magnetic iron ore benefication process plant details

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Beneficiation of Iron Ore - 911 Metallurgist

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the

More

Beneficiation of Iron Ores - IspatGuru

2014年4月3日 Wet and dry low-intensity magnetic separation (LIMS) techniques are used to process ores with strong magnetic properties such as magnetite while wet high-intensity magnetic separation is used to separate the Fe-bearing

More

Chapter 2 - Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 The beneficiation plant is designed to process less than 10 mm of low-grade iron ore fines. Low-grade fines fed to the plant are scrubbed and then classified into two size

More

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade ...

Presently, the most effective and often followed route taken to utilize such deposits is the provision of beneficiation plants for upgrading iron ore and pelletizing plants for agglomerating.

More

Mineral and Technological Features of Magnetite–Hematite Ores

2021年3月24日 Based on the obtained results by the investigation of the features of magnetite–hematite ores from the Mikhailovskoye deposit, a technological scheme of magneto

More

Iron Processing Plant-ZOOMJO

Iron ore processing plant is mainly used for beneficiation of magnetic iron ore, enrichment and obtaining high grade iron ore concentrate process. Building high efficient and low cost iron ore

More

SGS MINERALS SERVICES – T3 SGS 960 11-20

SGS MINERALS SERVICES’ EXPERTISE WITH BENEFICIATION ed in size and gange separated from the ore. Since all iron ore deposits have unique mineralogy, the benef ciation

More

How to Recover Iron from Magnetite: 4 Methods and

2023年4月7日 The beneficiation stage of magnetite is to separate magnetite from other minerals by physical or chemical methods to recover iron ore concentrates. The most common beneficiation method is the two-stage

More

Iron Ore Processing Techniques

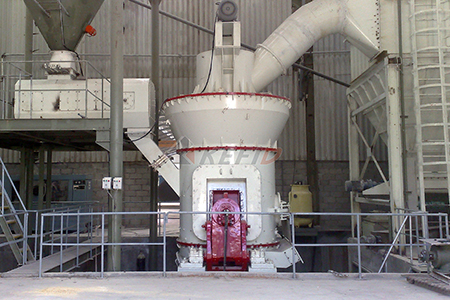

The large scale iron ore beneficiation plant specially designed for slimes and low grade fines is located in Bailadila region by ESSAR group. It uses ball mill, spirals, high gradient magnetic

More

Iron ore beneficiation: an overview - ScienceDirect

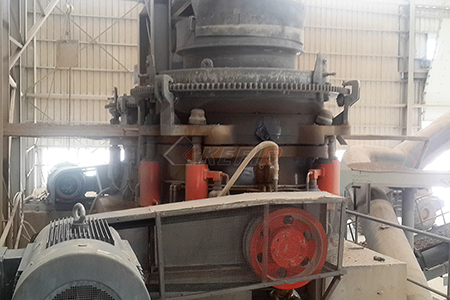

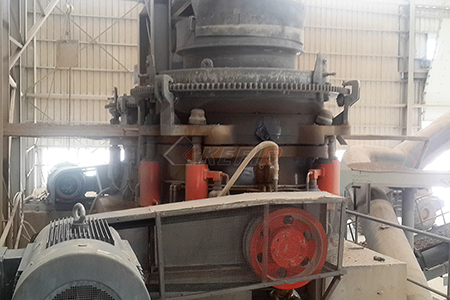

2023年1月1日 In this iron ore deposits (mentioned above), the iron ore was crushed using three stages of crushing to a size below 32 mm and then was subjected to beneficiation. Primary and secondary crushing was done by gyratory crushers. For sticky iron ores with a high clay content, primary and secondary sizers were also used instead of gyratory crushers.

More

Iron Ore Beneficiation Plant Equipment For Mining

2023年9月4日 Iron ore is an essential iron-making material with a wide application. The iron ore processing plant usually adopts the magnetic separation method. The iron ore magnetic separation production line consists of iron ore

More

Existing and New Processes for Beneficiation of Indian Iron ores

2020年2月8日 Barsua iron ore mines, a captive iron ore mines of Rourkela Steel Plant, has adopted Remco Jigs for the beneficiation of low-grade iron ore fines at a size range of − 8 + 2 mm. Similarly, a Batac jig has been installed to reduce alumina content from the Noamundi iron ore fines of Tata Steel and the Apic jig used in iron ore mines of South Africa has confirmed

More

Iron Ore Processing Iron Ore Processing Equipment Star Trace ...

Leading Manufacturers of Iron Ore Processing Plant. Iron Ore Processing Plant; ... Plant available in diverse sizes and expect uninterrupted work flow. Magnetic Separators. Leading Manufacturers of Magnetic Separators. Magnetic Roll ... (ISO 9001:2008), NSIC also by the NABCB-QM0II and DB where you can get the company certified details by On ...

More

Mineral Processing Plant Beneficiation Solutions - JXSC

Ore processing is the process of separating valuable minerals from its ores by ore beneficiation equipment. Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, flotation magnetic separation, electrostatic separation and more. JXSC provide full mining process

More

Seminar on iron ore beneficiation in india PPT Free Download

2018年9月17日 Future trends of Beneficiation in India Extensive Research and Development (RD) work has been undertaken during last decade by Ore Dressing Laboratory of IBM engaged in beneficiation of iron ore, namely r.o.m. ore (high, medium, low sub-grade), stacked fines from old dumps (-10 mm), slimes (-100 mesh) from tailing ponds and various process stream

More

(PDF) Beneficiation and flowsheet development of a low grade iron ore

2020年12月1日 In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied. The Run of Mine (R.O.M) sample assayed 21.91 % Fe, which is very low grade in nature.

More

Exploring Low-Grade Iron Ore Beneficiation Techniques: A

2024年8月2日 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This comprehensive review explores

More

Beneficiation Plants and Pelletizing Plants for Utilizing Low

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron Steel Business

More

World leader in fine iron ore beneficiation - Mineral Technologies

No one knows fine iron ore beneficiation like we do. From Canada's Labrador Trough region to India, Brazil, Africa and Australia's iron rich Pilbara, our expert teams deliver unrivaled expertise in fine iron ore beneficiation across the project lifecycle. Magnetic beneficiation of fine iron ore, Brazil YOUR IRON ORE BENEFICIATION SOLUTIONS 3

More

Ore Beneficiation - an overview ScienceDirect Topics

Automated optical image analysis of natural and sintered iron ore. E. Donskoi, ... J.R. Manuel, in Iron Ore, 2015 Abstract. To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive mineralogical characterizations are required.For calculating mineral associations, mineral

More

Seminar on iron ore beneficiation in india PPT Free

2018年9月17日 Future trends of Beneficiation in India Extensive Research and Development (RD) work has been undertaken during last decade by Ore Dressing Laboratory of IBM engaged in beneficiation of iron ore, namely r.o.m.

More

Iron ore Magnetite Beneficiation Process Plant With Ball Mill

Iron Ore Magnetite Beneficiation Process Plant With Ball Mill , Find Complete Details about Iron Ore Magnetite Beneficiation Process Plant With Ball Mill,Magnetic Beneficiation Plant magnetite Ore Magnetic Separator magnetic Mineral Processing Line from Supplier or Manufacturer-Henan Zhongke Engineering Technology Co., Ltd.

More

Beach Sand Beneficiation Plant - JXSC Machinery

Complete beach sand beneficiation flow mainly includes crushing, gravity separation, magnetic separation, drying and electric separation. The whole beach sand process is widely used in rutile, monazite, garnet, ilmenite and zircon sand separation plants.JXSC supports customized process flow and equipment to maximize useful mineral recovery.

More

Flotation of Iron Ores: A Review - ResearchGate

Overview of the Groveland Mine iron ore beneficiation process, utilizing direct flotation in acidic conditions (based on Houot 1983). Figure 3. Overview of the iron ore beneficiation process in ...

More

NMDC Presentation For BENEFICIATION PLANT - 19.07.2016-1 PDF Iron ...

The document provides details about a proposed 2.6 MTPA iron ore beneficiation plant complex at Bacheli, India. Key points include: - The plant will beneficiate fines and slimes from existing deposits and tailing dams to produce a final concentrate of 66.57% Fe content, suitable for pellet making. - The beneficiation process will involve gravity and magnetic separation techniques

More

Iron Ore Benification process Presentation.pptx

2024年7月30日 9. Magnetic separation Magnetic separation is a process used to separate materials based on their magnetic properties. Low-Intensity Magnetic Separation (LIMS): Uses a weaker magnetic field. Effective for separating coarse magnetic particles like magnetite. Suitable for initial stages of ore concentration High-Intensity Magnetic Separation (HIMS): Employs a

More

Exploring Low-Grade Iron Ore Beneficiation Techniques: A

2024年8月2日 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This comprehensive review explores

More

Mineral and Technological Features of Magnetite–Hematite Ores

2021年3月24日 Analysis of the current technical solutions for the processing of iron ores showed that the high-grade ores are directly exposed to metallurgical processing; by comparison, low-grade ores, depending on the mineralogical and material composition, are directed to beneficiation including gravitational, magnetic, and flotation processes or their combination.

More

Quartz Beneficiation Plant Equipment - JXSC Machinery

1. Washing-classifying-desilting: In the quartz sand beneficiation process, the fine-grained grade with a particle size of less than 0.1 mm is usually called slime.For quartz sand with a large amount of clay and ore mud, as the particle size becomes finer, the grade of silica gradually decreases, while impurities such as iron and aluminum rise instead.

More- usine de support de concasseur

- et concasseur de sable classé

- laboratoire concasseurs à cône

- poudre de calcite raymond parties de l usine

- facteurs affectant l'efficacite du broyeur a marteaux Sechesable

- groupes de concasseurs de pierres

- en pierre concasseur de travail étude de cas

- Concasseur à Percussion Oakland

- broyage du sable machine de moulin

- equipamentos britadores venda em Chennai

- temperature control cement grinding

- dimensionamento de moinhos de bola

- machine de concasseur de pierre de broyeur de roche à main

- processus de fabricant concasseur xp

- extraction et exploiter des minerais madagascar