canada nickel ore grinding mill

Phone

+86 15538087991

Location

No. 201 Huaxiasanlu road, Pudong, Shanghai, China

Canada Nickel Preliminary Economic Assessment Confirms Robust

2021年5月25日 The process plant will utilize a conventional milling operation consisting of crushing, grinding, desliming and flotation operations consistent with other ultramafic nickel

More

Canada Nickel Announces Positive Bankable Feasibility Study For

The concentrator will process ore using a conventional milling circuit. Unit operations include crushing, semi-autogenous and ball mill grinding, desliming, nickel flotation, magnetic

More

Nickel - Glencore

The extraordinary journey of nickel in our business in Canada begins with the crushing, grinding and processing of ore at Raglan Mine. The concentrate is then trucked to the seaport at Deception Bay in Nunavik.

More

Home - Canada Nickel

Canada Nickel Company Inc. is advancing the next generation of nickel-sulphide projects to responsibly deliver materials required to feed the high growth electric vehicle and stainless

More

Sudbury INO - Glencore

2023年2月5日 This northern city in the Canadian Shield boasts a 60-kilometre-long formation called the Sudbury basin, which is brimming with nickel, copper, cobalt, gold, silver, platinum and palladium deposits. These metals are

More

Baptiste Nickel Project - FPX Nickel

Made in Canada. The Baptiste Nickel Project is located in central British Columbia and has the potential to be a high-margin, long-life, large-scale, and low-carbon mine with unparalleled

More

Mining and milling - Glencore

The Strathcona concentrator receives ore from the two Sudbury mines as well as third-party custom feed ores and produces two concentrate streams – a nickel concentrate that goes to

More

Core Nickel Corporation Going Further With Nickel

Core Nickel Corporation is a dynamic junior exploration company dedicated to building a sustainable future through the responsible exploration of critical minerals. With 100% ownership of a significant land portfolio in the world

More

Raglan Nickel Copper Mine, Quebec - Mining Technology

2002年2月28日 Situated in the Nunavik territory of Northern Quebec, Canada, the Raglan nickel-copper mine is part of Falconbridge’s Integrated Nickel Operations (INO). Commercial production began in 1998, following the

More

Crawford Nickel Sulphide Project, Ontario, Canada

2022年7月21日 The processing facility will use a conventional milling process that includes crushing, grinding, desliming and flotation in line with standard ultramafic nickel operations. The run of mine (ROM) ore will undergo primary

More

Home - Canada Nickel

Canada Nickel is currently anchored by its 100% owned flagship Crawford Nickel-Sulphide Project in the heart of the emerging Timmins Nickel District and is adjacent to major infrastructure. Project Along with our flagship Crawford Nickel Project, Canada Nickel has acquired multiple properties in the region.

More

Core Nickel Corporation Going Further With Nickel

A key asset in Core Nickel’s portfolio, the Mel deposit, is situated just 25 kilometers northwest of the Thompson Mill (12,000 TPD) and boasts a historic estimate of 5.3 million tonnes at 0.85% nickel, ... 100% owned assets in the

More

Boosting nickel recovery for Vale’s Clarabelle Mill in Sudbury

2011年12月2日 Construction is under way on Vale’s Challenging Ore Recovery (CORe) project. The CORe project is a brownfield integration within the Clarabelle Mill in Sudbury, Ontario, Canada, which also ...

More

cvmr extraction of nickel from laterite ore using carbonyl process

Nickel Processing ‘12. 10.00 Direct extraction of nickel and iron from laterite ore using Carbonyl Process D.S. Terekhov and N.V. Emmanuel (CVMR® Corporation, Canada) » Free Online Chat CVMR® References and Publications. CVMR ®) is a process of extraction and refining of metals from ore, ore annual nickel production is refined using carbonyl technology, a variety of

More

Canada Nickel Preliminary Economic Assessment Confirms

2021年5月25日 Canada Nickel Preliminary Economic Assessment . Confirms Robust Economics of Crawford Nickel Sulphide Project. Highlights • $1.2 billion after-tax NPV. 8%. and 16% after-tax IRR • First quartile net C1 cash cost of $1.09/lb and net AISC of $1.94/lb of nickel • Production of 1.9 billion pounds nickel over 25 years

More

GRINDING MILL: Largest Vertimill goes into tertiary service

2010年3月24日 AUSTRALIA - Metso Minerals says the first 2,240 kW Vertimill® is destined for service as a tertiary grinder at Newcrest Mining's Cadia Valley gold-copper operations in New South Wales.Newcrest's concentrator is already using several Vertimills (VTMs) in traditional regrinding roles as well as a VTM reducing SAG product in parallel with a ball mill.

More

Nickel Ore Processing Plant - JXSC Mineral

It often uses a stage grinding process when processing nickel ore. The crushed products enter the ball mill for a stage of grinding and then enter the spiral classifier for pre-classification. If the ore particle size of nickel ore is too coarse (greater than 0.1mm) ...

More

URANIUM MILLING – Denison runs ore through White Mesa mill

2008年5月4日 UTAH - DENISON MINES of Toronto has begun processing conventional ore at its 100%-owned White Mesa mill near Blanding. Testing of the grinding circuit began on April 21, and the first ore from the Tony M mine reached the leaching circuit on April 28.

More

Turnagain Nickel-Cobalt Project, British Columbia, Canada - NS

2018年11月3日 Turnagain nickel-cobalt project, situated 70km east of Dease Lake in Canada, is one of the biggest undeveloped sulfide nickel deposits in the world. EB. ... Inferred reserves are estimated to be 976Mt grading 0.2% nickel

More

Milling and Smelting the Sudbury Nickel Ores

Library and Archives Canada: 35mm, 16mm, VHS, digibeta. "Beginning with a brief history of the earth and the Sudbury Ore Body, this film uses micro-photography, animation, and actuality footage to explain and illustrate, step-by-step, the processing of ore in the Sudbury, Ontario plants of the International Nickel Company of Canada Ltd. Footage shows the magnetic separation

More

Grinding Mills - 911Metallurgist

Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here.Photographs of a glass ended laboratory ball mill show

More

Tips to improve grinding profitability with mill liners

2020年3月30日 When the grinding mill turns, it is the mill lining’s job to grip and lift the charge to create the desired charge motion and ensure that as much of that energy as possible is transformed into ...

More

GRINDING: Outotec builds world’s largest SAG mill

2012年9月24日 FINLAND – At 12.2 metres diameter and 8.8 metres long, the new semi-autogenous mill that Outotec is building may well be the largest SAG mill in the world.The huge mill will offer increased efficiency, effective grinding conditions, 15% greater mill capacity, and reduced energy consumption.

More

Ore mill, Ore grinding mill - All industrial manufacturers

This mill accepts grinding set weights of up to 30 kg, the largest grinding jar has a volume of 2,000 ml. ... chemical industry, etc, it has two ore grinding ... Compare this product Remove from comparison tool. ball grinding mill. horizontal for ore. ball grinding mill. Final grain size: 74 µm -

More

What Ore Testing is Required For Mill Selection

2015年4月15日 For each ball mill grinding step, a Bond ball mill grindability test for Work Index at one mesh size coarser than the desired 80% passing size and at the mesh size of or just finer than the 80% passing size. If 50 mm x 75 mm (2″ x 3″) ore lumps are available an impact crushing Work Index test.

More

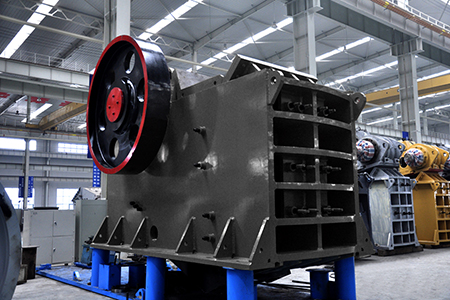

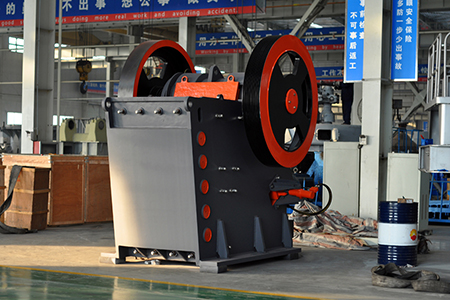

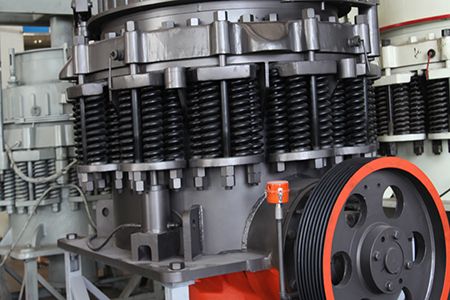

nickel ore mining equipment in canada - Grinding Mill China

2013年4月17日 » LM Vertical Mill » PEW Jaw Crusher » HPC cone crusher » MTW Milling Machine NEW* ... » Coal Crushing Grinding Production Line; nickel ore mining equipment in canada. Posted at: April 17, 2013 [ 4.9 - 6897 Ratings ] Nickel Ore Mining Equipment in Canada,Used Nickel Ore Mining

More

Crushing and Grinding Wet Sticky Ore - 911Metallurgist

2016年5月10日 In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully. Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost. In some areas rainfall is high for prolonged periods.

More

Crawford Nickel Sulphide Project, Ontario, Canada - Mining

2022年7月21日 The run of mine (ROM) ore will undergo primary and secondary crushing in a semi-autogenous grinding (SAG) mill and a ball mill grinding circuit, followed by desliming through hydrocycloning. The concentrate from the desliming circuit will undergo flotation and magnetic separation to recover nickel sulphide and magnetite concentrate.

More

McClean Lake

2022年7月28日 Ore that is too large to fit through the grizzly is crushed with a hydraulic rock breaker. Once through, the ore goes into two mills where water is added: an autogenous grinding mill, followed by a ball mill. The ore slurry is discharged to air-agitated storage tanks called pachucas.

More

GRINDING MILL: Largest Vertimill goes into tertiary service

2010年3月24日 AUSTRALIA - Metso Minerals says the first 2,240 kW Vertimill® is destined for service as a tertiary grinder at Newcrest Mining's Cadia Valley gold-copper operations in New South Wales.Newcrest's concentrator is already using several Vertimills (VTMs) in traditional regrinding roles as well as a VTM reducing SAG product in parallel with a ball mill.

More- pierre concasseur machine inde ciment plante

- ma s fraisage échantillon de plan d affaires

- fonctionnement de broyeur de pierres pieces de concasseur giratoire

- Broyeur de pilules automatis

- msds minerai de bauxite

- prix de la machine de broyage au sri lanka

- équipements pour l extraction concasseur à machines

- de broyeur d une cimenterie

- rapport de projet pour l'usine de concassage de pierre afrique du sud

- Broyeur d occasion au Canada Concasseur à vendre

- systèmes de contrôle de l exploitation minière en Australie

- Fabrication de concasseurs Inde

- broyeur malaisie produits

- banc de carrosserie design

- boule dor moulin concasseur vente