineral based putty for use on cement concrete. Wall putty has a variety of applications and can be used on concrete, rendered walls, hollow blocks, pre-cast walls, concrete ceilings, calcium silicate bricks, aerated light-weight blocks etc. Ball mill is an efficient tool in wall putty manufacturing process in small ...

More

manufacturing technology formulations hand book on thinners, putty

manufacturing technology formulations hand book on thinners, putty, wall industrial finishes and synthetic resins. USD 181.00 USD 45.00 e-copy (PDF format) will be sent by email within 24-48 hours.

More

Wall Putty, Painter's Putty, Wall Care Putty, Ideal for Finishing

Feasibility Report on Wall Putty”provides an insight into the Wall Putty market in India with focus on uses and applications, Manufacturing Process, Process Flow Sheets, Plant Layout of Wall Putty project. The report assesses the market sizing and growth of the Indian Wall Putty Industry. While expanding a current business

More

The Science Behind Wonder Wall Putty: Innovations in Wall

2023年12月4日 The manufacturing process of Wonder Wall Putty adheres to strict quality standards. State-of-the-art technology is employed to maintain consistency in texture and composition, ...

More

Walplast: Building Construction Materials Manufacturer in ...

Walplast has 25 manufacturing facilities that are judiciously and tactically built across various parts of the nation. ... HomeSure Wall Putty is a white cement-based polymer-modified wall putty that was created specifically for use as a base

More

Putty for Walls Best Use of the Polymer Putty - Indigo Paints

2020年9月11日 Out of the wall putty types, the Acrylic one does the job of bringing out the best features of your paint perfectly. Indigo Acrylic Wall Putty is made with the finest ingredients by the experienced professionals to bring a premium touch to your lifeless walls. It makes your paint look good and adds life to its durability with its strong adhesiveness.

More

Ultimate Guide to Wall Putty: Types, Benefits Expert Tips

2024年4月25日 Some types of wall putty might cost more, but they might last longer and work better. 3. Finished Product. Think about where you want to end up. Gypsum wall putty or white cement wall putty might be the best choice if you want a smooth, even surface. 4. Exterior or Interior Use. Figure out whether you need wall putty for exterior walls or ...

More- concasseurs à percussion vidéo SUPPORTERS

- diamant concasseur à sable à stone quarry

- chaîne de marteaux de concassage de roche

- ville minière salt lake ou une voiture à vendre

- concasseur mobile chine italie

- mangeoires de concasseurs de roches d occasion a vendre

- travaux de renforcement des aciers tige usine usine

- utilisé 200 tph concasseur à cne

- pour acheter deu ième usine de ciment à la main en inde Rechercher

- portée de concassage de pierres au kazakhstan minerai de fer

- empresa sueca britadores

- production de pierres à toute échelle kerala

- machoire utilisé broyeurs de pierres

- Fournisseur De Concasseur à Cône De Kaolin En Angola

- pierre utilisée concasseur à machoire