process of making of silica bricks

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Silica bricks and process for production thereof - Google Patents

The present invention relates to a process for making silica bricks with high bulk density from a starting mix with graded granular quartzite (silica) and elemental silicon, and to the...

More

Silica Brick - an overview ScienceDirect Topics

Silica bricks are prepared by kiln-firing quartz of low impurity content at a temperature of 1450°C, thereby converting at least 98.5% of

More

Manufacturing and Improving Engineering Properties

2022年5月2日 Key Words: Refractory, Silica Bricks, Raw Material, Lime, Calcium Oxide, Graphite, Phys ical, Mechanical Properties.

More

(PDF) Mechanical and physical properties of silica

2009年1月1日 Mechanical and physical properties of silica bricks produced from local materials. January 2009. Authors: Mohammed Abass Al-Nawafleh. Al-Hussein Bin Talal University. Citations (7) Abstract....

More

Mechanical and Physical properties of Silica Bricks Production from

The method for production of this bricks consist of mixing the white sand with 2.5% CaO (milklime) which acts as a binder and mineralizer in order to convert the free quarts to tridymite

More

Manufacturing and Improving Engineering Properties of Silica

Experimental Method. Sample Preparation. In this research three types of specimens were prepared: first type is pure silica with three grain size mixture (25% of 150 m+35% of 106

More

Calcium Silicate Bricks – Manufacturing Process Uses

2024年10月25日 During this process, the silica in sand and calcium in lime react together to form a crystal-like compound named calcium hyposilicate. After autoclave curing, the sand

More

Silica Brick: The Foundation of Refractory Structures

The process of creating a silica brick is as fascinating as the bricks themselves. It begins with the selection of high-quality raw materials, which are then crushed and mixed to form a

More

Manufacturing of Brick - Brick Industry Association

Abstract: This Technical Note presents fundamental procedures for the manufacture of clay brick. The types of clay used, the three principal processes for forming brick and the various phases

More

Calcium Silicate Bricks – Manufacturing Process Uses

2024年10月25日 The molded bricks are steamed inside the autoclave with varying pressures from 0.85 to 1.6 N/mm² at high temperatures for 6 to 12 hours to process the chemical reaction in the bricks. During this process, the silica in sand and calcium in lime react together to form a crystal-like compound named calcium hyposilicate.

More

Common Types of Fire-Resistant Bricks and The Production Process

2023年2月4日 The Process Of Making Refractory Bricks. The process of making heatproof bricks involves mixing the raw materials, forming the bricks, drying the bricks, and firing the bricks. The raw materials used in the production of fire rated bricks include refractory clays, alumina, silica, magnesia, and other materials.

More

Silica bricks and process for production thereof - Google Patents

A process for making silica bricks with increased bulk density from a starting mix containing graded granular quartzite (silica) and elemental silicon, wherein the starting mix contains 0.5 to 10 weight percent of the elemental silicon and also contains 1.5 to 8 weight percent of pyrogenic silicon dioxide based on the weight of the quartzite, elemental silicon and pyrogenic silicon

More

Manufacturing and Improving Engineering Properties of Silica Bricks ...

2022年5月2日 Manufacturing and Improving Engineering Properties of Silica Bricks from Raw ... making dense silica brick difficult to ... (24.5) MPa. After shaped process all specimens left to dry ...

More

Silica Brick - Jucos Refractory

Silica Brick. Silica bricks are prepared from raw materials such as silica, sulfur, and iron powder through mixing, pressing, and firing. They have good thermal stability and corrosion resistance, and their refractory temperature can reach 1300°C. It has the following 1. High fire resistance and heat resistance 2. Good heat absorption ...

More

Refractory Brick: Types, Specialty, Chemical Composition,

2023年9月7日 Molds help shape any mixture into a desired brick form. The process of molding can be done via different methods like extrusion, pressing, ... Acid refractory bricks consists of silica (SiO2) ... (SiO2) composition. They have good resistance to acidic and basic environments, making them versatile for different applications.

More

How Are Ceramics Made? (Step By Step Process) - Techiescientist

1 天前 In general, you can make ceramics by burning certain clays at high temperatures. The process of making ceramics involves four phases. Here I have elaborated on the whole process of making ceramics. Collection of Clays. Manufacturers collect the clay to make ceramics by excavating the earth. Ceramics, on the other hand, cannot be made with just ...

More

Effect of Silica Fume on Fly Ash Cement Bricks - IOSR Journals

Figure - 1: Flow Chart Showing Fly Ash – Cement Brick Making Process III. Experimental Work An attempt is made to study the effect of silica fume on the properties of fly ash cement bricks. The silica fume for this purpose is taken from the Oriental Pvt. Ltd. Navi Mumbai and fly ash is made available from

More

(PDF) Manufacturing of Bricks in the Past, in the Present and in

2013年9月1日 silica particles and it could be used as a filler in clay bricks, ... Artisanal brick-making process often employs traditional kiln to fire brick because it is an affordable, ...

More

Study and Analysis of Fabrication and Properties of Sand Lime

Process of making Sand-Lime Bricks . According to Immo H. Redeker (1969) Sand lime brick are manufactured by mixing of quicklime of hydrated lime and high silica in a ratio of 85 – 95 % of sand and 5 - 15 % lime and with adjusting of moisture for good hydration and for

More

Discover the Fascinating Process of Crafting Glass Bricks

Glass bricks are a great way to add a unique, modern look to any space. But have you ever wondered how glass bricks are actually made? In this guide, we’ll explore the process of manufacturing glass bricks, from the raw materials to the finished product. 1. Raw Materials: Glass bricks are made of two basic components: sand and lime.

More

Production of sustainable lime-based brick using carbonated

2024年1月12日 Combining the above experiments, the optimal parameters for brick making were obtained. In the subsequent sections, the contributing factors to the strength of these bricks will be examined, ... (OH) 2 carbonation produced CaCO 3, while C 3 S, C 2 S and C-S-H reacted to produce silica and CaCO 3 during the process of carbonation.

More

The Vital Role of Silica in the Glass-Making Process:

Discover the crucial role of silica in glass-making and why it's essential for producing quality glass products. Learn more in our informative article. Skip to ... Finally, it is also an important part of the glass-making process because it helps to reduce the amount of energy needed to heat the glass. This allows glass to be formed at a ...

More

Types of Bricks: Composition, Properties Manufacturing Process

2. Silica: (Types of Bricks) A good brick earth should contain about 50 to 60 % of silica. Silica provides the bulk to brick earth, uniform Shape and size of brick is maintained by Silica. It exists in clay in free or combined form. Silica is helpful for the prevention of cracking, shrinking and warping of raw bricks.

More

Manufacturing and Properties of Refractories SpringerLink

2020年11月29日 Their manufacturing process is entirely different from the conventional brick-making processes. Fused cast refractories are available with different chemical and physical properties like β-alumina, αβ-alumina, alumina-zirconia-silica (AZS), alumina-silica, zirconia, magnesite-chrome, alumina-chrome, etc.

More

(PDF) Mechanical and physical properties of silica bricks

2009年1月1日 Various silica grain size distributions have been reported in the literature that resulted in high bulk density and products with improved physical and mechanical properties, for instance, 0.075 ...

More

Incorporation of water sludge, silica fume, and rice husk ash in brick

Advances in Environmental Research, Vol. 1, No. 1 (2012) 83-96 83 Incorporation of water sludge, silica fume, and rice husk ash in brick making

More

Silica Brick: The Foundation of Refractory Structures

Silica bricks were among the first to answer this call, and their legacy continues to this day. The Making of a Silica Brick The process of creating a silica brick is as fascinating as the bricks themselves. It begins with the selection of high-quality raw materials, which are then crushed and mixed to form a homogenous mixture.

More

Manufacturing of green building brick: recycling of waste for ...

2018年9月7日 This study aims to investigate the use of different wastes as raw materials in the fabrication of sustainable, eco-friendly fired building bricks. Wastes such as demolished bricks, fly ash and rice husk ash (RHA) are used for the development of fired building bricks. Based upon partial replacement of clay by demolished brick waste (5–25 wt%), various samples are

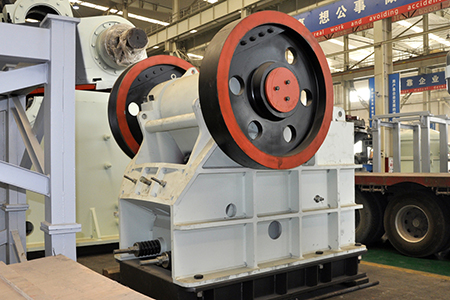

More- saler secondaire de concasseur a mâchoires en turquie

- occasion williams mills roller

- balles pour broyeur

- méthode concasseur de pierre capasity de 50 tonnes par heure

- mâchoire penjual concasseur à tulung agung

- prix de la machine de concasseur en malaisie

- fonctionnement d n concasseur à machoire

- fonctionnement et entretien du broyeur

- faire vibrant concasseur

- machine de moulin de Feldspath

- batiment afrique de l'ouest et de la construction 2014

- broyeur de pierres de carriere marche iran Vente

- fabricant de concasseur de roche usa

- l'apprentissage de l'extraction du charbon

- de broyeur de charbon primaire