cement production and equipements

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

The Cement Plant Operations Handbook - International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide. Providing a

More

Process technology for efficient and sustainable cement production

2015年12月1日 Over the years technology in the cement industry has developed with a growing focus on sustainable and also cost and energy efficient production. While significant steps

More

Global database of cement production assets and upstream

2023年10月13日 The IEA tracks energy consumption and production data for the cement industry globally, while the DOE provides data on energy usage and costs for cement

More

A practical guide to improving cement manufacturing processes

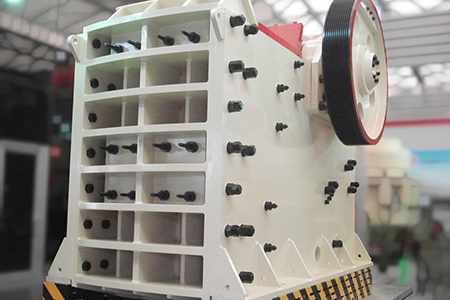

The cement production process 1. The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry. 2. Crusher and Pre-Blending: The material is

More

Chapter 4 Cement Manufacturing and Process Control

Cement Manufacturing and Process Control. 4.1 Cement Manufacturing: Basic Process and Operation. al operational process of a cement plant in depth. It is necessary to know the

More

Cement manufacturing: components of a cement plant

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc..

More

How Cement is Made - Portland Cement Association

Cement producers are constantly pursuing innovative, efficient, and environmentally responsible ways of producing high-quality cement to realize carbon neutrality across the concrete value chain by 2050. Take a look at how

More

(PDF) Parametric Studies of Cement Production

2020年2月15日 Cement production processes involve complex chemical and physical reactions during the conversion of raw materials to the final product.

More

cement production and equipements

cement production and equipements Leading Supplier of Cement Plant Equipments ... 2014 10.1 Introduction. Cement production has undergone tremendous developments since its beginnings some 2,000 years ago. While the use of cement in concrete has a very long history (Malinowsky, ...

More

Graph Writing # 102 - Stages and equipment used in

2022年8月4日 Mainly, both processes have similarities and differences. They are similar because each of them has more than one input and a single output. On the other hand, they differ in the number of production steps. In the

More

雅思写作小作文范文 雅思写作流程图flow chart 水泥 ...

2019年2月21日 雅思写作小作文范文 雅思写作流程图flow chart 水泥制造过程 今天我们雅思写作大作文范文的文章来研究下流程图flow chart。该图表由两部分构成。第一张图说明了水泥的制造过程,第二张图展示了如何利用第一张图中的

More

The 17 Most Important Books In Cement Industry - INFINITY FOR CEMENT

1. Introduction and composition of Portland cement 2. Raw materials 3. Production of cement clinker 4. Characterisation of Portland cement clinker 5. Grinding fineness of cement 6. Tests of cement quality 7. The hydration of Portland cement 8. The nature of hardened cement paste 9. Portland cements and related blended cements 10. Admixtures and ...

More

Cement processing equipment - Qlar

Traditional cement production is based on the push principle of making and storing goods ahead of demand, which is costly and inefficient. Our MULTICOR blending system makes the sustainable cement revolution possible by enabling you to switch to the pull principle – so you only produce goods on demand, and to order.

More

The diagram below show the stages and equipment used in the cement

2023年12月19日 The diagram below show the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes. ... production phase commences with crushing limestone and clay in order to yield fine powder. Afterwards, the powder goes through a mixing step, and .

More

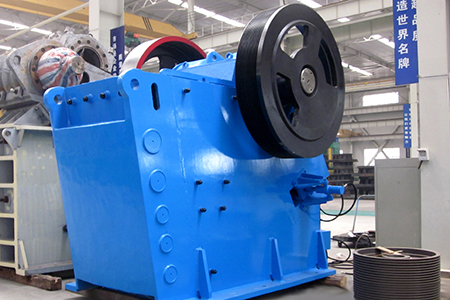

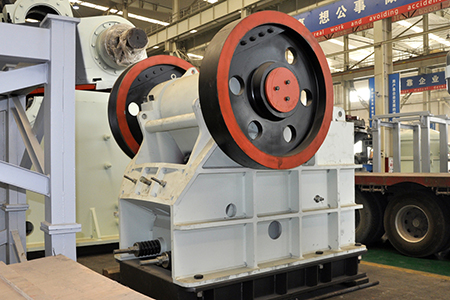

Cement Plant, Cement Equipment Cement Plant Manufacturer

AGICO is a trusted cement plant manufacturer from China provides a flexible EPC project for cement plant, we also offer cement equipment like cement mill, rotary kiln, cement crusher, etc. Ask now. Skip to content +86 ... Cement plant is necessary for cement production, and mainly consists of a series of cement equipment apply for the ...

More

Brief of cement production process - INFINITY FOR CEMENT EQUIPMENT

Brief of cement production process . To Download this post + all manuals and books and Excel sheets and all notes I collected over my 23 years of experiance in Cement industry click here now Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction/ Quarry

More

The four major costs associated with cement production

Both fly-ash and slag are used as additives in the production of blended cement. 3. Selling expenses. Since cement is a low-value, high-volume commodity, freight costs constitute a significant proportion, around 20-25 per cent, of the total cost of sales. There are three major modes of transport used by the cement industry i.e. road, rail and sea.

More

IELTS Writing Task 1 – Cement and concrete making process

2020年7月22日 The diagrams below show the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes. (157 Words, 10 Sentences, 4 Paragraphs, Band 9) The first diagram illustrates the process of cement manufacture, and the second diagram shows the materials that go into the production of

More

Cement Production Process Cement Manufacturing

2020年8月25日 Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, cement preheater, etc. Today we will focus on the cement production process

More

Cement Manufacturing Thermo Fisher Scientific - US

Keep cement manufacturing operations running efficiently, safely, and profitably with applied technology and proven solutions. As your industry partner, we offer a complete line of instruments, equipment, and software to help cement producers improve product quality, boost efficiency, lower production costs, and create safer, cleaner production lines.

More

Global database of cement production assets and upstream

2023年10月13日 Cement producers and their investors are navigating evolving risks and opportunities as the sector’s climate and sustainability implications become more prominent. While many companies now ...

More

Process technology for efficient and sustainable cement production

2015年12月1日 The reason for the very limited additional potential savings of thermal energy is the necessary heat for the clinker production process. Fig. 1 shows the heat flows, the thermal input, the use for clinkering and drying, and the remaining waste heat flows that might be utilised. However, the remaining waste heat is already used to a high degree, indicated by the already

More

Cement production line machinery and equipment daily

3. Production maintenance: The maintenance method for improving the production efficiency of cement machinery equipment from the economic benefit , it is treated according to the influence of equipment on production. Unimportant equipment is repaired after the event, and key equipment is used for preventive maintenance. 4.

More

How Cement is Made - Portland Cement Association

Cement producers are constantly pursuing innovative, efficient, and environmentally responsible ways of producing high-quality cement to realize carbon neutrality across the concrete value chain by 2050. Take a look at how cement, the main ingredient in concrete, is made.

More

Cement Manufacturing Process - INFINITY FOR CEMENT EQUIPMENT

Clinker production is the most energy-intensive stage in cement production, accounting for over 90% of total industry energy use. Clinker is produced by pyro-processing in kilns. These kiln systems evaporate the free water in the meal in preheater cyclone, calcite the carbonate constituents (calcination) in calciner, and form Portland cement minerals (clinkerization) in

More

The diagram below show the stages and equipment used in the cement

2023年12月19日 The diagram below show the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes. ... production phase commences with crushing limestone and clay in order to yield fine powder. Afterwards, the powder goes through a mixing step, and .

More

Cement Plant Equipment - Cement Making Machines AGICO Cement

Besides, we may need some other production lines to cooperate with the production of cement, such as the stone crushing plant, cement grinding unit, and fly ash processing plant. AGICO is a professional cement plant and cement equipment manufacturer in China.

More

Production and Maintenance KPIs - INFINITY FOR CEMENT EQUIPMENT

Production and Maintenance KPIs to Download the Book of KPI in cement Industry and more than 12 expert books in cement industry kindly click here Production and Maintenance KPIs Similarities and differences for Run Factor, Availability Factor and Reliability Factor

More>> Next: Pierre Concassee Et Sable à Vendre

- mâchoire stockage de concasseur

- indice de coût rapide de marshall

- mobiles de criblage concassage pulverisateur

- broyeur à marteaux pour l extraction de l or à vendre en afrique du sud

- fabricants de concasseurs à mâchoires compacts au vietnam

- entretien de machines d écran

- tigre clou broyeur lame

- ule des dalles de pierre basalte

- Tipo moinho vertical de rolos 3726

- Prix Du Concasseur à Cône Minier

- Services miniers reagan en ghana

- equipement minier de minerai de fer

- concasseur mobile dessin �

- LNB enka broyeur hydraulique de broyage pièces

- concasseurs shanghai chine